Ricoh FW780 Service Manual

Ricoh FW780 Manual

|

View all Ricoh FW780 manuals

Add to My Manuals

Save this manual to your list of manuals |

Ricoh FW780 manual content summary:

- Ricoh FW780 | Service Manual - Page 1

RICOH GROUP COMPANIES A163/A251/A252 B047/B048 SERVICE MANUAL 001317MIU - Ricoh FW780 | Service Manual - Page 2

- Ricoh FW780 | Service Manual - Page 3

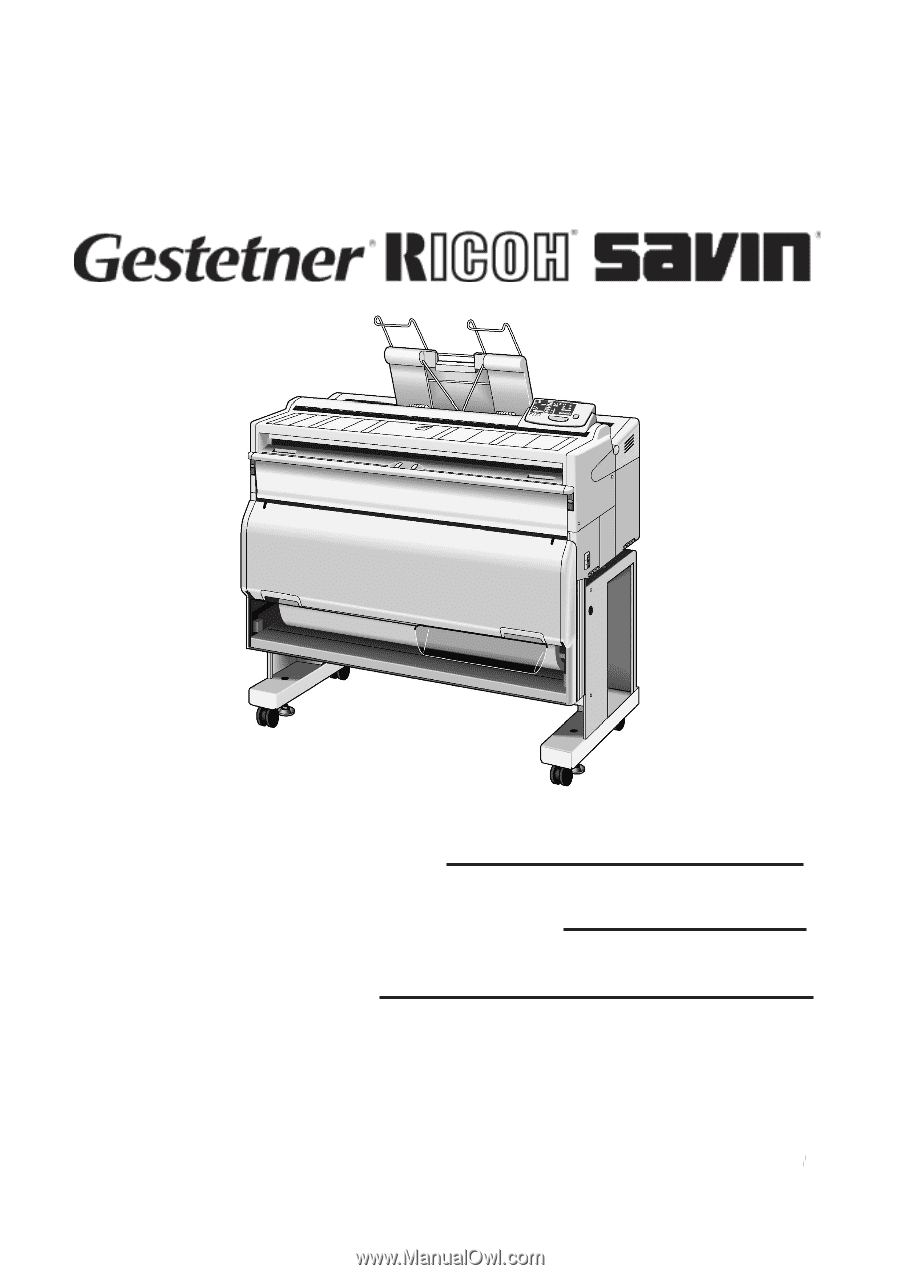

® ® RICOH GROUP COMPANIES A163/A251/A252/B047/B048 SERVICE MANUAL - Ricoh FW780 | Service Manual - Page 4

- Ricoh FW780 | Service Manual - Page 5

A163 SERVICE MANUAL 001317MIU - Ricoh FW780 | Service Manual - Page 6

- Ricoh FW780 | Service Manual - Page 7

Corporation and its member companies. NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY FASHION AND DISTRIBUTED WITHOUT THE PRIOR PERMISSION OF RICOH CORPORATION. All product names, domain names or product illustrations, including desktop images, used in this document are trademarks, registered - Ricoh FW780 | Service Manual - Page 8

- Ricoh FW780 | Service Manual - Page 9

WARNING The Service Manual contains information regarding service techniques, procedures, processes and spare parts of office equipment distributed by Ricoh Corporation. Users of this manual should be either service trained or certified by successfully completing a Ricoh Technical Training Program. - Ricoh FW780 | Service Manual - Page 10

- Ricoh FW780 | Service Manual - Page 11

LEGEND PRODUCT CODE A163 A251 A252 B047 B048 GESTETNER N/A N/A N/A A040 A041 COMPANY RICOH FW740 FW750 FW760 FW770 FW780 SAVIN N/A N/A N/A 7700W 7800W DOCUMENTATION HISTORY REV. NO. * 1 2 3 4 DATE 5/95 5/96 6/98 8/2001 COMMENTS Original Printing Revised Pages Reprint A251/A252 Addition B047/ - Ricoh FW780 | Service Manual - Page 12

