Brother International HE-800B Instruction Manual - English - Page 71

Draining the oil, 8-3. Cleaning the control box air inlet port

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 71 highlights

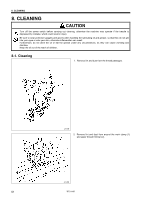

8-2. Draining the oil Bed base 8. CLEANING 3. Remove the bobbin case, and remove dust and lint from around the shuttle and fixed knife. Also wipe the bobbin to remove oil. * Periodically clean around the bobbin thread trimmer underneath the needle plate to remove any dust and thread scraps. If you continue using the sewing machine while dust or thread scraps have built up, it may cause the work clamp lifter pulse motor to go out of step. 2159Q 1. Gently tilt back the machine head. 2. Place the oil tank (1) against the underside of the table, and then remove the screw (2). 3. After the lubricating oil has been drained, make sure that the O-ring (3) is in the correct position, and then tighten the screw (2). * Wipe the magnet (4) and the bed base (5) so that they are free from dirt. 4070M 8-3. Cleaning the control box air inlet port Use a vacuum cleaner to clean the filter in the air inlet port (2) of the control box (1) at least once a month. 4875M HE-800B 62