HP Color LaserJet 9500 Service Manual - Page 222

Table 29

|

View all HP Color LaserJet 9500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 222 highlights

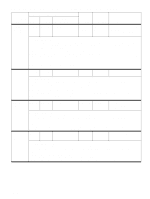

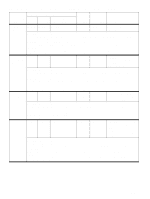

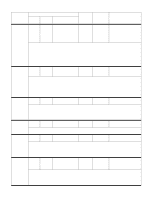

Table 29. Control panel and event log messages-3,000-sheet stacker (continued) Event log, if connected to Control panel message 9000 9500, 9500mfp, 9050, 9000mfp 9050/9040mfp User LED Service LED Description 13.12.13 Jam in left accessory 13.12.0D 13.12.0D 13.12.13 Amber blinking Yellow (2 blinks) Media jammed as it entered the accumulator. The PPEXIT or FLEXIT sensor is never deactivated. Recommended action: 1 Analyze the event log for frequency of the error message. 2 Make sure that the media is well-aligned in the input trays. 3 Make sure that the media is not wrinkled before arriving to the output device. 4 Make sure that the media is coming out in the accumulator well-centered. If this is not the case, then check the input trays to make sure that media is centered and not closer to either front or back. 5 Make sure that the media is not touching the plastic arms (wings) in the accumulator. 6 Make sure that customers are not blocking the exit of the accumulator when waiting for their print jobs. 7 Check for interference at the exit of the accumulator. NOTE: Paper with excessive curl can block the exit. 8 Make sure that the paper-stopper clips are in their correct position. 9 Make sure that the accumulator exit roller cover is installed correctly. 10 Replace the accumulator as needed. 13.12.40 Jam in left accessory 13.12.28 13.12.28 13.12.40 Amber blinking Yellow (5 blinks) Media is present in the offset module at power-on (the OMEXIT sensor is activated). Recommended action: NOTE: This error condition should not be present during normal operation. 1 Make sure that nothing in the offset module is activating the exit sensor. 2 Make sure that all of the sensor flags in the offset module move freely. 3 Replace the offset module as needed. 13.12.41 Jam in left accessory 13.12.29 13.12.29 13.12.41 Amber blinking Yellow (5 blinks) The offset module does not reach its home position. Recommended action: 1 Make sure that the offset module is free of obstruction. As a countermeasure, turn the offset feature off. 2 Make sure that all of the sensor flags in the offset module move freely. 3 Replace the offset module as needed. NOTE: When five errors in a row of this type are logged, it is an indication that the offset module has failed. 13.12.42 Jam in left accessory 13.12.2A 13.12.2A 13.12.42 Amber blinking Yellow (5 blinks) A jam exists in the offset module. The OMEXIT sensor is never deactivated. Recommended action: 1 Analyze the event log for frequency of the error message. 2 Make sure that the media is well-aligned in the input trays. 3 Make sure that the media is not wrinkled before arriving to the output device. 4 Make sure that the media is coming out in the offset module well-centered. If this is not the case, then check the input trays to make sure that paper is centered and not closer to either front or back. 5 Make sure that the media is not touching the plastic arms (wings) in the offset module. 6 Make sure that customers are not blocking the exit of the offset module when waiting for their print jobs. 7 Check for interference at the exit of the offset module. NOTE: Paper with excessive curl can block the exit. 8 Make sure that the paper-stopper clips are in their correct position. 9 Replace the offset module as needed. 10 Replace the paper path assembly as needed. 220 Troubleshooting ENWW