Oki ML490 Maintenance Manual - Page 49

performed when the rear sensor lever intercepts the sensor.

|

View all Oki ML490 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 49 highlights

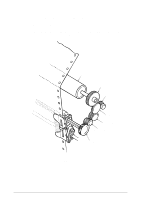

2.2.6 Paper detection mechanism (See Figure 2-14.) (1) Cut sheet detection When the cut sheet is inserted, the point A is pushed backward and the paper near end lever B rotates counter clockwise (CCW). At this time, the rear sensor lever rotates counterclockwise (CCW), the rear sensor lever and pulls out of the rear and top paper end sensor to detect that the sheet is provided. The procedure for the paper end is made in the reverse order, that is, its detection is performed when the paper end sensor is blocked. (2) Rear feed detection When the sheet is fed from the push tractor, the point B is pushed to the front side and the paper near end lever A rotates clockwise (CW). At this time, the rear sensor lever rotates counterclockwise (CCW), and pulls out of the rear and top paper end sensor to detect that the sheet is provided. The procedure for the paper end is made in the reverse order, that is, its detection is performed when the rear sensor lever intercepts the sensor. (3) Bottom feed detection When the sheet is fed from the bottom, the point C rotates clockwise (CW). When the bottom sensor lever rotates clockwise (CW), it pulls out of the bottom paper end sensor to detect that the sheet is provided. The procedure for the paper end is made in the reverse order, that is, its detection is performed when the bottom sensor lever intercepts the sensor. Paper end sensor Sensor lever A Shaded portion B Paper end lever Figure 2-14 Bottom paper end lever 42114101 Rev.1 49 /