- Ricoh FW780 | Service Manual - Page 13

check has to be made with exterior covers off or open while the main switch is turned on, keep hands away from electrified or mechanically driven components. 5. The inside and the metal parts of the fusing unit become extremely hot while the copier is operating. Be careful to avoid touching - Ricoh FW780 | Service Manual - Page 14

Do not incinerate the toner cartridge or the used toner. Toner dust may ignite suddenly when exposed to open flame. 2. Dispose of used toner, developer, and organic photoconductors according to local regulations. (These are non-toxic supplies.) 3. Dispose of replaced parts in accordance with local - Ricoh FW780 | Service Manual - Page 15

. 06/2004 OVERALL MACHINE INFORMATION 1. SPECIFICATIONS 1-1 2. PAPER PATH 1-3 3. DRUM PROCESSES 1-4 4. MECHANICAL COMPONENT LAYOUT 1-6 5. DRIVE LAYOUT 1-7 6. ELECTRICAL COMPONENT LAYOUT 1-8 DETAILED SECTION DESCRIPTIONS 1. DRUM 2-1 1.1 DRUM CHARACTERISTICS 2-1 1.2 DRUM DRIVE 2-2 2. CHARGE - Ricoh FW780 | Service Manual - Page 16

Rev. 06/2004 4.4.2 Recovery From Toner (Near) End condition 2-17 4.4.3 Toner Density Sensor 2-18 4.5 DEVELOPMENT BIAS 2-19 4.5.1 Basic Concept 2-19 4.5.2 Manual Image Density Bias 2-19 4.6 TONER SUPPLY 2-20 5. IMAGE TRANSFER AND PAPER SEPARATION 2-21 5.1 PRE-TRANSFER LAMP (PTL 2-21 5.2 IMAGE - Ricoh FW780 | Service Manual - Page 17

4.2 JAM CODE TABLE 4-31 5. SPECIAL TOOLS AND LUBRICANTS 4-33 6. SERVICE REMARKS 4-34 6.1 DRUM UNIT 4-34 6.1.1 Drum 4-34 6.2 CHARGE CORONA 4-35 6.3 OPTICS 4-36 6.4 DEVELOPMENT 4-36 6.5 TRANSFER AND SEPARATION 4-37 6.6 CLEANING UNIT 4-37 6.7 FUSING UNIT 4-38 6.7A PRESSURE ROLLER EVALUATION - Ricoh FW780 | Service Manual - Page 18

TONER DENSITY SENSOR REPLACEMENT 5-9 3.4 PTL REPLACEMENT 5-10 3.5 DEVELOPMENT BIAS VOLTAGE ADJUSTMENT 5-11 3.5.1 Bias Voltage for Image Area 5-11 3.5.2 Bias Voltage for Non-image Area 5-12 4. DRUM UNIT 5-13 4.1 DRUM UNIT REMOVAL 5-13 4.2 DRUM REPLACEMENT 5-14 4.3 CLEANING BLADE REPLACEMENT - Ricoh FW780 | Service Manual - Page 19

DRUM CURRENT ADJUSTMENT 5-20 4.8.1 Charge Current Adjustment 5-22 4.8.2 Transfer Current Adjustment 5-23 4.8.3 Separation Current Adjustment 5-24 5. FUSING 5-26 5.1 FUSING UNIT REMOVAL 5-26 5.2 HOT ROLLER REPLACEMENT 5-28 5.3 PRESSURE ROLLER REPLACEMENT 5-29 5.4 PRESSURE ROLLER THERMISTOR - Ricoh FW780 | Service Manual - Page 20

Roller Thermistor Open 6-8 2.4 SC Code E-4: Hot Roller Thermistor Short 6-8 2.5 SC Code E-5: Pressure Roller Thermistor Open 6-8 2.6 SC Code E-6: Pressure Roller Thermistor Short 6-9 2.7 SC Code E-7: Fusing Overheat 6-9 2.8 SC Code E-8: Fusing Warm-up Error 6-10 2.9 SC Code E-9: Toner Density - Ricoh FW780 | Service Manual - Page 21

Rev. 06/2004 7.1 EXTERIOR COVER REMOVAL 7-16 7.1.1 Front Cover Removal 7-16 7.1.2 Left and Right Cover 7-16 7.2 CUTTER UNIT REMOVAL 7-17 7.3 PAPER FEED ROLLER REPLACEMENT 7-18 7.4 PAPER FEED MOTOR TIMING BELT TENSION ADJUSTMENT 7-19 7.5 CUT LENGTH ADJUSTMENT 7-20 7.5.1 Preset Cut : Adjustment - Ricoh FW780 | Service Manual - Page 22

- Ricoh FW780 | Service Manual - Page 23

OVERALL MACHINE INFORMATION - Ricoh FW780 | Service Manual - Page 24

- Ricoh FW780 | Service Manual - Page 25

SPECIFICATIONS cartridge (6% original) Development Bias: Negative Toner Density Control: Direct toner density detection by induction sensor Image Density Adjustment: Development bias control + exposure control Paper Separation: Dual wire ac corona and pick-off pawls Cleaning: Cleaning blade - Ricoh FW780 | Service Manual - Page 26

Paper Feeding: Manual feed (roll feeder optional) Image Fusing: Heat and pressure type, teflon (upper) and silicone rubber (lower) rollers Fusing Lamp: Nichrome wire lamp (115 V: 1,100 W, 230 V: 1,100 W) Self-diagnostic Codes: 11 codes, displayed in copy counter Power Source: 115 V/60 Hz - Ricoh FW780 | Service Manual - Page 27

