Stihl MS 251 Instruction Manual - Page 96

Adjusting the Carburetor, 12.7.1 Basic Setting, to 3, 300 rpm.

|

View all Stihl MS 251 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 96 highlights

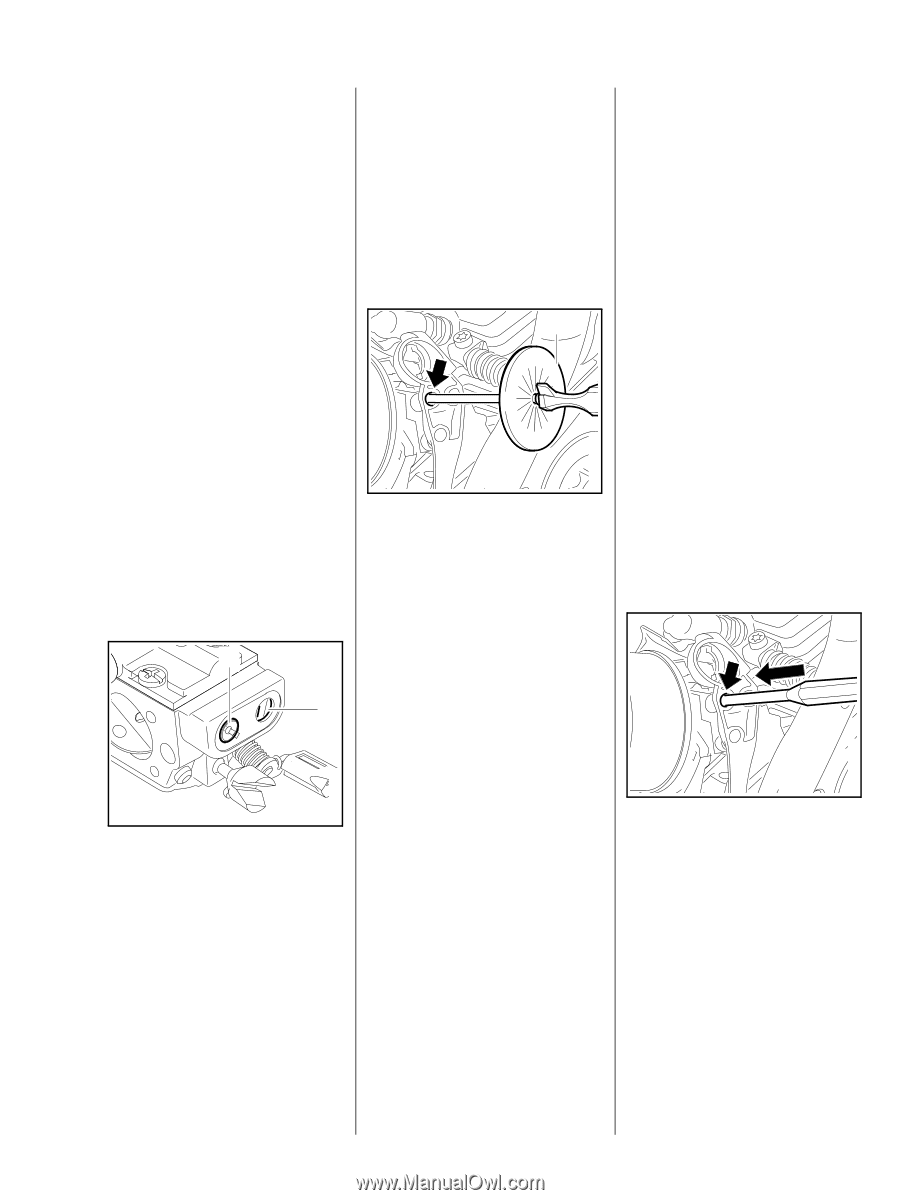

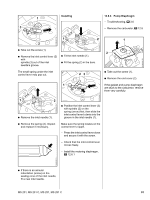

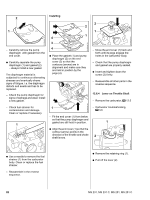

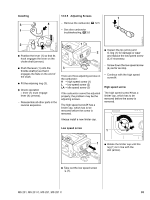

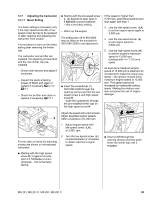

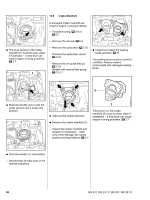

12.7 Adjusting the Carburetor 12.7.1 Basic Setting The basic setting is necessary only if the high speed screw (H) or low speed screw (L) has to be replaced or after cleaning and adjusting the carburetor from scratch. It is necessary to carry out the basic setting after removing the limiter cap. The carburetor and air filter are installed, the adjusting screws fitted and the new limiter cap preinstalled. - Check chain tension and adjust if necessary. - Inspect the spark arresting screen (if fitted) and clean or replace if necessary, b 3.7 or b 6.1 - Check the air filter and clean or replace if necessary, b 12.1 1 2 : Starting with the low speed screw L (2) against its seat, open it 1 full turn counterclockwise - this is the basic setting. - Warm up the engine. The setting disc 5910 893 6600 may be fitted on the screwdriver 5910 890 2306 to aid adjustment. 1 2 : Insert the screwdriver (1) 5910 890 2306 through the opening (arrow) and into the low speed screw L and high speed screw H - push the screwdriver through the pre-installed limiter cap on the high speed screw H. Adjust idle speed with a tachometer. Adjust specified engine speeds within a tolerance of ± 200 rpm. 14 12 0 10 8 4 6 2310RA283 TG If this speed is higher than 3,700 rpm, abort the procedure and start again with step 1. 3. Use the idle speed screw (LA) to set the engine speed again to 3,300 rpm. 4. Use the low speed screw (L) to set engine speed to 2,800 rpm. 5. Use the high speed screw (H) to set the engine's maximum speed to 13,000 rpm. (starting with H = 1 1/2 turns open). As soon as a maximum engine speed of 13,000 rpm is obtained, do not attempt to make the mixture any leaner - the ignition module limits maximum engine speed to 13,000 rpm. This speed cannot be increased by making the setting leaner. Making the mixture overlean increases the risk of engine damage. 2310RA284 TG 1. Adjust engine speed with idle speed screw (LA), to 3,300 rpm. 2310RA282 TG For the sake of clarity the adjusting screws are shown on the exposed carburetor. : Starting with the high speed screw H (1) against its seat, open it 1 1/2 turns counterclockwise - this is the basic setting. 2. Turn the low speed screw (L) counterclockwise or clockwise to obtain maximum engine speed. : Insert a drift through the opening (arrow) and then push home the limiter cap until it engages. MS 231, MS 231 C, MS 251, MS 251 C 95