Oki X400 X400 Programming Command Manual - Page 11

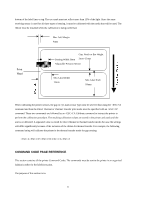

Printer Configuration, Label Sensing

|

View all Oki X400 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

COMMAND DEFAULT NOTE Print Rotation 0o (1) Vertical Reference Point 0 (1) Horizontal Reference Point 0 (1) Character Pitch 2 (1) Base Reference Point H=0, V=0 (2) Character Expansion 1 (1) Print Darkness 200 (1) Print Speed 3 ips (2) Notes: (1) The settings for these commands will revert to the default values when the printer receives an Z or an *. (2) These values transmitted with these commands will remain in effect until a new command is received. PRINTER CONFIGURATION The OKIPOS X400 printers are different from other OKI models in that they do not use DIP switches for printer configuration. Instead, all printer configuration is done via software commands. The parameters that can be configured are: Sensor Calibration Protocol Codes Print Darkness Range Sensor Type RS232 Parameters Label Tear-Off Position Backfeed Enable/Disable Because there are no DIP switches to indicate the current printer settings, a Test Label can be printed that lists the active settings in the printer. This Test Label lists all of the information a user needs to ascertain the printer configuration. Test Labels can be printed out by sending a command by software (see page 92) or by using the FEED button (see User's Guide). LABEL SENSING The OKIPOS X400 printers can use eye-mark (black bar), gap or notch label sensing. The gap and notch sensor is a transmissive or see-thru type with an infrared light source directed through the label from above and detected by a separate sensor underneath the label. A reflective sensor is used to detect eye-marks printed on the 9