Brother International HE-800B Instruction Manual - English - Page 100

Imperfect cutter function (imperfect material cutting), 11-19. Cutter does not return

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 100 highlights

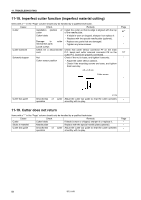

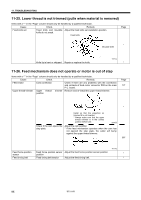

11. TROUBLESHOOTING 11-18. Imperfect cutter function (imperfect material cutting) Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Cutter Installation position of Install the cutter so that its edge is aligned with the top cutter of the needle plate. Cutter blade ・ If blade is worn or chipped, sharpen it or replace it. ・ Replace with the special needle plate (optional). Damage to mechanism parts Loose screws cutter ・Replace any parts that are damaged. ・Tighten any loose screws. Cutter solenoid Check for a disconnected Check that cutter sensor connector P7 on the main cord. P.C. board and cutter solenoid connector P2 on the cutter P.C. board are properly connected. Solenoid stopper Nut Check if the nut is loose, and tighten it securely. Cutter sensor position ・Adjust the cutter sensor position. ・Check if the mounting screws are loose, and tighten them securely. 4.5 ± 0.5 mm Cutter sensor Page 67* * * 10* * * Cutter bar guide 4017Q Smoothness of cutter Adjust the cutter bar guide so that the cutter operates operation smoothly with no play. * 11-19. Cutter does not return Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Cutter Cutter blade If blade is worn or chipped, sharpen it or replace it. Sticks in material Needle plate Replace with the special needle plate (optional). Cutter bar guide Smoothness of cutter Adjust the cutter bar guide so that the cutter operates operation smoothly with no play. Page * * * 91 HE-800B