Stihl MS 162 Instruction Manual - Page 39

Inspection and Maintenance

|

View all Stihl MS 162 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 39 highlights

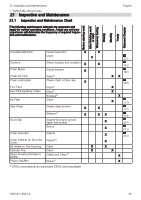

21 Inspection and Maintenance ► Tighten the shroud locks. 21 Inspection and Maintenance 21.1 Inspection and Maintenance Chart The following maintenance intervals are examples and apply for normal operating conditions. Actual use and your experience will determine the frequency of required inspec‐ tion and maintenance. English Before starting work After finishing work or daily Whenever fueling Weekly Monthly Yearly Relevant Chapter Complete Machine Visual inspection X X Clean X 20.1 Controls Check function and condition X X 16.2 Chain Brake Check function X 16.1 Chain Oil Tank Clean1) XX Chain Lubrication Check chain oil flow rate X 16.3 Fuel Tank Clean1) X Fuel Pick-Up Body / Filter Clean1) X Replace1) X Air Filter Clean X 20.3 Saw Chain Check chain tension X X 10.3 Sharpen1) X XX 21.5 Guide Bar Inspect for proper groove depth and spread X 21.4 Deburr X 21.4 Chain Sprocket Inspect X 21.3 Chain Catcher on Sprocket Inspect1) Cover X Air intake on Fan Housing Clean X X Cylinder Fins Clean X X Spark Arresting Screen in Muffler Check and Clean1) X Plugs in Muffler Check1) X 1) STIHL recommends an authorized STIHL servicing dealer 0458-200-8621-A 39