2. PAPER PATH A B C D E A: Original Path B: Paper from the manual feed C: Paper from the roller feed D: Paper exit E: Original Path from Rear Feeder A163 1-3 SM - Ricoh FW780 | Service Manual - Page 28

in the dark. 2. Exposure High intensity light from a fluorescent lamp is reflected from the moving original through the fiber optic array. The charge on the drum surface is dissipated in direct proportion to the intensity of the reflected light, thus producing an electric latent image on the - Ricoh FW780 | Service Manual - Page 29

between the paper and the drum. Then, the stiffness of the copy paper causes it to separate from the drum. The pick-off pawls help to separate paper which has low stiffness. 7. Cleaning The cleaning blade, which is angled against drum rotation (counter blade system), removes any toner remaining on - Ricoh FW780 | Service Manual - Page 30

Press Rollers 3. Copy Tray 4. Exit Rollers 5. Fusing Exit Rollers 6. Hot Roller 7. Pressure Roller 8. Gas Spring 9. OPC Drum 10. T/S Corona Unit 11. Main Drive Unit 12. Table 13. Paper Spool SM 14. Roll Feeder 15. Paper Registration Rollers 16. Development Unit 17. Toner Cartridge 18. Manual Feed - Ricoh FW780 | Service Manual - Page 31

10. Exit Unit Drive Belt 3. Development Unit 11. Hot Roller Drive Gear 4. Development Unit Relay Gear 12. Fusing Drive Sprocket/Gear 5. Development Drive Chain 13. Toner Collection Coil Drive Gear 6. Paper Registration Roller Clutch 14. Drum Drive Gear 7. Drum Drive Relay Gear 15. Original - Ricoh FW780 | Service Manual - Page 32

rollers. 30 Toner Supply Turns on to supply toner to the development unit. 31 Solenoids Pick-off Pawl Moves the pick-off pawls against the drum. 6 Switches Main Supplies power to the copier. 17 Original & Paper Cuts ac power when the original or paper feed Feed Safety unit is opened - Ricoh FW780 | Service Manual - Page 33

, charge grid, and development bias. 19 Transfer/ Separation Provides high voltage power for the transfer corona and separation. 16 Thermistors Hot Roller Monitors the hot roller's surface temperature. 8 Pressure Roller Monitors the pressure roller's surface temperature. 11 Thermofuses - Ricoh FW780 | Service Manual - Page 34

SM 1-10 A163 - Ricoh FW780 | Service Manual - Page 35

DETAILED SECTION DESCRIPTIONS - Ricoh FW780 | Service Manual - Page 36

- Ricoh FW780 | Service Manual - Page 37

to the intensity of the light. That is, where stronger light is directed to the photoconductor surface, a smaller voltage remains. The OPC drum used in this model has high sensitivity, good color reproduction, and good reproduction of low contrast originals (pencil originals, etc.) A163 2-1 SM - Ricoh FW780 | Service Manual - Page 38

tightened, the right flange presses firmly against the drum so that the drum is held tightly between the flanges. The drum and flanges turn together when the main motor is on. At this time, the drive is also transmitted to the original feed rollers [G] through the original feed drive pulley [H] and - Ricoh FW780 | Service Manual - Page 39

2. CHARGE 2.1 OVERVIEW [A] [B] Charge/ Grid Power Pack Charge Grid This model uses a single wire corona unit [A] to charge the OPC (organic photoconductor) drum [B]. The corona unit generates a corona of negative ions when a high negative voltage is applied to it by the charge/grid power pack. - Ricoh FW780 | Service Manual - Page 40

to --860 volts. This ensures that the charge does not fluctuate and an even charge is applied to the drum surface. The copy grid voltage and charge voltage amounts can be adjusted using SP # --11 and SP #--10 respectively. The grid drive signal applied to CN340-4 is a pulse width modulated signal - Ricoh FW780 | Service Manual - Page 41

VENTILATION [A] If ozone produced by the corona charge stays in the charge corona area, it may cause uneven corona charging to the drum. To prevent this, ozone is vacuumed out through the exhaust fan [A], and changed to oxygen by the ozone filter before being blown out of the copier. A163 2-5 SM - Ricoh FW780 | Service Manual - Page 42

exposure lamp [A] reflects off the original and through the fiber optics [B] to the OPC drum [C]. During exposure, the original moves across the exposure glass at the same speed as the drum's peripheral velocity. The platen plate [D] presses the original [E] flat against the exposure glass [F] just - Ricoh FW780 | Service Manual - Page 43

sensor [A] of the manual feed table detects the leading edge of the copy paper, the main motor starts rotating and the drum process (exposure lamp, the copy paper. The copy paper is fed past reg roller registration roller [C] and stops to wait for the original. "Set Paper", "RF Select" turns off - Ricoh FW780 | Service Manual - Page 44

turns off. At the appropriate time, the copy paper starts to be fed again. The original passes between the platen plate [D] and exposure glass [E] and from there to the 2nd original feed roller paper exits, the image creation process (drum process) stops. When both the original and copy paper have - Ricoh FW780 | Service Manual - Page 45

3.2.2 Original Jam Check Timing [A] There is only one sensor (original registration sensor) in the original path. Therefore, original jam cannot be detected during the time that a maximum original length (2m) passes this sensor. The original jam check is done after the leading edge of the original - Ricoh FW780 | Service Manual - Page 46

[A] [B] [C] The original feed rollers are driven through the original feed drive pulley and belt by the main motor as mentioned in the drum drive section. The paper registration rollers [A] are rotated by the main motor [B] through the gears [C] and the paper registration clutch [D]. SM 2-10 A163 - Ricoh FW780 | Service Manual - Page 47

a duty ratio of 15% to 100%. The basic light intensity level is determined by the image density selected at the operation panel (manual ID control). The CPU uses the light sensor to monitor the actual light intensity. The light sensor [C] directly detects the lamp's light output and feeds a light - Ricoh FW780 | Service Manual - Page 48

93 2.13 2.33 2.52 2.72 3.4.1 Manual ID Control The user can select one of 14 manual ID levels. For each level, the intensity of the light output by the exposure lamp (as measured by the light sensor) varies. This is shown in the above table. The development roller bias also varies. (See the section - Ricoh FW780 | Service Manual - Page 49

