Brother International HE-800A Instruction Manual - English - Page 108

Sewing start speed

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 108 highlights

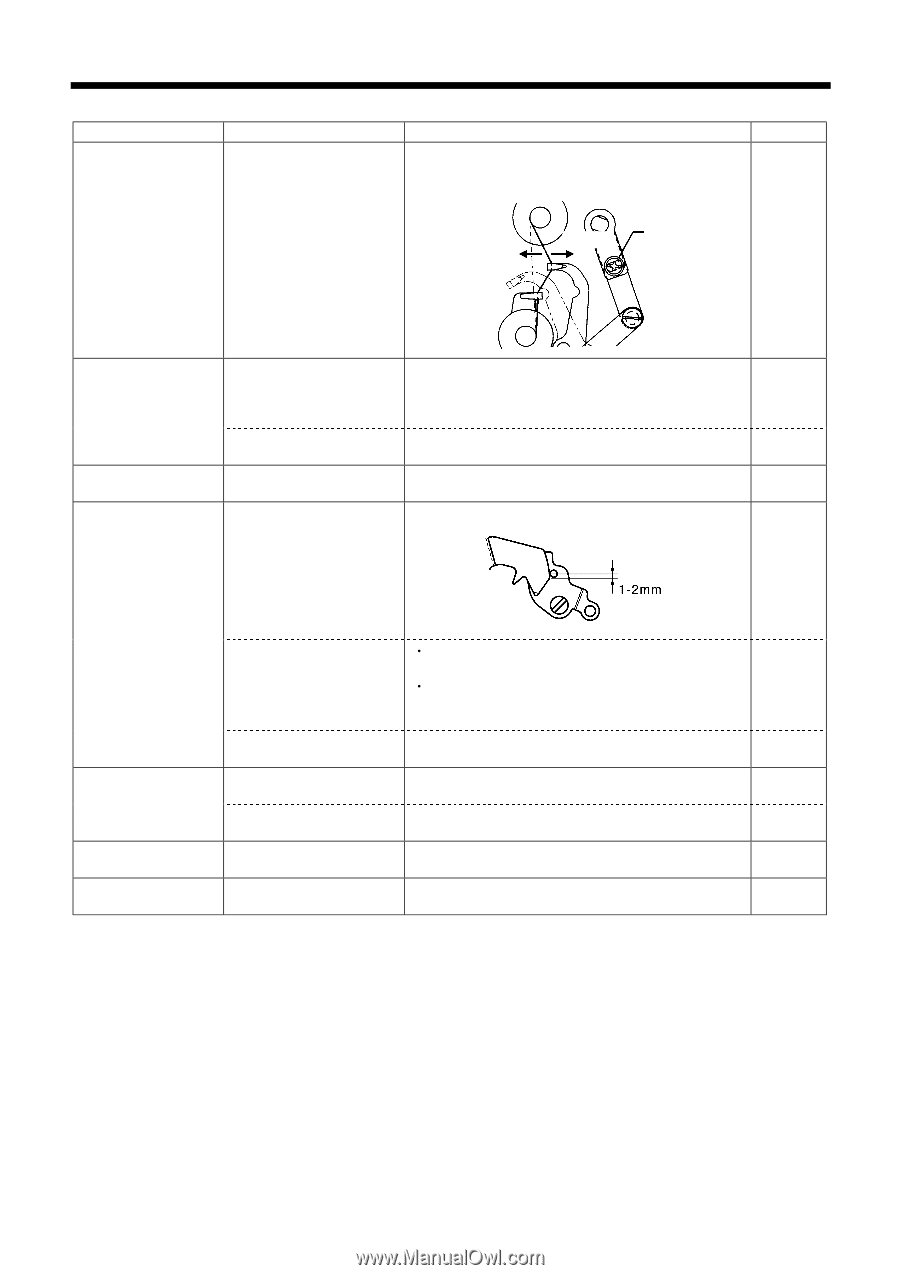

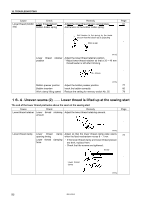

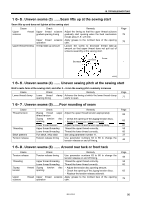

16. TROUBLESHOOTING Cause Check Upper thread feeding Thread take-up amount Remedy Loosen the screw to decrease thread take-up amount so that upper thread does not pull out of scissors assembly at the sewing start. Page Increase Screw Decrease - Rotary hook Machine stopping position Lower thread Needle bar height and needle bar lift amount Thread chips on rotary hook edge Upper shaft pulley stopping position Lower thread retaining amount 4000Q Adjust the needle and hook timing. 1. Adjust the needle bar height to "1" on the gauge. 2. Adjust the needle bar lift amount to "2" on the gauge. Remove thread chips. Adjust the needle up sensor position. Adjust the lower thread retaining amount. 72, 73 77 - Sewing start speed Bar tack tension Upper breakage thread thread Lower thread snapping Lower thread opening timing Slow speed clamp Slow start stitches Bar tack thread tension is too strong. Upper thread breaks. 4003Q Use memory switch No. 02 to retard the work clamp lifting speed. Process the lower thread retainer, lower thread clamp and lower thread presser plate so that they do not snap the lower thread. Adjust so that the lower thread clamp plate opens when the feed mechanism moves 6 - 7 mm. Use parameter number 60 to reduce the slow speed. Use parameter number 59 to increase the number of slow start stitches. Make the bar tack tension as weak as possible. Refer to "16-1. Upper thread breakage". 79 77 44 44 62 92, 93 HE-800A 100