Brother International HE-800A Instruction Manual - English - Page 53

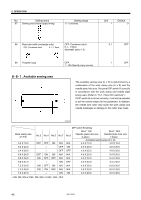

Available sewing area

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 53 highlights

5. OPERATION No. Setting items 67 Sewing end tension apply timing Setting range -5 - 0 stitches Unit 1 Default 0 68 Rear tack width (rectangle only) OFF: Condense stitch 0.1 - 1.5mm OFF: Condense stitch 0.1 - 1.5mm (Normally set to 1.0) 0.1 OFF 69 Program copy Available sewing area OFF, 1 - 90 (Specify copy source) 1 OFF The available sewing area (C x D) is determined by a combination of the work clamp size (A x B) and the needle plate hole size. Set panel DIP switch B correctly in accordance with the work clamp and needle plate being used. (Refer to "13-1. Panel DIP switches".) If DIP switch B is not set correctly, it will not be possible to set the normal values for the parameter. In addition, the needle and cutter may touch the work clamp and needle breakages or damage to the cutter may result. 3921Q Work clamp size (A X B) No.3 No.4 No.5 No.7 5.4 X 19.0 OFF OFF ON N/A 5.4 X 24.5 ∗ OFF 5.4 X 36.0 ∗ OFF 6.8 X 24.5 OFF ON ON N/A 6.8 X 36.0 ON OFF OFF N/A 6.8 X 47.0 ∗ ON 7.3 X 24.5 ON OFF ON N/A 7.3 X 36.0 ON ON OFF N/A 7.3 X 47.0 ∗ ON ∗ ON, ON, ON or OFF, ON, OFF or OFF, OFF, OFF DIP switch B setting No.8 N/A No.6=ON No.6=OFF (Needle plate hole size (Needle plate hole size 5.4mm) 7.3mm) Available sewing area (C x D) 4.0 X 15.0 4.0 X 15.0 ON 4.0 X 20.0 4.0 X 20.0 OFF 4.0 X 32.0 4.0 X 32.0 N/A 4.0 X 20.0 5.4 X 20.0 N/A 4.0 X 32.0 5.4 X 32.0 OFF 4.0 X 40.0 5.4 x 40.0 N/A 4.0 X 20.0 6.0 X 20.0 N/A 4.0 X 32.0 6.0 X 32.0 ON 4.0 X 40.0 6.0 X 40.0 45 HE-800A