HP 3390 Service Manual - Page 239

Media-handling problems, Print-media guidelines, Solving print-media problems - laserjet ink

|

View all HP 3390 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 239 highlights

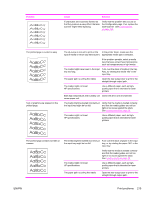

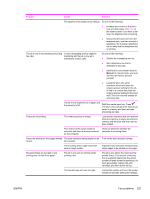

Media-handling problems Use the information in this section when the all-in-one experiences media-handling problems. Print-media guidelines ● For best results, make sure that the paper is of good quality, and free of cuts, nicks, tears, spots, loose particles, dust, wrinkles, voids, staples, and curled or bent edges. ● For best-quality printing, use a smooth type of paper. Generally, smoother media produces better results. ● If you are unsure what type of paper you are loading (such as bond or recycled), check the label on the package of paper. ● Do not use media that is designed for Inject printers only. Use media that is designed for LaserJet printers. ● Do not use letterhead paper that is printed with low-temperature inks, such as those used in some types of thermography. ● Do not use raised or embossed letterhead. ● The all-in-one uses heat and pressure to fuse toner to the paper. Make sure that any colored paper or preprinted forms use inks that are compatible with this fusing temperature (200°C or 392°F for 0.1 second). CAUTION Failure to follow these guidelines could cause jams or damage to the all-in-one. Solving print-media problems The following problems with media cause print-quality deviations, jamming, or even damage to the allin-one. Problem Poor print quality or toner adhesion Dropouts, jamming, or curl Excessive curl Jamming, damage to all-in-one Problems with feeding Cause Solution The paper is too moist, too rough, too heavy or too smooth, or it is embossed or from a faulty paper lot. Try another kind of paper, between 100 and 250 Sheffield, with 4 to 6% moisture content. The paper has been stored incorrectly. Store paper flat in its moisture-proof wrapping. The paper has variability from one side Turn the paper over. to the other. The paper is too moist, has the wrong grain direction, or is of short-grain construction The paper varies from side-to-side. The paper has cutouts or perforations. The paper has ragged edges. The paper varies from side-to-side. Open the rear output bin, or use longgrain paper. Turn the paper over. Use paper that is free of cutouts or perforations. Use high-quality paper that is made for laser printers. Turn the paper over. ENWW Print problems 217