HP LaserJet P2050 Service Manual - Page 214

Problem-solve diagrams, Repetitive image defect ruler

|

View all HP LaserJet P2050 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 214 highlights

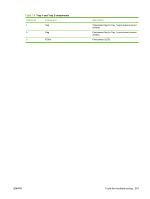

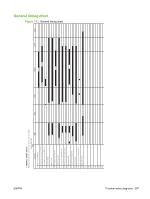

Problem-solve diagrams ● Repetitive image defect ruler ● Engine controller PCA ● Major components ● PCAs ● General timing chart ● Circuit diagram Repetitive image defect ruler Defects on product rollers can cause image defects to appear at regular intervals on the page, corresponding to the circumference of the roller that is causing the defect. Measure the distance between defects that recur on a page. Use the following table or the repetitive-defect ruler to determine which roller is causing the defect. To resolve the problem, try cleaning the roller first. If the roller remains dirty after cleaning or if it is damaged, replace the part that is indicated in Table 7-9 Repetitive defects on page 202. CAUTION: Do not use solvents or oils to clean rollers. Instead, rub the roller with lint-free paper. If dirt is difficult to remove, rub the roller with lint-free paper that has been dampened with water. NOTE: The following table replaces the graphical repetitive defect ruler. You can make your own ruler by using these measurements. For the most accurate results, use a metric ruler. Table 7-9 Repetitive defects Component Distance between defects Primary charging roller 38 mm (1.5 in) Transfer roller 39 mm (1.54 in) Developer roller 42 mm (1.65 in) Registration roller 43 mm (1.69 in) Fuser film 57 mm (2.24 in) Pressure roller 63 mm (2.48 in) Photosensitive drum 75 mm (2.95 in) 202 Chapter 7 Solve problems ENWW