Brother International HE-800A Instruction Manual - English - Page 101

Skipped stitches

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 101 highlights

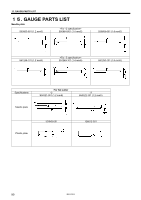

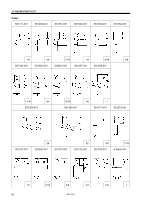

16. TROUBLESHOOTING Cause Rotary hook Upper thread amount Bobbin case Check Needle bar height and needle bar lift amount Gap between needle and rotary hook Rotary hook lubrication Thread twisted around rotary hook Arm thread guide position Damaged outside of bobbin case and bent bobbin holder spring, etc. Remedy Adjust the needle and hook timing. 1. Adjust the needle bar height to "1" on the gauge. 2. Adjust the needle bar lift amount to "2" on the gauge. Adjust the gap between needle and rotary hook to 0.01 - 0.08 mm. (Adjust to as large as possible without causing skipped stitches to occur.) * Check that rotary hook point does not strike needle in zigzag motion. Too small quantity of lubrication oil will cause thread breakage. Adjust the quantity of lubrication oil. The lubrication holes between rotary hook and rotary hook joint do not match up. Remove any twisted thread from the inner and rotary hook. Adjust the arm thread guide position Polish with buff or replace the part. * Use the HE-800A bobbin case. Page 72, 73 73 25 73 63 - 16-2. Skipped stitches Cause Needle Thread spring take-up Work clamp Rotary hook Check Needle facing Needle installation height Bent needle Blunt needle tip or burr Thin needle Thread take-up spring tension and stroke Work clamp pressure Relation between work clamp assembly and sewing length Blunt rotary hook point Needle bar height and needle bar lift amount Gap between needle and rotary hook Remedy As viewed from the direction of the face plate, attach needle so that the notched part of needle faces frontward. Insert the end of the needle shank so that it touches the top edge of the needle hole of the needle bar. Replace needle Replace needle Use a needle with a count that matches the thread and material. Loosen the thread take-up spring tension or shorten the stroke to such a degree that does not cause double hooking. Adjust it while checking bar tacking stitches. Increase work clamp pressure. * The standard height of the adjustment screw is approximately 30 mm, so tighten it further than this. Replace work clamp assembly that fits for sewing length. * When using knits or woven materials, replace the parts with the -3 specification parts: Length feed plate (for specification -3), work clamp assembly (for knits), needle plate 1.2 (for specification -3) Polish with buff or replace the part. Adjust the needle and hook timing. 1. Adjust the needle bar height to "1" on the gauge. 2. Adjust the needle bar lift amount to "2" on the gauge. Adjust the gap between needle and rotary hook to 0.01 - 0.08 mm. (Adjust to as large as possible without causing skipped stitches to occur.) * Check that rotary hook point does not strike needle in zigzag motion. Page 57 63 74 - 72, 73 73 93 HE-800A