Stihl MS 251 Instruction Manual - Page 42

Bearings / Crankshaft,

|

View all Stihl MS 251 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 42 highlights

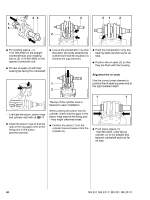

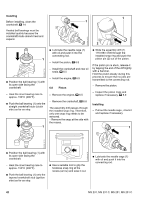

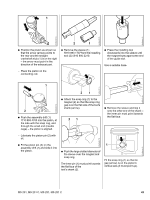

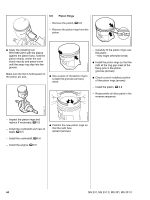

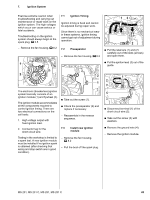

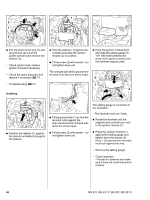

2710RA114 TG : Place the engine pan (1) on the cylinder's sealing face. - Press the engine pan carefully 1 into position so that the sealant is evenly distributed. a 938RA098 TG : Apply a bead of sealant to the engine pan so that it is about 2 - 3 mm high (a). Take care not to damage the crankshaft stubs. - Install the engine, b 6.5 6.7 Bearings / Crankshaft : Pull the ball bearing (1) off the tapered crankshaft stub (ignition side). Make sure the sealant does not project into the crankcase. - Remove the engine, b 6.5 - Remove the crankshaft and pull off the oil seals, b 6.6 - Remove the piston, b 6.8 1 2710RA115 TG : Apply sealant to the groove in the sealing face, b 14 Do not coat oil seals with sealant. 2 1 2310RA111 TG 1 : Pull the ball bearing (1) off the straight crankshaft stub (clutch side). 2710RA113 TG : Pull out the needle cage (1), check it and replace if necessary. The crankshaft, connecting rod and needle bearing form an inseparable unit. When fitting a replacement crankshaft, always install new ball bearings and oil seals. 2310RA112 TG 3 : Position the engine pan (1) so that the tab (2) lines up with the shoulder (3) on the cylinder. MS 231, MS 231 C, MS 251, MS 251 C 41