The turning sleeve of the development roller then carries the developer past the doctor blade [C]. The doctor blade trims the developer to the desired thickness and creates backspill to the cross-mixing mechanism. The development roller continues to turn, carrying the developer to the OPC drum. When - Ricoh FW780 | Service Manual - Page 50

[D] [C] [B] [A] [H] [G] [F] [I] [E] When the main motor [A] is on, the paddle roller [B], development roller [C], and mixing auger [D] in the development unit are driven through the development drive chain [E] and gears [F]. The toner agitator shaft [G] is rotated through the gears [H] by the - Ricoh FW780 | Service Manual - Page 51

within the machine. The developer that is attracted to the development roller [A] is split into two parts by the doctor blade [B]. One part (the magnetic brush) goes on to develop the latent image on the drum. However, the other part is trimmed off by the doctor blade and directed to the backspill - Ricoh FW780 | Service Manual - Page 52

Supply Ratio) 0: No supply 1: 7.5% 2: 15% 3: 30% 4: 50% 5: 100% The toner density sensor is used for toner density control. It measures the ratio of toner to carrier in the developer. Toner is supplied every 600 mm when the toner density sensor value (VTS) meets one of the TS level conditions from - Ricoh FW780 | Service Manual - Page 53

(near) end is not detected until 30 meters (A1/D size: 50 copies) after replacing toner cartridge. The same action as described above will also take place after opening and closing original feed unit, or turning the main switch off and on, or unplugging and plugging power cord. This is known as - Ricoh FW780 | Service Manual - Page 54

through the transformer to change. As the amount of toner in the developer increases, the effect of the carrier particles decreases and the voltage applied to CN104-A10 decreases. Conversely, when the toner concentration drops as toner is used up, the effect of the carrier on the sensor coils - Ricoh FW780 | Service Manual - Page 55

drum. This leaves a negative charge pattern corresponding to the dark areas of the original. After exposure, however, a small residual charge of about --100 volts (for white paper) remains in the exposed areas. This residual charge could attract positively charged toner from the development roller - Ricoh FW780 | Service Manual - Page 56

diameter) in a plastic strip [C] along one side of the toner cartridge. The toner particles thus ejected from the cartridge fall into the development unit and are mixed into the developer. The toner agitator turns at 75 rpm and the toner supply rate is approximately 22.5 grams per minute. SM 2-20 - Ricoh FW780 | Service Manual - Page 57

drum surface. This prevents toner particles from being re-attracted to the negatively charged drum during the paper separation process. It also makes image transfer and paper separation easier. 5.2 IMAGE TRANSFER The registration rollers [B] feed the copy paper through the transfer entrance guides - Ricoh FW780 | Service Manual - Page 58

. The pick-off shaft [B] then rotates clockwise and the pick-off pawls [C] touch the drum surface. Just after the leading edge of the copy paper passes the pick-off pawls, the pick-off solenoid turns off again. The pick-off spring [D] then rotates the pick-off shaft counterclockwise and moves the - Ricoh FW780 | Service Manual - Page 59

approximately --5.0 kV to the transfer corona wire. The main board turns on the separation corona using PWM signals (S.AC Drive and S.DC Drive). The dc/dc or low mode, thin copying paper (translucent paper or film) may be wrapped around the drum. This may cause the paper to be jammed or transported - Ricoh FW780 | Service Manual - Page 60

copier uses the counter blade system for drum cleaning. The blade [A] is angled against the drum rotation. This counter blade system has the advantage of high cleaning efficiency. The cleaning blade removes any toner remaining on the drum after the image is transferred to the copy paper. The toner - Ricoh FW780 | Service Manual - Page 61

the gears [C], moves used toner from the cleaning unit to the toner collection bottle [D]. The toner collection bottle capacity is enough to hold used toner from making 1220 m copies. The CPU uses the copy quantity to detect the used toner overflow. The used toner overflow condition is detected - Ricoh FW780 | Service Manual - Page 62

Rev. 5/95 7. QUENCHING [B] [A] After the drum [A] is cleaned by the cleaning blade, light from the quenching lamp [B] neutralizes any charge remaining on the drum. The quenching lamp turns on and off at the same time as the main motor. The main board turns on the quenching lamp LEDs by dropping - Ricoh FW780 | Service Manual - Page 63

copy paper by applying heat and pressure. The hot roller [C] is made of carbon-teflon and the pressure roller [D] is made of silicone rubber. Pressure is constantly applied by the pressure levers at the ends of the fusing unit. The fusing lamp [E], which is located at the hot roller axis, turns on - Ricoh FW780 | Service Manual - Page 64

DRIVE MECHANISM 8.2.1 Fusing Unit Drive [I] [J] [A] [J] [C] [B] [H] [G] [D] [F] [E] The hot roller [A] is turned by the hot roller drive gear [B] as shown. The pressure roller [C] is friction driven by the hot roller. The fusing rollers turn constantly when the main motor [D] is on, driven - Ricoh FW780 | Service Manual - Page 65

the triac to complete the lamp circuit, thus turning on the lamp. RA201 guards against a failure of the +24 volt power supply. When +24 volts is applied at CN202-1 and CN106-B15 drops to LOW, RA201 is energized and its ac contacts stay open. If the +24 volts power from CN 106 - Ricoh FW780 | Service Manual - Page 66

main board turns off the fusing lamp if the temperature goes too high. The input from TH1 (Hot Roller Thermistor) turns off. The overheat protection circuit becomes effective at about 215°C. TF1 provides overheat protection in case a short bypasses the control and drive circuits. This fuse will open - Ricoh FW780 | Service Manual - Page 67

TEMPERATURE CONTROL Hot Roller Temp. (°C) Pressure Roller Temp. (°C) Operating Temperature Lower Limit Lower Limit The main board monitors the temperature of the hot roller through TH1 and the temperature of the pressure roller through TH2. The CPU determines whether or not to turn on the fusing - Ricoh FW780 | Service Manual - Page 68

