Brother International HE-800B Instruction Manual - English - Page 99

Needle breakage, not strike the needle.

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 99 highlights

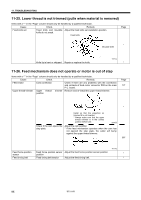

11. TROUBLESHOOTING Cause Upper thread trimmer lever Check Upper thread trimmer lever operating force Remedy Adjust so that the upper thread trimmer lever opens gently when the stop plate is separated from the stopper. Page * 4013Q 11-17. Needle breakage Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Needle Needle installation As viewed from the direction of the face plate, attach the needle so that the groove of the needle faces frontward. Rotary hook Needle bar height and needle bar lift amount (The gauge is an option part.) 1. Adjust the needle bar height to "1" on the gauge. 2. Adjust the needle and rotary hook timing to "2" on the gauge. Gap between the needle and the tip of the rotary hook Adjust the gap between the needle and the rotary hook tip to 0.01 - 0.08 mm. (Adjust to as large as possible without causing skipped stitches to occur.) * Move the needle bar to the left and right with your finger, and check that the tip of the rotary hook does not strike the needle. Needle plate Needle plate position Adjust the forward/back position of the needle plate so that the needle is in the center of the needle hole. Page 21 64* 65* 66* * Bisect 4014Q Burr on the screw hole Polish with buff. edge (in event of uneven material feeding) Check the chamfered side finishing * (Needle plate cross section) 4015Q Upper thread trimmer assembly Cutter Needle strikes upper thread trimmer Clearance between needle bar and cutter Refer to "11-16. Needle strikes upper thread trimmer". Install the cutter so that the clearance between the needle bar and the cutter is 0.3 mm. * The cutter release section of the needle bar should be at a right angle to the cutter. 89, 90* 0.3 mm 67* HE-800B 4016Q 90