Ricoh AC205 Service Manual - Page 158

FUSING ASSEMBLY, Thermostat, Hot Roller, Pressure Roller, Safety Features, Safety Devices

|

View all Ricoh AC205 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 158 highlights

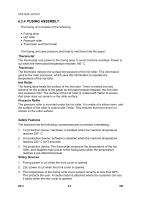

SYSTEM LAYOUT 6.2.4 FUSING ASSEMBLY The fusing unit consists of the following. • Fusing lamp • Hot roller • Pressure roller • Thermistor and thermostat The fusing unit uses pressure and heat to melt toner into the paper. Thermostat The thermostat cuts power to the fusing lamp to avoid machine overheat. Power is cut when the thermostat temperature reaches 160° C. Thermistor The thermistor detects the surface temperature of the hot roller. This information goes to the main processor, which uses this information to regulate the temperature of the hot roller. Hot Roller The fusing lamp heats the surface of the hot roller. Toner is melted into and remains on the surface of the paper as the paper passes between the hot roller and pressure roller. The surface of the hot roller is coated with Teflon to ensure that toner does not remain on the roller surface. Pressure Roller The pressure roller is mounted under the hot roller. It is made of a silicon resin, and the surface of the roller is coated with Teflon. This ensures that toner does not remain on the roller surface. Safety Features The machine has the following countermeasures to prevent overheating: 1. 1st protection device: Hardware is disabled when the machine temperature reaches 207° C. 2. 2nd protection device: Software is disabled when the machine temperature reaches 220° C for 3 seconds. 3. 3rd protection device: The thermostat measures the temperature of the hot roller, and disables main power to the fusing lamp when the temperature reaches a pre-determined level. Safety Devices 1. Fusing power is cut when the front cover is opened. 2. LSU power is cut when the front cover is opened. 3. The temperature of the fusing units cover surface remains at less than 80ºC. This protects the user. A caution label is attached where the customer can see it easily when the rear cover is opened. B273 6-4 SM