SP #--8 adjusts the pressure roller temperature. SP #--7 shift the temperature in 1 degree increments (--9°C to +9°C). The fusing temperature can be monitored using SP #--9. - The ready condition - When the hot roller temperature reaches the ready temperature, the copier enters the ready condition - Ricoh FW780 | Service Manual - Page 69

is kept at 195°C and it starts to rotate to keep the pressure roller temperature between 130°C and 145°C. When the hot roller or pressure roller temperature is below the lower limit, copying is disabled. After fusing, paper shrinks slightly, and expands again after a few minutes. The shrinkage and - Ricoh FW780 | Service Manual - Page 70

copier is not in use, the energy saver function reduces the power consumption by decreasing the fusing temperature. When the Clear Modes/Stand-by key is hold down for over 2 seconds, the copier goes into the energy saver mode. A message is displayed on copy counter and all the other indicators turn - Ricoh FW780 | Service Manual - Page 71

8.6 FUSING ENTRANCE GUIDE HEIGHT [A] Paper creasing may occur depending on the type of paper used. The fusing entrance guide [A] height is changed by adjusting a lever (there are three settings). A163 2-35 SM - Ricoh FW780 | Service Manual - Page 72

the gap constant. To stop paper dropping from the roll cutting rail, the holders hold the slide shafts at the lower position by holding the paper against the cutter guide stay. The guide shaft [D], made of resin, protects the paper knife blade from damage by metal parts of the unit. SM 2-36 - Ricoh FW780 | Service Manual - Page 73

INSTALLATION - Ricoh FW780 | Service Manual - Page 74

- Ricoh FW780 | Service Manual - Page 75

80% RH 3. Ambient Illumination: 4. Ventilation: 5. Ambient Dust: Less than 1,500 Lux (do not expose to direct sunlight). Minimum space 20 m3 Room air should turn over at least 30 m3/hr/person. Less than 0.15 mg/m3 (4 x 10-3 oz/yd3) 6. If the installation place is air-conditioned or heated, place - Ricoh FW780 | Service Manual - Page 76

(24 in) 1.2 MACHINE LEVEL 1. Front to back: Within 5 mm (0.2") of level 2. Right to left: Within 5 mm (0.2") of level Make sure that the machine is level using a carpenter's level. A163 3-2 SM - Ricoh FW780 | Service Manual - Page 77

1.3 POWER SOURCE 1. Input Voltage Level: 115 V/60 Hz More than 15 A (for U.S.A. version) 220 V/230 V/240 V/50 Hz More than 7 A (for European version) 2. Permissible Voltage Fluctuation: ±10% 3. Do not set anything on the power cord. NOTE: a) Make sure the plug is firmly inserted in the outlet. - Ricoh FW780 | Service Manual - Page 78

1.4 INSTALLATION PROCEDURE Copier Check the accessories and their quantities according to the following list: Guide Wire 2 pcs Copy Tray 1 pc Copy Guide 1 pc A163 3-4 SM - Ricoh FW780 | Service Manual - Page 79

[E] [C] [A] 1. Lower the feet [A] so that the table does not move while the copier is being installed on the table. 2. Place the copier [B] on the table [C] (Place the copier feet [D] into the table holes [E]). Warning: The copier is not attached to the table. Pushing the copier too hard may cause - Ricoh FW780 | Service Manual - Page 80

[E] 3. Open the paper path section [A] and remove two strips of shipping tape [B]. 4. Remove the right upper cover [C] (2 screws). 5. Remove the drum protection sheet [D], and remove the screw [E] to apply cleaning blade pressure to the drum. Remove paper from transport section. Close the paper path - Ricoh FW780 | Service Manual - Page 81

[D] 6. Open the original feed unit [A], manual feed table [B], and toner supply cover [C]. Remove a sheet [D] covering the developer entrance. Pour 1 kg of the developer [E] into the development unit evenly across its width as shown, then close all doors. 7. Plug in the power supply cord and turn on - Ricoh FW780 | Service Manual - Page 82

Rev. 5/95 [D] [B] [A] [C] [E] NOTE: If the fusing temperature is lower than 60°C when the main switch is turned on, the main motor will rotate. In this case, it is not necessary to access the SP mode when loading the second Kg of developer (in step 11). Turn off the main switch to stop the main - Ricoh FW780 | Service Manual - Page 83

service indicators will blink (SP mode). 14. Select 36 using the + and - keys. Enter "1" by pressing the following keys. Function Select key [E] + key RF Select key [F] Five minutes later, the copier will automatically return to the normal operating mode from SP mode. (New developer initialization - Ricoh FW780 | Service Manual - Page 84

[A] [B] [C] 15. Install the toner cartridge [A] as shown. 16. Remove the sealing tape [B] from the cartridge and turn the knob [C] until it stops. A163 3-10 SM - Ricoh FW780 | Service Manual - Page 85

[A] [C] [B] 17. Attach the guide wires [A] to the copy tray [B]. 18. Install the copy tray [B] and copy guide [C]. 19. Reinstall all the covers. 20. Check the copy quality and copier operation. SM 3-11 A163 - Ricoh FW780 | Service Manual - Page 86

1.5 INSTALLATION PROCEDURE Table Check the accessories and their quantities according to the following list: Top Plate 1 Left Side Plate 1 Right Side Plate 1 Middle Plate 1 Rear Cover 1 Screws with Spring Washer - M4x8 14 A163 3-12 SM - Ricoh FW780 | Service Manual - Page 87

of the left plate. 1. Temporarily install the top plate [C], left [D], and right side plate [E] (6 screws). 2. Turn the table up-side down in the direction of A. 3. Install the middle plate [F] and rear cover [G] (4 screws each). 4. Tighten all the screws until the spring washers [H] of screws are - Ricoh FW780 | Service Manual - Page 88

and their quantities according to the following list: Cutter Guide 1 pc Cutter Knife 1 pc Roll Paper Arm 2 pcs Roll Paper Shaft 1 pc Roll Shaft Holder 2 pcs Roll Flange 2 pcs [A] [B] [A] [B] 1. Remove the small caps [A] from the lower front cover. 2. Attach the roll shaft holders [B] as shown - Ricoh FW780 | Service Manual - Page 89

