Konica Minolta ProJet 160 Cube3 User Guide - Page 88

Gap Verification

|

View all Konica Minolta ProJet 160 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 88 highlights

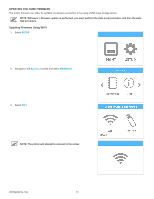

Gap Verification Print a test print from the System 1 menu. Once you have removed it from the print pad, visually inspect the first (bottom) layer of the print and verify the quality. Turn the print upside down and inspect the printing grain. When the gap is optimal, the bottom of the print should appear smooth and the lines should be very light and fused together. Correct Gap The gap is correct when the bottom of the print appears smooth and the lines are tightly fused together. Gap Is Too Large If the lines are more prominent (see the illustration below) and not tightly fused, the gap is too large. Auto Level and Auto Gap should be performed. When the gap is too large, the first layer may begin to fray when removing the print from the print pad. Gap Is Too Narrow When the gap is too narrow, the part may be very difficult to remove from the print pad. In addition, the bottom layers may break off from the rest of the part while removing it. The bottom of the first layer will appear very smooth and shiny with almost no visible lines. NOTE: If the bottom of the part appears shiny, make sure all glue has been removed and then reinspect it. Caution: Damage to the print pad can occur if the gap is too narrow. 3D Systems, Inc. 84