HP Latex 560 User Guide - Page 196

Summary of common printing problems

|

View all HP Latex 560 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 196 highlights

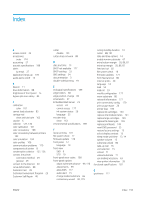

A Summary of common printing problems This is a table of common problems and the parameters that can be changed in order to solve the problem. Some possible side-effects are also shown. For a more detailed treatment of any particular problem, please see the relevant chapter in this guide. Problem Parameter Durability problems, ink smudges, or Curing temperature oily finish Number of passes Inter-pass delay offset Substrate jam, substrate damage, ink Curing temperature smears Vacuum Top and/or bottom margins Edge holders Vertical banding Horizontal banding Coalescence graininess in low-tomedium area fills Vacuum level Take-up reel Clean printheads Number of passes Clean substrate-advance sensor Inter-pass delay offset Align printheads Number of passes Optimizer level Efficiency mode Wiper roller Dirty roll or defective coating Graininess, color misregistration or lack of sharpness Align printheads Clean substrate-advance sensor Change Increase Increase Increase Decrease Increase Increase Use Decrease Use Possible side-effects Substrate jam, substrate damage, ink smears Slower printing Slower printing Less durability (smudges), oily finish Substrate skew, vertical banding if increased too much Waste of substrate The minimum side margins increase slightly, reducing the maximum width of the printed image Substrate jam Increase Slower printing Increase Slower printing Increase Slower printing Increase Reduced gloss in dark area fills. With some substrates, may have no effect on coalescence. Consider using the advanced optimizer check plot to select the best optimizer level. Disable More ink consumption Activate Consider trying a new roll if the wiper roller fails to solve the problem. Some substrates deteriorate during long periods of storage. 190 Appendix A Summary of common printing problems ENWW