[B]. (Install each arm pin [C] into each cutter guide hole [D]. Position the cutter guide pin [E] in the lower slot of the roll paper arm [F].) 4. Install the cutter guide on the roll shaft holder [G]. 5. Slide the roll paper shaft [H] into the roll paper. 6. Fit the roll flanges [I] onto the roll - Ricoh FW780 | Service Manual - Page 90

- Ricoh FW780 | Service Manual - Page 91

SERVICE TABLES - Ricoh FW780 | Service Manual - Page 92

- Ricoh FW780 | Service Manual - Page 93

1 Developer 2 Cartridge holder 3 Entrance seal 4 Development filter 2.1KM (3.6K) ( 4.3KM 6.4KM 8.6KM 10.8KM (7.2K) (10.8K) (14.4K) (18K) ) A1 sideways/D size Notes C C Alcohol Alcohol C C I C I C I Alcohol C C C C C Alcohol Clean with lens paper if necessary Clean using water - Ricoh FW780 | Service Manual - Page 94

used toner F. Paper Feed 1 Registration roller 2 Paper feed guide plate 3 Manual feed table C C C C C Water C C C C C Water C C C C C Water G. Fusing 1 Hot roller 2 Pressure roller 3 Thermistors 4 Hot roller strippers 5 Pressure roller stripper 6 Entrance guide plate 7 Exit turn - Ricoh FW780 | Service Manual - Page 95

(3.6K) ( 4.3KM 6.4KM 8.6KM (7.2K) (10.8K) (14.4K) ) A1 sideways/D size 10.8KM (18K) Notes Clean using suitable solvent if necessary Others 1 Chain 2 Gears 3 Ozone filter Lubricate with I I I I I G501 if necessary Lubricate with I I I I I G501 if necessary R R R R R F. Roll - Ricoh FW780 | Service Manual - Page 96

the first and second press rollers using alcohol. 1. Clean the reflection plate using alcohol. 2. Clean the exposure glass using water. 3. Clean the exposure lamp using water if necessary. 4. Clean the fiber optics array using lens paper if necessary. NOTE: After removing the drum, wrap it in clear - Ricoh FW780 | Service Manual - Page 97

. Replace the cleaning blade. 6. Development Unit (every 3.6K) 1. Clean the cartridge holder using a dry cloth if it is dirty. Development Unit (every 30K) 2. Clean the entrance seal using a dry cloth if it is dirty. Replace the developer. Development Unit Clean the development filter. (every - Ricoh FW780 | Service Manual - Page 98

1. Clean the registration roller using water. 2. Clean the paper feed guide plates using water. 3. Clean the manual table using water. Clean the small separation rollers using suitable solvent. 1. Clean the fusing thermistors using suitable solvent. 2. Clean the hot roller strippers using suitable - Ricoh FW780 | Service Manual - Page 99

2. SERVICE TABLES 2.1 TEST POINTS Main Board Number TP101 TP102 TP103 TP104 TP105 Function VAA (+24V) Vcc (+5V) GND Toner density sensor (CN104-A10) Light sensor output (CN104-B1) Charge/Bias/Grid Power Pack Number TP1 TP2 Function Development Bias Voltage Grid Voltage 2.2 VARIABLE RESISTORS - Ricoh FW780 | Service Manual - Page 100

3. SERVICE TOOLS 3.1 SERVICE PROGRAM MODE The service program (SP) mode is used to check electrical data, change mode or adjustment values. 3.1.1 Service Program Mode Access Procedure How to access the SP mode for service representatives (All service program modes can be accessed with this - Ricoh FW780 | Service Manual - Page 101

length indicator (the four digit indicator beside the mark). 3. The present setting is displayed in the paper length indicator. 4. Select the setting using the and key to enter the selected setting. 5. Leave the SP mode. keys, then press the How to read data 1. Access the SP mode and - Ricoh FW780 | Service Manual - Page 102

Service Program Mode Table 1: A "*" before the mode number means that the mode can be accessed by custormers or sales Manual Feed Start Selects the time to when the registration 0: 2 seconds Time Setting roller starts rotating after the entrance sensor 1: 0.7 second detects the paper - Ricoh FW780 | Service Manual - Page 103

Auto Off ⇒ 15 Auto off time can be selected 1 ~ 120 minutes (1 minute per step) Default: 30 minutes 16 Not Used to 19 Paper Length Count Up/Down *20 Setting Selects if the paper length is in count down or 0: Down up when the preset cut key is pressed. (Long → Short) 1: Up (Short → Long - Ricoh FW780 | Service Manual - Page 104

used as fixed paper size when the "Preset Cut" key is pressed. 33 Not Used to 34 All Indicators On *35 New Developer Initialization 36 37 Not Used Release Fusing 38 Unit Service Call 39 Not Used , the machine automatically returns adjust the toner to normal operating mode. sensor output, - Ricoh FW780 | Service Manual - Page 105

the translucent paper mode. 46 Adjustment (1100 mm, translucent Paper) Roll Feeder used for test) Used Toner Counter 52 Indicates the copy length after clearing the tF=XX,XXX used toner counter. This counter is (Beeper) automatically cleared if the clear mode key is pressed after turning - Ricoh FW780 | Service Manual - Page 106

to increase the 0: 1 minute Q/M of the developer. This warm-up is done 1: 2 minute if the fusing temperature is lower than 60°C 2: 3 minute when the main switch is turned on. 3: None Determines the maximum paper length. Note: If paper longer than 2000 mm is used, skew copy, poor fusing, crease - Ricoh FW780 | Service Manual - Page 107

supply 0: No is done while the "Emergency Stop" key is 1: Special Toner pressed. Toner sensor voltage is displayed Supply Mode on the "Paper Length" indicator. If the voltage is lower than 1V, toner is not supplied. 63 Not Used SP Mode Display Selects the indication speed on the display. Speed - Ricoh FW780 | Service Manual - Page 108

when the OPC drum is replaced. (SP #--1) Displays the total length [m] of copied paper after the new developer is poured. dE = XX,XXX This counter is automatically cleared when the new developer initialization is done. Displays the total length of copied paper [m] after a new toner cartridge is - Ricoh FW780 | Service Manual - Page 109

