Brother International HE-800B Instruction Manual - English - Page 103

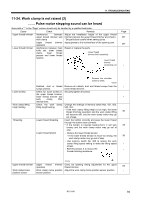

Work clamp is not raised (2)…… Pulse motor stepping sound can be heard

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 103 highlights

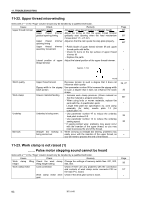

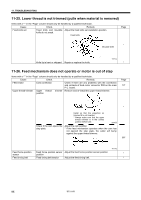

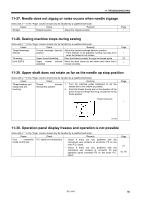

11. TROUBLESHOOTING 11-24. Work clamp is not raised (2) ...... Pulse motor stepping sound can be heard Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Upper thread trimmer Interference between Adjust the installation height of the upper thread upper thread trimmer and trimmer (remove the upper thread trimmer and check). work clamp * Be particularly careful when sewing joints. Upper thread trimmer Apply grease to the inclined face of the opening cam. operation Lower thread trimmer Interference between fixed knife set, lower thread clamp, lower thread presser and lower thread retainer. Repair or replace the parts. Lower thread trimmer link A assembly Lower thread trimmer connecting rod Page 68* 69* * Loose screws Work clamp lifting height setting Threading Remove the shoulder screw to check. 4022Q Rubbish, dust or thread Remove all rubbish, dust and thread scraps from the scraps present lower thread trimmer. * Check for loose screws in Securely tighten all screws. the upper thread trimmer, lower thread trimmer and * work clamp lifter mechanisms. Check the work clamp Change the settings of memory switch Nos. 001, 002, lifting height setting. 003, 004. * If the work clamp lifting height is too high, the lower thread trimming operation and the work clamp lifting 56 will become stiff, and the work clamp motor may go out of step. Lower thread threading Insert the bobbin correctly and pass the lower thread through the bobbin case correctly. * If the bobbin is inserted back-to-front, it will spin 25 loosely and the work clamp motor may go out of step. Lower thread tension ・ Reduce the lower thread tension. * If the lower thread tension is much too strong, the 26 work clamp motor may go out of step. ・ Use memory switch No. 060 to reduce the work clamp lifting speed setting to make the lifting speed * slower. ・ Buff this section A to reduce the thread retaining resistance. * 4023Q A Upper thread trimmer Upper thread trimmer Carry out opening timing adjustment for the upper operation thread trimmer. 69 Work clamp home position sensor Work clamp home position Adjust the work clamp home position sensor position. sensor position * HE-800B 94