Stihl MS 251 Instruction Manual - Page 90

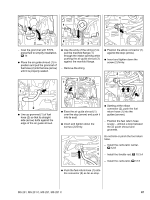

Leakage Test, bar 80 kPa.

|

View all Stihl MS 251 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 90 highlights

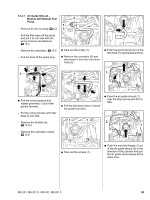

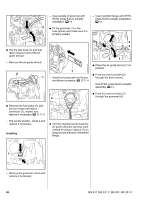

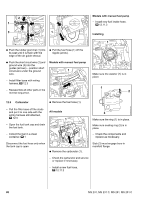

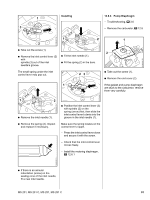

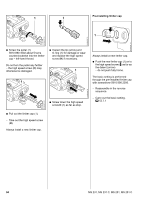

1 All models 2 - Install the filter base, b 12.3 - Install the air filter, b 12.1 : Push the carburetor (1) over the studs (arrows) so that ends of studs are flush with carburetor body. 2 1 : Push the fuel hose (1) onto the nipple (2) so that the tab (arrow) faces the throttle shaft lever and locates uniformly on the nipple. - Push the carburetor fully home. Models with manual fuel pump 1 : Push the new fuel hose (1) onto the nipples (arrows). 2310RA356 TG 2310RA355 TG 2310RA354 TG 2310RA255 TG - Check operation - Set throttle trigger to full throttle position, the throttle shutter must be fully open. 1 - Reassemble all other parts in the - Push the pressure hose of pump reverse sequence. 0000 850 1300 onto the nipple. 12.5.1 Leakage Test In the case of problems with the carburetor or fuel supply system, also check and clean or replace the tank vent, b 12.10 The carburetor can be tested for leaks with the pump 0000 850 1300. : Push the ring (1) to the right and pump air into the carburetor until the pressure gauge (2) indicates a pressure of about 0.8 bar (80 kPa). If this pressure remains constant, the carburetor is airtight. However, if it drops, there are three possible causes: - Remove the carburetor, b 12.5 1. Metering diaphragm or gasket damaged, replace if necessary, b 12.6.1 1 2. The inlet needle is not sealing (foreign matter in valve seat, sealing cone of inlet needle is damaged or inlet control lever is sticking, remove to clean, b 12.6.2 2310RA254 TG 3. Pump diaphragm or gasket damaged, replace if 2 necessary, b 12.6.3 : Push the fuel hose (1) 1110 141 8600 on to the nipple (2) 0000 855 9200. : Push the fuel hose with nipple onto the carburetor's fuel stub (arrow). - Test the tank vent if necessary, b 12.10.1 - After completing the test, push the ring (1) to the left to vent the system and then pull the fuel hose off the carburetor. - Install the filter base, b 12.3 - Reassemble all other parts in the reverse sequence. MS 231, MS 231 C, MS 251, MS 251 C 89