Brother International HE-800A Instruction Manual - English - Page 55

Brother International HE-800A Manual

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 55 highlights

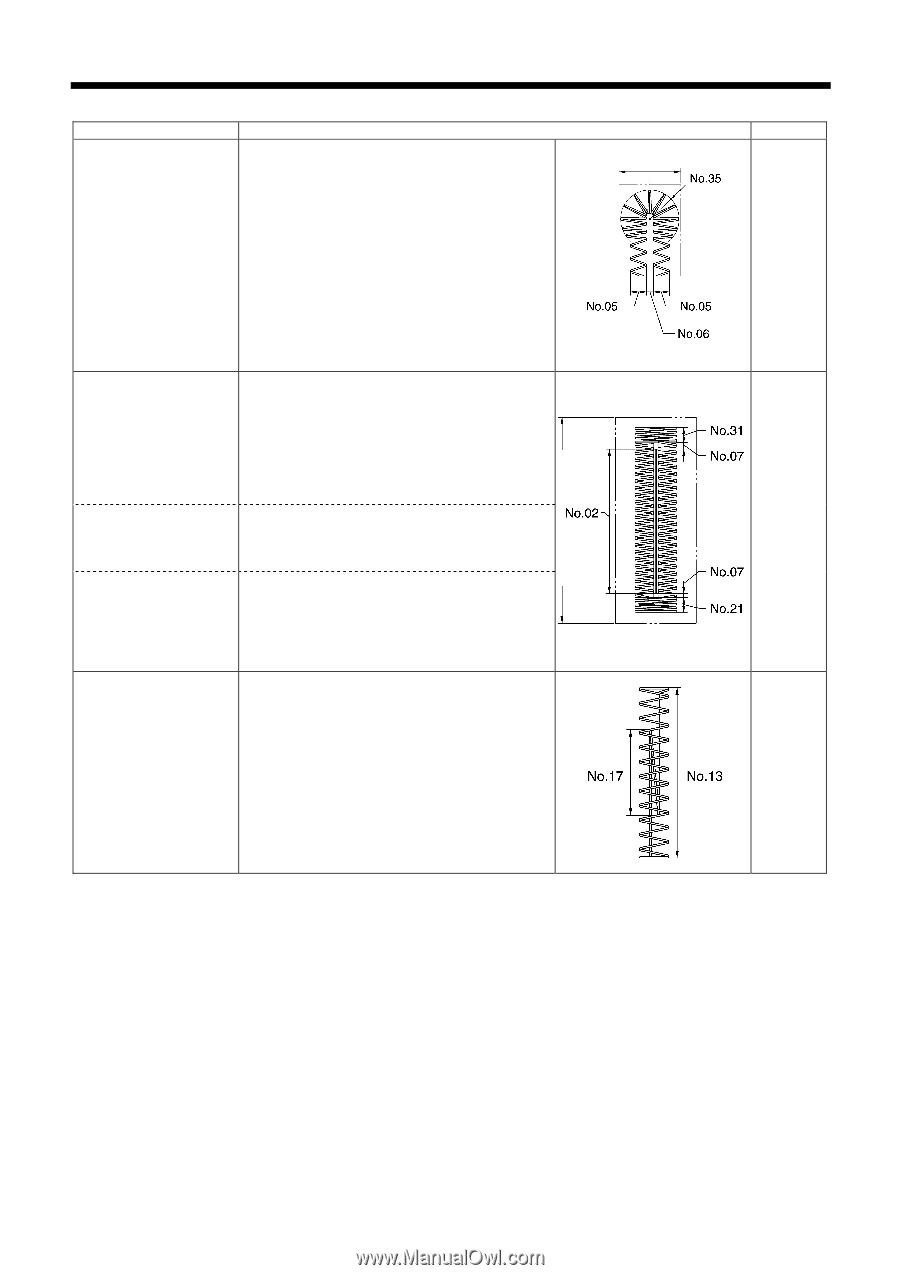

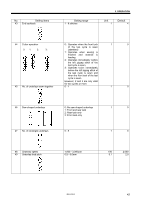

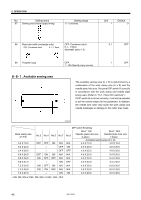

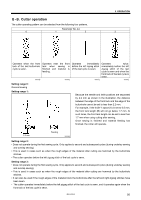

5. OPERATION Symptom Parameter number 35 (Eyelet buttonhole radius) does not become larger or smaller. Cause If the sewing area is 4.0 mm and parameter number 06 (Knife X space) is set to 0.4 mm and parameter number 05 (Zigzag width) is set to 1.5 mm, the eyelet buttonhole radius that can be entered will be a minimum of (1.5 + 1.5 + 0.4) ÷ 2 = 1.7 mm, and a maximum of 4.0 ÷ 2 = 2.0 mm. 4.0 mm Remedy A 1.5 mm Parameter number 02 (Length of knife) does not become larger. Parameter number 07 (Knife Y space) does not become larger. If the sewing area is 32.0 mm and parameter number 07 (Knife Y space) is set to 1.0 mm, parameter number 21 (Front tack length) is set to 1.0 mm and parameter number 31 (Rear tack length) is set to 1.0 mm, the knife length will be 32.0 - 1.0 - 1.0 - 1.0 - 1.0 = 28.0 mm. (The 32.0 mm default setting is 27.8 mm to match the positions of the needle and cutter.) See illustration. Parameter number 21 (Front tack length) and parameter number 31 (Rear tack length) do not become larger. See illustration. Parameter number 13 (Straight bar tack length) does not become smaller. The initial setting for parameter number 13 (Straight bar tack length) is 13.0 mm, and for parameter number 17 (Running length) it is 11.0 mm. At this time, the straight bar tack length cannot be set to less than 11.0 mm. 11.0 mm 1.5 mm 0.4 mm 3925Q A 1.0 mm 1.0 mm 1.0 mm 1.0 mm 3926Q B 13.0 mm 3927Q A. Change the work clamp over to a larger work clamp. Alternatively, change the needle plate to one with a larger hole. Note: Be sure to change the setting for panel DIP switch B also. B. Set parameter number 17 (Running length) to a smaller value and then set the straight bar tack length. 47 HE-800A