HP 2605dn HP Color LaserJet 2605/2605dn/2605dtn - Software Technical Reference - Page 302

Duplex Transfer, Toner offset - won t print

|

View all HP 2605dn manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 302 highlights

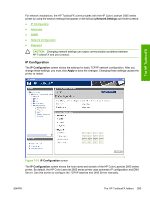

The HP ToolboxFX algorithm increases or decreases the current temperature target by some amount which depends on media type and other factors. The following settings are available for the Fuser control: ● Paper curl . This setting reduces fuser temperature. The instant-on fuser applies heat mostly on the image side. This causes asymmetric drying of the paper. When the paper reabsorbs moisture after printing, the difference between the front and back surfaces causes curl (heavy toner coverage also causes curl). Decreasing the heating of the paper and toner will tend to reduce curl (watch out for "cold" offset). Paper curl is worst for lighter papers and in higher humidity. ● Heavy coverage. This setting increases fuser temperature. The user's first option should be to pick a heavier media type in the driver. The defect in this case will be "cold" toner offset in the fuser. In this case, the toner is not quite melted enough to stick to the paper, so large patches will stick to the fuser sleeve and then offset 55mm down the page. ● Toner offset. This setting decreases fuser temperature. The user's first option should be to pick a lighter media type in the driver. The defect in this case is "hot" toner offset in the fuser. In this case, the toner next to the fuser sleeve gets too hot and partially separates from the toner that sticks to the paper. Offset also occurs at a 55m pitch, but it looks more like faint ghosting. ● Less/More fusing (-2, -1, +1, +2). These settings provide two levels of decreased fuser temperature and two levels of increased fuser temperature in case the above adjustments aren't enough. They can be used to "hunt" for the best setting. ● Transfer. The transfer bias voltage control in the engine is a complex algorithm depending on print mode and toner cartridge and humidity. An "increase" or "decrease" in transfer bias means that the transfer control algorithm increases or decreases the transfer bias by some amount which depends on media type and other factors. The following settings are available for the Transfer control. The following settings are available for the Transfer control. ● Dry paper. This setting increases transfer bias. Some papers (notably Chinese papers) become highly resistive in dry environments. To get enough transfer current into the paper to have good transfer, the transfer bias voltage needs to be increased. The range of paper resistivity in low humidity is so wide that a single standard engine print mode cannot cover all the cases. ● Humid paper. This setting decreases transfer bias. All papers absorb water at higher humidity and become electrically less resistive. This results in transfer defects caused by too much transfer current. The engine has a humidity sensor and also checks the conductivity of the ETB in order to estimate the humidity of the media, but this can be inadequate in more extreme cases. ● Rough paper. This setting increases transfer current. Rough papers such as cotton bond papers have a large portion of their surface area spaced away from contact with the OPC drum by their surface texture. In this case, more transfer current is required. ● Less/More transfer (-2, -1, +1, +2). These settings provide two levels of decreased transfer bias voltage and two levels of increased transfer bias voltage in case the above adjustments aren't enough. They can be used to "hunt" for the best setting. In extreme case (very dry or very wet), low transfer current defects and high transfer current defects can overlap; that is, there won't be a defect-free setting. These adjustments can help find the best operating point. ● Duplex Transfer. Paper which has just gone through the fuser before being printed on the duplex side is much drier and has higher resistivity than when the simplex side is printed. Therefore, the engine uses different transfer bias settings for the duplex side. It is common for the duplex side to 278 Chapter 7 The HP ToolboxFX ENWW