Brother International Isodore„ Innov-ís 5000 Users Manual - English - Page 95

Sewing Stretch Fabrics, Odd Shaped Buttons/Buttons that do, not Fit into the Button Holder Plate

|

View all Brother International Isodore„ Innov-ís 5000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 95 highlights

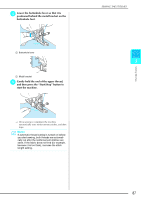

Memo For keyhole buttonholes, use the eyelet punch to make a hole in the rounded end of the buttonhole. Then insert a pin along the inside of one of the bar tacks, insert a seam ripper into the hole made with the eyelet punch, and cut towards the pin. SEWING THE STITCHES c Once sewing is completed, gimp thread to remove any gently pull the slack, and trim off any excess. b a a Eyelet punch Memo After using the seam ripper to cut open the threads over the buttonhole, trim off the threads. 3 Utility Stitches b Basting pin ■ Odd Shaped Buttons/Buttons that do ■ Sewing Stretch Fabrics not Fit into the Button Holder Plate When sewing on stretch fabric with or , Use the markings on the presser foot scale to set the size of the buttonhole. One mark on the presser foot sew the buttonhole stitches over a gimp thread. scale equals 5 mm (approx. 3/16 inch). Add the button diameter and thickness together, and a Hook the gimp thread onto the back of presser foot "A". Insert the ends into the then set the plate at the calculated value. grooves at the front of the presser foot, and then temporarily tie them there. b a c d a a Upper thread b Lower the presser foot and start sewing. Memo Set the width of the satin stitches to the width of the gimp thread, and set the buttonhole width to be 2-3 times the width of the gimp thread. a Presser foot scale b Button holder plate c Completed measurement of diameter + thickness d 5 mm (approx. 3/16 inch) Memo For example, for a button with a diameter of 15 mm (approx. 9/16 inch) and a thickness of 10 mm (approx. 3/8 inch), the scale should be set at 25 mm (approx. 1 inch). a b a 10 mm (approx. 3/8 inch) b 15 mm (approx. 9/16 inch) 83