Brother International HE-800A Instruction Manual - English - Page 94

supply circuit board are properly connected.

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 94 highlights

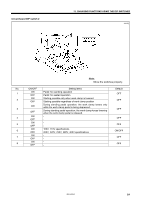

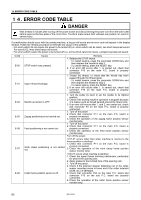

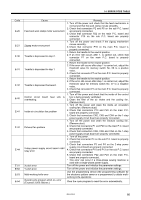

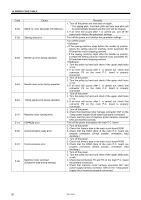

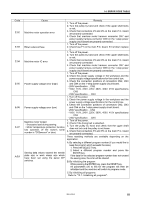

14. ERROR CODE TABLE Code E-20 E-21 E-30 E-31 E-32 E-40 E-41 E-42 E-44 E-51 E-52 E-53 E-54 Cause Feed and work clamp motor overcurrent Zigzag motor overcurrent Treadle is depressed to step 2. Treadle is depressed to step 1. Treadle is depressed backward. Control circuit board heat sink is overheating. Inside air circulation fan problem Exhaust fan problem 2-step power supply circuit board +55V relay error X pitch error Y pitch error Multi-working knife error Overall cycle program stitch no. error (Exceeds 3,000 stitches.) Remedy 1. Turn off the power and check that the feed mechanism is normal and that the work clamp moves smoothly. 2. Check that connectors P2 and P5 on the sub P.C. board are properly connected. 3. Check that connector P22 on the main P.C. board and connector P10 on the sub P.C. board are properly connected. 1. Turn off the power and check if the zigzag mechanism moves smoothly. 2. Check that connector P16 on the main P.C. board is properly connected. 1. Return the treadle to the neutral position. 2. If an error still occurs after 1. is carried out, check that connector P7 on the main P.C. board is properly connected. 1. Return the treadle to the neutral position. 2. If the error still occurs after step 1 is carried out, adjust the threshold value for memory switch No. 08 to a positive value. 3. Check that connector P7 on the main P.C. board is properly connected. 1. Return the treadle to the neutral position. 2. If the error still occurs after step 1 is carried out, adjust the threshold value for memory switch No. 07 to a negative value. 3. Check that connector P7 on the main P.C. board is properly connected. 1. Turn off the power and check that the inside of the control box is being properly ventilated. 2. Clean the filter of the air intake and the cooling fan. (Remove dust.) 1. Turn off the power and clean the inside air circulation cooling fan. (Remove dust.) 2. Check that connectors P13 and P20 on the main P.C. board are properly connected. 3. Check that connectors CN2, CN3 and CN4 on the 1-step power supply circuit board are properly connected. 1. Turn off the power and clean the exhaust cooling fan. (Remove dust.) 2. Check that connectors P1 and P20 on the main P.C. board are properly connected. 3. Check that connectors CN2, CN3 and CN4 on the 1-step power supply circuit board are properly connected. 1. Turn off the power. 2. Check that connector P3 on the sub P.C. board is properly connected. 3. Check that connectors P3 and P4 on the 2-step power supply circuit board are properly connected. 4. Check that connectors P10 and P13 on the sub P.C. board are properly connected. 5. Check that connectors P22 and P23 on the main P.C. board are properly connected. * This error can occur if a three-phase sewing machine is used with a single-phase power supply. Turn off the power and initialize the parameter settings. Turn off the power and initialize the parameter settings. Use the programming device (the programming software for the electronic pattern sewer or a programmer) to delete multiworking knife operations. Clear the cycle program to reset the error automatically. HE-800A 86