Brother International HL-720 Service Manual - Page 116

Ch3 Disassembly, 1. Safety Precautions

|

View all Brother International HL-720 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 116 highlights

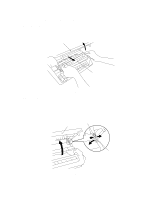

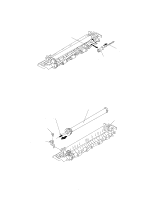

CHAPTERIII DISASSEMBLY AND REASSEMBLY 1. SAFETY PRECAUTIONS To avoid creating secondary problems by mishandling, be careful to follow the precautions below during maintenance work. (1) Always turn off the power switch and unplug the power cord from the power outlet before accessing any parts inside the printer. (2) Be careful not to lose screws, washers, or other parts removed during servicing. (3) Be sure to apply grease to the gears and other positions as specified in this chapter. (4) When using soldering irons or other heat-generating tools, take care not to damage wiring, PCBs and covers. (5) Before handing the PCBs, touch a metal part of the equipment to discharge any static electricity charged in your body, or else electronic parts or components may be damaged. (6) When transporting PCBs, be sure to wrap them in conductive sheet to prevent static damage. (7) Be sure to replace self-tapping screws correctly, if removed during servicing. Unless otherwise specified, tighten screws to the following torque values. TAPTITE, BIND or CUP B M3 : 6kgf • cm M4 : 9kgf • cm TAPTITE, BIND S M3 : 9kgf • cm SCREW M3 : 7kgf • cm M4 : 10kgf • cm (8) When connecting or disconnecting cable connectors, hold the connector body, not the cables. If the connector has a lock, release the connector lock first then disconnect the cable. (9) After a repair, do not only check the repaired portion but also check the connectors and that other related portions are functioning properly before doing operation checks. III-1