Brother International HE-800B Instruction Manual - English - Page 51

Rear tack vector shape programs, USING THE SEWING MACHINE OPERATION PANEL: BASIC OPERATION

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 51 highlights

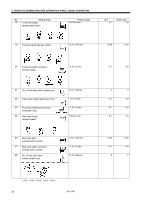

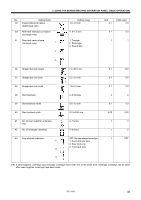

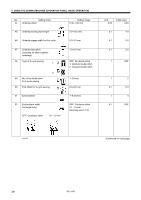

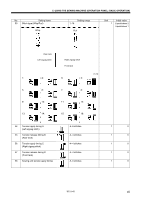

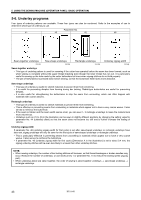

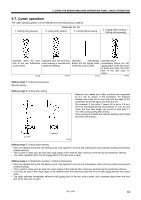

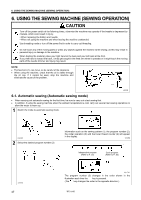

5. USING THE SEWING MACHINE (OPERATION PANEL: BASIC OPERATION) Symptom Parameter number 02 (Length of the hole) does not become larger. Cause If the sewing area is 32.0 mm and parameter number 05 (Cutter Y space) is set to 1.0 mm, parameter number 18 (Front tack length) is set to 1.0 mm and parameter number 25 (Rear tack length) is set to 1.0 mm, the length of the hole will be 32.0 - 1.0 - 1.0 - 1.0 1.0 = 28.0 mm. (The default setting is 27.8 mm to match the positions of the needle and cutter.) Parameter number 05 See illustration. (Cutter Y space) does not become larger. Parameter number 18 (Front tack length) and parameter number 25 (Rear tack length) do not become larger. See illustration. 4804M 5-5. Rear tack vector shape programs 1: Triangle Parameter No. 31 2: Rectangle 3: Saw-shape 4805M 4806M 4807M Setting range 1: Triangle General sewing Setting range 2: Rectangle ▪ This is effective for preventing the material from getting stuck in the needle hole when sewing the rear tack, which can happen when using lightweight materials. (An offset is used so that the stitches do not overlap when sewing the reverse zigzagging for the rear tack.) ▪ Reducing the number of front tack stitches is effective in preventing the material getting stuck at the front tack. ▪ Using a needle plate with a small needle hole (1.2 mm) as well can also help in preventing the material from getting stuck. Setting range 3: Saw-shape This is effective for preventing dimples in the rear tack, without the need for underlay sewing. HE-800B 42