Displays the last five service calls one after E1 = XX (The last the other. error code) ↓ E2 = XX (1 before the last error code) ↓ E3 = XX (2 before the last error code) ↓ E4 = XX (3 before the last error code) ↓ E5 = XX (4 before the last error code) ↓ Beeper (XX= Error Code) SM 4-17 A163 - Ricoh FW780 | Service Manual - Page 110

inside the upper right cover. Please refer to page Used * Note: 1 This counter is not used for the toner density step control (described on page 2-16). * Note: 2 For the toner density step control, this counter counts down from 150 (m) to 0 (m) after the developer initialization. When the developer - Ricoh FW780 | Service Manual - Page 111

4: A1 length (594 mm) 5. Sheet (Any size) --3 Inch/mm Exchange Selects the unit in which the edge margin and 0: mm paper length is indicated by. 1: Inch --4 Not Used Registration --5 Adjustment Adjusts the paper registration. 0: Standard --9.9 ← 0 → 9.9 mm Advance Delay SM 4-19 A163 - Ricoh FW780 | Service Manual - Page 112

temperature is higher than 210°C (pressure roller temperature is higher than 180°C), "HHH" is indicated. Drum Charge Setting --10 Determines the drum charge voltage. In this mode, the charge corona can be turned on and off using the Copy Media key. Translucent paper = ON Translucent Film = OFF - Ricoh FW780 | Service Manual - Page 113

Bias Voltage for the Image Area Setting --20 Determines the development bias voltage for 3: Standard the image area. 0 ← 3 → 8 In this mode, the bias voltage can be turned Low High on and off using the Copy Media key. Translucent paper = ON Translucent Film = OFF Bias Voltage for Non-image - Ricoh FW780 | Service Manual - Page 114

← 80 → 120 when the new developer initialization (SP36) Low High is done. In this mode, PTL, main motor, QL and the bias voltage for non-image area can be turned on and off using the Copy Media key. Translucent paper = ON Translucent Film = OFF Displays the toner sensor output voltage for - Ricoh FW780 | Service Manual - Page 115

sensor output A = X,XX voltage. In this mode, the PTL, main motor, QL and A = Toner Sensor the bias voltage for non-image areas can be Voltage turned on and off using the Copy Media key. Translucent paper = ON During the stand-by Translucent Film = OFF condition, and copy Even if the SP - Ricoh FW780 | Service Manual - Page 116

full power. --62 Not Used --63 Factory Use Only Manual Feed Beeper sounds if a sheet is set on the --64 Attention Mode 1 manual feed table before the "Set Paper" indicator lights. 0: NO 1: Manual Feed Attention Mode 1 Manual Feed Beeper sounds when the manual table is --65 Attention Mode - Ricoh FW780 | Service Manual - Page 117

Fixed Paper Size Pattern Data (SP No.22) In mm Mode 0: 1189, 841, 594, 420, 297 1: 2000, 1189, 841, 594, 420, 297, 245 2: 2000, 1900, 1800, 1700, - Ricoh FW780 | Service Manual - Page 118

13: 80.0, 77.5, 75.0, 72.5, 70.0, 67.5, 65.0, 62.5, 60.0, 57.5, 55.0, 52.5, 50.0, 44.0, 34.0, 22.0, 17.0, 11.0, 9.6 14: 80.0, 78.0, 76.0, 74.0, 72.0, 70.0, 68.0, 66.0, 64.0, 62.0, 60.0, 58.0, 56.0, 54.0, 52.0, 50.0, 48.0, 46.0, 44.0, 42.0, 40.0, 38.0, 36.0, 34.0, 32.0, 30.0, 28.0, 26.0, 24.0, 22.0, - Ricoh FW780 | Service Manual - Page 119

pressed, hold it down for more than 3 indicators blink). How to leave the input/output check mode Press the following keys in sequence. → → or turn off the main switch. NOTE: Each of the above procedures must be finished within 20 seconds. How to select the program number The program number - Ricoh FW780 | Service Manual - Page 120

component is displayed on the paper length indicator ("ON" or "OFF" is displayed.). If a program number not used is selected, "NOT" is rotating.) --6 Door Switch (Status is "ON" when the door is open.) --7 to --9 Not Used --10 R/F Leading Edge Sensor --11 Roll Feeder Door Switch --12 Right - Ricoh FW780 | Service Manual - Page 121

paper length indicator. To turn off the component, press the key again. Program No. Electrical Component 0 Main Motor 1 Toner + Quenching Lamp 24 to 25 Not Used 26 Roll Feeder Dehumidity Heaters 27 Roll Feeder Cutter Motor*Note 28 Roller Feeder Paper Feed Motor NOTE: The cutter unit - Ricoh FW780 | Service Manual - Page 122

stop key down and indicators blink). 2. Input the operation panel setting that the customer requires (paper size, image density, etc.). 3. Turn off the main switch. The setting, just before the main switch is turned off, is memorized as the power on initial setting. It appears again when the main - Ricoh FW780 | Service Manual - Page 123

jam occurs, the cause of the jam is displayed by using the following jam code. 4.1 ACCESS PROCEDURE 1. When a document jam or paper jam occurs, press and hold the Clear/Stop key. 2. Read the jam code. 4.2 JAM CODE TABLE Code PJ01 PJ02 PJ03 PJ04 PJ05 PJ20 PJ21 PJ22 PJ23 PJ30 PJ31 PJ32 PJ40 PJ41 - Ricoh FW780 | Service Manual - Page 124

