Brother International HE-800B Instruction Manual - English - Page 9

Cleaning, Standard Adjustments, Table Of Error Codes, Troubleshooting, 17. Needle Breakage

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

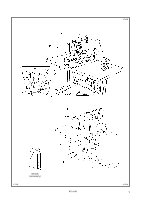

8. CLEANING 61 8-1. Cleaning 61 8-2. Draining the oil 62 8-3. Cleaning the control box air inlet port 62 8-4. Cleaning the eye guard 63 8-5. Checking the needle 63 8-6. Cleaning the length feed plate 63 9. STANDARD ADJUSTMENTS 64 9-1. Adjusting the needle bar height 64 9-2. Adjusting the needle and hook timing 65 9-3. Adjusting the clearance between needle and hook tip 66 9-4. Adjusting the inner rotary hook and rotary hook holder overlap 66 9-5. Adjusting the work clamp pressure 66 9-6. Adjusting the cutter installation 67 9-7. Adjusting the installation height of the upper thread trimmer 68 9-8. Adjusting the upper thread trimmer opening timing 69 9-9. Adjusting the lower thread clamp timing......... 70 9-10. Adjusting the bobbin presser 70 10. TABLE OF ERROR CODES 71 11. TROUBLESHOOTING 77 11-1. Upper thread breakage 77 11-2. Skipped stitches 78 11-3. Uneven seams (1) ...... At the sewing start 80 11-4. Uneven seams (2) ...... Lower thread is lifted up at the sewing start 81 11-5. Uneven seams (3) ...... Seam lifts up at the sewing start 81 11-6. Uneven seams (4) ...... Uneven sewing pitch at the sewing start... 82 11-7. Uneven seams (5) ...... Poor rounding of seam 82 11-8. Uneven seams (6) ...... Around rear tack or front tack 82 11-9. Uneven seams (7) ...... Loose thread end at end backtack 82 11-10. Uneven seams (8) ...... Thread sticking out at end backtack ........83 11-11. Uneven seams (9) ...... Sticking in needle plate 83 11-12. Uneven seams (10) ...... All stitches 84 11-13. Upper thread run out 85 11-14. Unraveling of thread trimmed by upper thread trimmer assembly 87 11-15. Upper thread miss-trimming 88 11-16. Needle strikes upper thread trimmer ..........89 11-17. Needle breakage 90 11-18. Imperfect cutter function (imperfect material cutting 91 11-19. Cutter does not return 91 11-20. Cutter and upper thread trimmer touch.......92 11-21. Seam is cut 92 11-22. Upper thread miss-winding 93 11-23. Work clamp is not raised (1) ...... Pulse motor stepping sound cannot be heard 93 11-24. Work clamp is not raised (2) ...... Pulse motor stepping sound can be heard 94 11-25. Lower thread is not trimmed (pulls when material is removed 95 11-26. Feed mechanism does not operate or motor is out of step 95 11-27. Needle does not zigzag or noise occurs when needle zigzags 96 11-28. Sewing machine stops during sewing.........96 11-29. Upper shaft does not rotate as far as the needle up stop position 96 11-30. Operation panel display freezes and operation is not possible 96 HE-800B