Brother International HE-800A Instruction Manual - English - Page 112

Imperfect cutter function imperfect material cutting

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 112 highlights

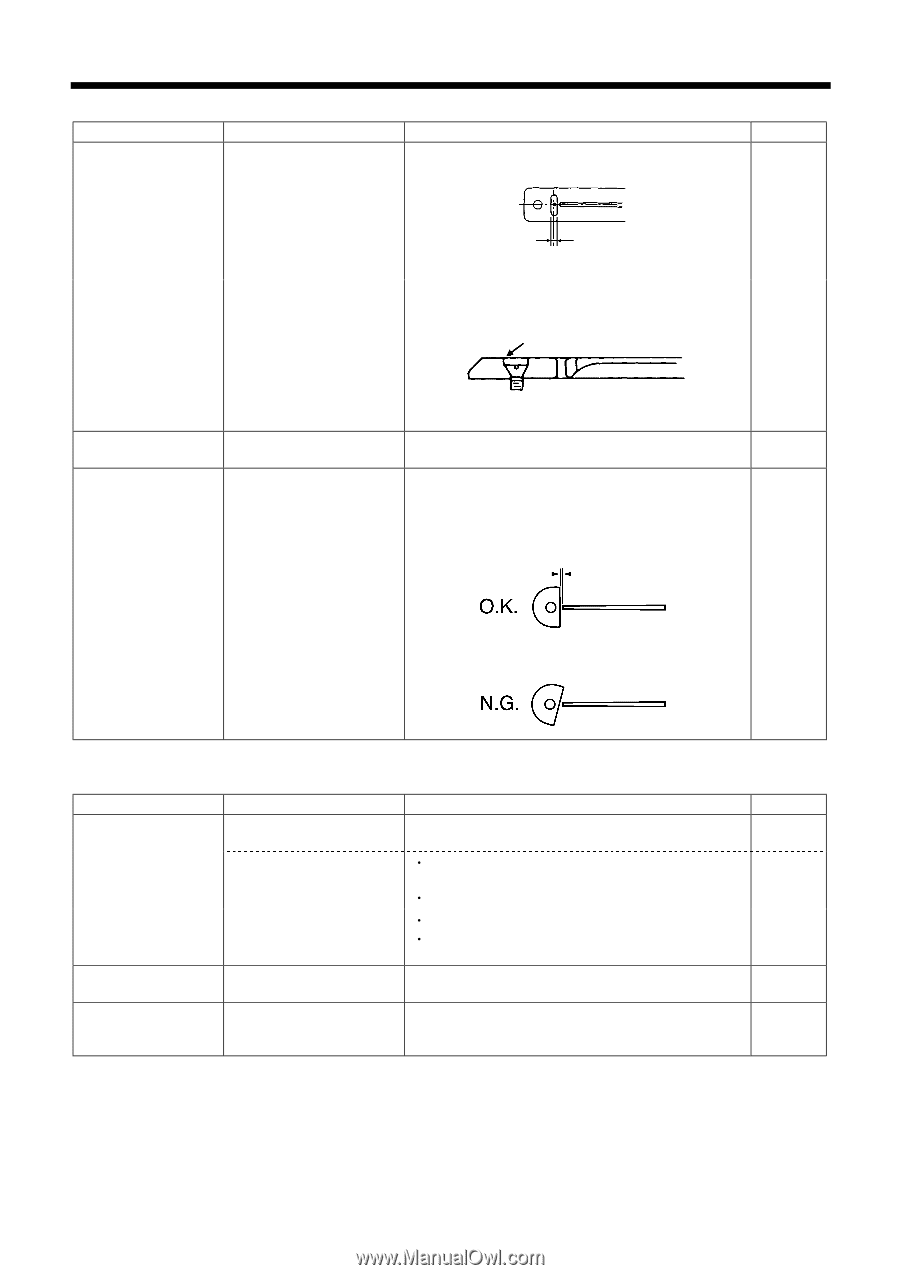

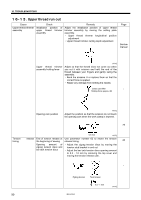

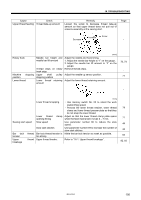

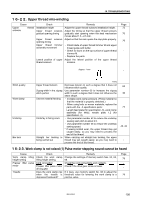

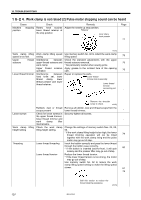

16. TROUBLESHOOTING Cause Needle plate Check Needle plate position Remedy Adjust the forward/back position of the needle plate so that the needle is in the center of the needle hole. Page - Bisect 4014Q Burr on the screw hole Polish with buff. edge (in event of uneven material feeding) Check the chamfered side finishing - (Needle plate cross section) Upper thread trimmer assembly Cutter Needle strikes upper thread trimmer Clearance between needle bar and cutter 4015Q Refer to "16-16. Needle strikes upper thread trimmer". Install the cutter so that the clearance between the needle bar and the cutter is 0.3 mm. * The cutter release section of the needle bar should be at a right angle to the cutter. 102, 103 0.3 mm 74 4016Q Imperfect cutter function (imperfect material cutting) Cause Cutter Cutter solenoid Cutter power Check Installation position of cutter Cutter blade Damage to cutter mechanism parts Loose screws Check for a disconnected cord. Memory switches Remedy Install the cutter so that its edge is aligned with the top of the needle plate. If blade is worn or chipped, sharpen it or replace it. Replace with the special needle plate (optional). Replace any parts that are damaged. Tighten any loose screws. Connect the cords. If the material is heavy and difficult to cut, use memory switch No. 00 to increase the cutting force of the cutter. Page 74 4 79 HE-800A 104