HP Color LaserJet 9500 Service Manual - Page 217

Table 28., 9000mfp

|

View all HP Color LaserJet 9500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 217 highlights

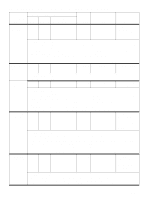

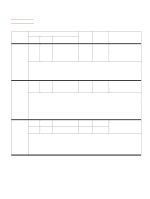

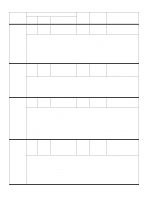

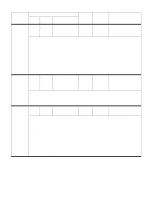

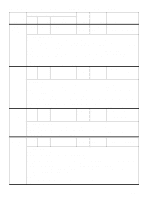

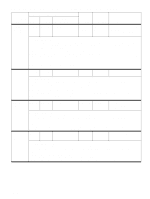

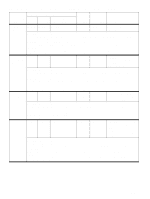

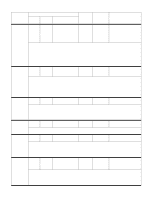

Table 28. Control panel and event log messages-3,000-sheet stapler/stacker (continued) Event log, if connected to Control panel message 9000 9500, 9500mfp, 9050, 9000mfp 9050/9040mfp User LED Service LED Description 13.12.30 Jam in left accessory 13.12.1E 13.12.1E 13.12.30 Amber blinking Yellow (4 blinks) A jam exists in the stapler. The carriage motor encoder detected that the carriage did not move to its home position. Recommended action: NOTE: This jam can occur if the carriage assembly motor is stopped. Whenever the carriage moves, a timeout sequence of 3.5 seconds begins. If, within this time, the carriage does not reach its target position (home position), the error code is triggered. 1 Print and analyze the event log to find out whether the error occurs repeatedly. 2 Make sure that the stapler is free of obstruction by moving it by hand from front to rear. 3 Make sure that the plastic wall from the accumulator is in place. If it is out-of-place, it will not allow the stapler to complete its routine. If it is out of place, attempt to snap the plastic wall back into position. If it is broken, then replace the accumulator assembly. 4 Replace the carriage assembly as needed. 5 Replace the controller PCA as needed. 13.12.31 Jam in left accessory 13.12.1F 13.12.1F 13.12.31 Amber blinking Yellow (4 blinks) A staple is jammed. Recommended action: 1 Remove the staple cartridge and verify there are staples pre-formed at the exit of the cartridge. 2 Make sure that no jammed staples are inside the cartridge. 3 Clear all of the pre-formed staples from the cartridge. 4 Reinstall the cartridge and verify that stapler operates correctly. 5 Test the stapler by sending a job to be stapled, in order to verify that the stapler completes its sequence. 6 Replace the staple cartridge as needed. 7 Replace the stapler unit as needed. 66.12.20 Output device failure 66.12.20 66.12.20 66.12.20 Amber solid Red (3 blinks) Either the retainer sensor or the retainer dc motor is damaged. Recommended action: 1 Analyze the event log for the frequency of the error message. 2 Turn the printer or MFP off and then on again to see whether the error is present during the power-on sequence. 3 Replace the accumulator module as needed. NOTE: When more than five errors in a row of this type are logged, it is an indication that the defective part is the retainer assembly, which is located in the accumulator module. 66.12.21 Output device failure 66.12.21 66.12.21 66.12.21 Amber solid Red (3 blinks) Either the bearing bracket or the gear wheel sensor is damaged. Recommended action: 1 Analyze the event log for the frequency of the error message. 2 Turn the printer or MFP off and then on again to see whether the error is present during the power-on sequence. 3 Replace the accumulator module as needed. NOTE: When more than five errors in a row of this type are logged, it is an indication that the defective part is the gear wheel or bearing bracket (or both), which are located in the accumulator assembly. ENWW Chapter 7 Troubleshooting 215