Brother International HE-800A Instruction Manual - English - Page 113

Cutter does not return, Cutter and upper thread scissors touch, Seam is cut

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 113 highlights

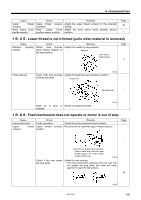

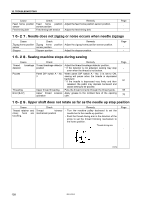

16. TROUBLESHOOTING Cause Solenoid stopper Check Nut Cutter sensor position Remedy Check if the nut is loose, and tighten it securely. Adjust the cutter sensor position. Check if the mounting screws are loose, and tighten them securely. 4.5 ± 0.5 mm Cutter sensor Page - - Cutter bar guide 4017Q Smoothness of cutter Adjust the cutter bar guide so that the cutter operation operates smoothly with no play. - Cutter does not return Cause Cutter Sticks in material Cutter bar guide Check Cutter blade Needle plate Smoothness of operation cutter Remedy If blade is worn or chipped, sharpen it or replace it. Replace with the special needle plate (optional). Adjust the cutter bar guide so that the cutter operates smoothly with no play. Page 4 - Cutter and upper thread scissors touch Cause Upper scissors thread Check Check if the cam opens the stop plate. Remedy Adjust the cam position. * If the feed mechanism operates when the cam has not opened the stop plate, the cutter will bump against the upper thread scissors. Page 76 Seam is cut Cause Length of knife setting Knife space setting Check Length of knife Cutting of zigzag seam Cutter Cutter play Cutter knife bending 4018Q Remedy Set parameter number 02 to the same value as the length of the knife being used. Use parameter number 06 to set the knife X space. Use parameter number 08 to set the knife X position alignment. Adjust the cutter bar guide so that the cutter operates smoothly with no play. Use the cutter holder (option) to prevent the cutter knife from becoming bent. Page 36 36, 37 - - 4019Q 105 HE-800A