Brother International MFC 7440N Users Manual - English - Page 30

Types of paper to avoid, Envelopes, Envelopes can be fed from manual feed slot - paper jam problem

|

UPC - 012502620631

View all Brother International MFC 7440N manuals

Add to My Manuals

Save this manual to your list of manuals |

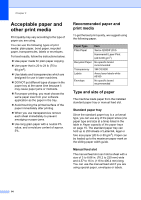

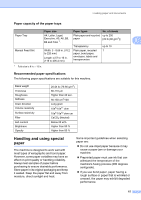

Page 30 highlights

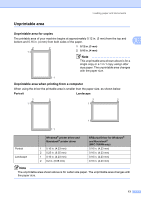

Chapter 2 Types of paper to avoid 2 CAUTION Some types of paper may not perform well or may cause damage to your machine. DO NOT use paper: • that is highly textured • that is extremely smooth or shiny • that is curled or warped 1 1 1 0.08 in. (2 mm) • that is coated or has a chemical finish • that is damaged, creased or folded • that exceeds the recommended weight specification in this guide • with tabs and staples • with letterheads using low temperature dyes or thermography • that is multipart or carbonless • that is designed for inkjet printing If you use any of the types of paper listed above, they may damage your machine. This damage is not covered under any Brother warranty or service agreement. Envelopes 2 Most envelopes will be suitable for your machine. However, some envelopes may have feed and print-quality problems because of the way they have been made. A suitable envelope should have edges with straight, well-creased folds and the leading edge should not be thicker than two sheets of paper. The envelope should lie flat and not be of baggy or flimsy construction. You should buy quality envelopes from a supplier who understands that you will be using the envelopes in a laser machine. Envelopes can be fed from manual feed slot one at a time. We recommend that you print a test envelope to make sure the print results are what you want before you print or purchase a large quantity of envelopes. Check the following: „ Envelopes should have a lengthwise sealing flap. „ The sealing flaps should be folded crisply and correctly (irregularly cut or folded envelopes may cause paper jams). „ Envelopes should consist of two layers of paper in the area circled in figure below. 1 1 1 Feeding direction „ Envelope joints that are sealed by the manufacturer should be secure. „ We recommend that you do not print within 0.6 in. (15 mm) of the edges of envelopes. 16