Brother International HE-800B Instruction Manual - English - Page 105

Needle does not zigzag or noise occurs when needle zigzags

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 105 highlights

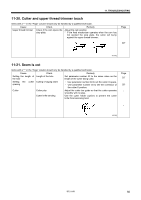

11. TROUBLESHOOTING 11-27. Needle does not zigzag or noise occurs when needle zigzags Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Stopper Stopper position Adjust the stopper position. Page * 11-28. Sewing machine stops during sewing Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Thread breakage detector Thread breakage detector Adjust the thread breakage detector position. position * If the detector is not adjusted, sewing may stop even when the thread is not broken. Threading Upper thread threading Pass the thread correctly through the thread guide. Error [E301] Upper thread trimmer Move the work clamp up and down and check that it operation moves smoothly. Page * 22 * 11-29. Upper shaft does not rotate as far as the needle up stop position Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Thread retainer and rotary hook are touching. Thread trimmer 1. Turn the machine pulley backward to set the mechanism position needle bar to the needle up position. 2. Push the thread driving arm in the direction of the arrow to set the thread trimming mechanism to the home position. Page Thread driving arm * 4109M 11-30. Operation panel display freezes and operation is not possible Items with a "*" in the "Page" column should only be handled by a qualified technician. Cause Check Remedy Poor connection P.C. board cord connections ・ Check if there are any problems with the inside control box. connection and contacts of connector P5 on the main P.C. board. ・ Check if there are any problems with the connection and contacts of connector P2 and operation panel connector P3 on the motor P.C. board. Page 74* 10, 74* HE-800B 96