Stihl MS 251 Instruction Manual - Page 39

Cylinder / Crankshaft, Insert the screws 1 - do - test

|

View all Stihl MS 251 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 39 highlights

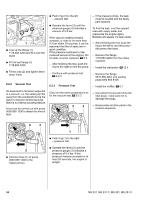

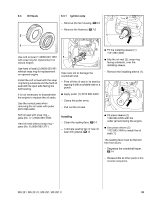

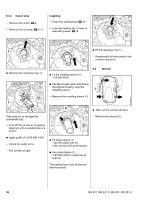

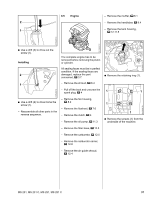

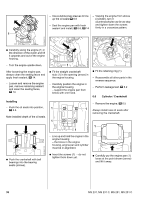

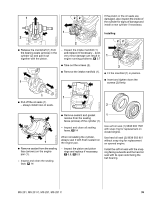

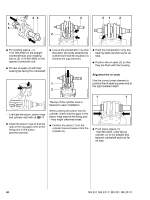

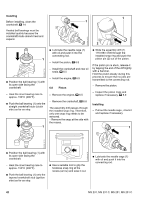

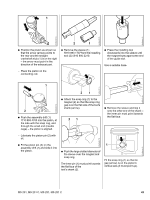

- Use suitable press sleeves to line up the oil seals b 6.6 - Seal the engine pan with fresh sealant and install, b 6.6, b 14 - Viewing the engine from above (cylinder), turn it counterclockwise as far as stop and tighten down the screws firmly in a crosswise pattern. 1 2310RA093 TG 2310RA096 TG 2310RA087 TG : Carefully swing the engine (1) in 1 the direction of the clutch and lift it upwards and out of the engine housing. - Turn the engine upside down. After loosening the engine pan, always clean the sealing faces and apply fresh sealant, b 14. - Loosen and remove the engine pan, remove remaining sealant and clean the sealing faces, b 14 Installing - Push the oil seals into position, b 6.6 Note installed depth of the oil seals. 1 : Fit the straight crankshaft stub (1) in the opening (arrow) in the engine housing. - Carefully position the engine in the engine housing - support the engine pan from below with one hand. 1 1 1 1 : Fit the retaining ring (1). - Reassemble all other parts in the reverse sequence. - Perform leakage test, b 6.2 6.6 Cylinder / Crankshaft - Remove the engine, b 6.5 Always install new oil seals after removing the crankshaft. 1 2310RA427 TG 2310RA092 TG 2310RA098 TG - Line up and hold the engine in the engine housing - the bores in the engine housing, engine pan and cylinder must be in alignment. : Push the crankshaft with ball bearings into the bearing seats (arrows). : Insert the screws (1) - do not tighten them down yet. : Carefully pry the engine pan (1) loose at the point shown (arrow) and lift it away. 38 MS 231, MS 231 C, MS 251, MS 251 C