Brother International HE-800B Instruction Manual - English - Page 87

Skipped stitches, Use the HE-800B bobbin case.

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 87 highlights

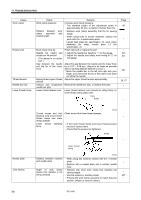

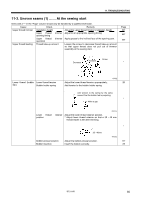

Cause Rotary hook 11. TROUBLESHOOTING Check Needle bar height and needle bar lift amount (The gauge is an option part.) Gap between the needle and the tip of the rotary hook Rotary hook lubrication Remedy 1. Adjust the needle bar height to "1" on the gauge. 2. Adjust the needle and rotary hook timing to "2" on the gauge. Adjust the gap between the needle and the rotary hook tip to 0.01 - 0.08 mm. (Adjust to as large as possible without causing skipped stitches to occur.) * Move the needle bar to the left and right with your finger, and check that the tip of the rotary hook does not strike the needle. ・Too small quantity of lubrication oil will cause thread breakage. Adjust the quantity of lubrication oil. ・The lubrication holes (1) between rotary hook and rotary hook joint do not match up. Page 64* 65* 66* 16* * 4894M Thread twisted around Remove any twisted thread from the inner and rotary rotary hook hook. 62 Upper thread amount Arm thread guide position Adjust the arm thread guide position. 28 Bobbin case Damaged outside of Polish with buff or replace the part. bobbin case and bent * Use the HE-800B bobbin case. * bobbin holder spring, etc. 11-2. Skipped stitches Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Page Needle Needle facing As viewed from the direction of the face plate, attach needle so that the groove of the needle faces 21 frontward. Needle installation height Insert the end of the needle shank so that it touches the top edge of the needle hole of the needle bar. 21 Bent needle Replace needle. 21 Blunt needle tip or burr Replace needle. 21 Thin needle Use a needle with a count that matches the thread and material. - Thread take-up spring Thread take-up spring Loosen the thread take-up spring tension or lower the tension and height height to such a degree that does not cause double 28 hooking. Adjust it while checking bar tacking stitches. (Continued on next page) HE-800B 78