Stihl MS 162 Instruction Manual - Page 43

Troubleshooting Guide

|

View all Stihl MS 162 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

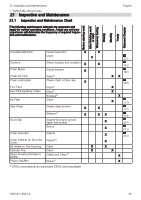

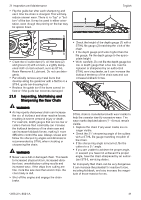

22 Troubleshooting Guide English A depth gauge that is too low will increase the kickback tendency of the chain saw and can increase kickback forces. A depth gauge that is too high will prevent the cutter from entering the workpiece and will lead to poor cutting performance. Always keep the required distance (a) between depth gauge and cutting edge, 23.5. To properly lower the depth gauge: 22 Troubleshooting Guide 22.1 Chain saw 0000-GXX-1220-A1 ► Lay the appropriate file gauge for the chain pitch on the chain and press it against the cut‐ ter to be checked. If the depth gauge pro‐ trudes past the file gauge, the depth gauge must be filed down. ► File the depth gauge so that it is flush with the top of the file gauge. ► Afterwards, remove the file gauge and file the leading edge of the depth gauge parallel to the service mark. When doing this, be careful not to further lower the highest point of the depth gauge. ► Lay the file gauge on the chain to check the height of the file gauge. The highest point of the depth gauge must be flush with the top of the file gauge. ► After sharpening, clean the chain thoroughly, removing any filings or grinding dust. ► Oil the chain thoroughly. Many performance issues can be resolved with a few simple steps. When troubleshooting, STIHL rec‐ ommends that you start with the following measures: ► Clean the air filter, 20.3. ► Clean or replace the spark plug, 20.4. ► Adjust the saw's idle speed, 22.2. ► If these measures do not resolve the issue, continue to the steps described below. Always shut off the engine before carrying out any inspection, cleaning or maintenance. Condition Possible Cause Remedy The engine does not There is insufficient fuel in the fuel start. tank. ► Refuel the chain saw, 13.2. The engine is flooded. ► Clear the combustion chamber, 22.3. The carburetor is iced up. ► Allow the engine to warm up gradu‐ ally to a temperature of about 50 °F (10 °C). The engine idles erratically. The carburetor is iced up. ► Allow the engine to warm up gradu‐ ally to a temperature of about 50 °F (10 °C). The engine stops while idling. The carburetor is iced up. ► Allow the engine to warm up gradu‐ ally to a temperature of about 50 °F (10 °C). Acceleration is poor. The chain is tensioned too tight. ► Properly tension the chain, 10.3. The engine does not The muffler is dirty. reach maximum speed. ► Have the muffler cleaned by an authorized STIHL servicing dealer. The chain does not The chain brake is engaged. rotate when throttle is opened. The chain is tensioned too tight. The guide bar sprocket is blocked. ► Disengage the chain brake, 12.2. ► Properly tension the chain, 10.3. ► Spray the guide bar sprocket with resin remover. 0458-200-8621-A 43