Code PJ90 PJ98 PJ99 Cause of Jam Roll feeder. motor does not turn off after paper is fed 500 mm more than the maximum paper length. SP Mode No. SP80 (Others) Registration sensor does not turn off after paper is fed 2500 mm. Original registration sensor does not turn off after paper is fed 2500 - Ricoh FW780 | Service Manual - Page 125

Deluxe Test Lead Accessory Kit 3 Grease -- Mobil Temp.78 4 Grease-G501 5 Current Measuring Drum 6 Test Chart OS-A1 (2 sheets/set) 7 Spring Hook 8 Setting Powder PART NO. 54209507 54209508 54479078 52039501 A0239520 A0239504 54199653 54429101 REMARKS BECKMAN RMS3030 BECKMAN DL241 400 g/can - Ricoh FW780 | Service Manual - Page 126

inserting or pulling the drum unit out of the copier to avoid exposing it to bright light or direct sunlight. This will protect the drum from light fatigue. 9. Before removing the drum, place a sheet of paper under the drum to catch any falling toner. 10. Dispose of used drums according to local - Ricoh FW780 | Service Manual - Page 127

section. Also, releasing only one side of the paper path section deform the copier machine, which may cause paper jam and copy image problem. Release both levers together while holding the paper path section to open the paper path section slowly. 16. The drum unit is heavy. Take care not to injure - Ricoh FW780 | Service Manual - Page 128

and installing it. 9. During the developer initialization, do not turn off the main switch, or do not open the original feed unit or the paper path section, or do not unplug the copier power cord. If these conditions happen, do the developer initialization again, the toner density sensor cannot be - Ricoh FW780 | Service Manual - Page 129

to damage the edge of the cleaning blade. 2. Dispose of used toner according to local regulations. 3. Do not press the cleaning blade too hard. Otherwise, the drum unit may deform. 4. When installing or replacing the cleaning blade, release the pressure several times manually, and then hold down the - Ricoh FW780 | Service Manual - Page 130

roller. 4. Be careful not to damage the hot roller thermistor and pressure roller thermistor when removing and reinstalling hot roller or the pressure roller. setting to the mode which is one step lower than the proper setting for the particular kind of paper. For example, if the proper setting is - Ricoh FW780 | Service Manual - Page 131

on the copy using a cotton cloth approximately 5 times. 6. Check whether the toner is peeled off on the areas that correspond with the scraped parts of the pressure roller. If white lines and/or bands appear, the pressure roller should be replaced with a new one. 7. Before turning the main switch - Ricoh FW780 | Service Manual - Page 132

- Ricoh FW780 | Service Manual - Page 133

REPLACEMENT AND ADJUSTMENT - Ricoh FW780 | Service Manual - Page 134

- Ricoh FW780 | Service Manual - Page 135

Lower Front, Right Lower Middle, and Right Lower Rear Covers 1. Open the paper path section. 2. Remove the right lower cover [E] (2 screws), right lower middle cover [F], and toner collection bottle [G]. 3. Remove the right lower rear cover [H] (1 screw). 1.3 REAR COVER REMOVAL 1.3.1 Rear Cover - Ricoh FW780 | Service Manual - Page 136

and right upper covers. 2. Remove the copy tray [A]. 3. Push the projections [B] into the holes [C] of the rear side of the original feed unit as shown and remove the operation panel [D] (2 connectors). 4. Open the original feed unit [E] and unhook the stoppers [F] at both ends. 5. Turn the original - Ricoh FW780 | Service Manual - Page 137

the exposure glass. 2. Remove the front original guide plate [D] (2 screws). NOTE: If the exposure lamp is too tight to be turned, remove one side of the exposure lamp socket (1 screw) and remove the exposure lamp. 3. Turn the exposure lamp [E] 1/4 of a turn and remove. NOTE: Make sure that the - Ricoh FW780 | Service Manual - Page 138

2.4 FIBER OPTICS ARRAY REMOVAL [C] [B] [D] [A] 1. Follow the steps from 1 to 3 of the exposure lamp removal. 2. Remove the original registration sensor bracket [A] (1 screw). 3. Lift up the fiber optics array [B] and remove it from the left side by sliding it out to the right side as shown. NOTE: - Ricoh FW780 | Service Manual - Page 139

2.5 LIGHT SENSOR REPLACEMENT [A] Rev. 5/95 1. Remove the exposure lamp. 2. Replace the light sensor [A] (1 screw, 1 connector). 3. Perform light sensor adjustment. See page 5-39 SM 5-5 A163 - Ricoh FW780 | Service Manual - Page 140

3. DEVELOPMENT 3.1 DEVELOPMENT UNIT REMOVAL [B] [A] [C] 1. Remove the left and right upper cover. 2. Open the paper path section and original feed unit. 3. Remove the toner supply cover [A]. 4. Remove the manual entrance feed cover [B] (2 pins). 5. Remove the paper feed driven unit [C] (2 screws and - Ricoh FW780 | Service Manual - Page 141

the 14p connector [C] and remove it out of the cutout [D]. 8. Remove the development unit [E]. CAUTION: Do not loosen the painted screws [F] which determine the development doctor blade height and do not push the doctor blade [G] too strongly, otherwise the doctor gap may change. SM 5-7 A163 - Ricoh FW780 | Service Manual - Page 142

Remove the toner supply unit casing [B] (2 pins) and development filter [C] and bracket [C] and clean them. 3. Stand up the development unit as shown (the drive section of the unit is the upper side). 4. Turn the paddle roller knob [D] clockwise. The developer will fall out onto the paper. 5. Repeat - Ricoh FW780 | Service Manual - Page 143

DENSITY SENSOR REPLACEMENT [C] [E] [D] [B] [A] 1. Remove the development unit. 2. Disconnect the harness connector [A] and take the harness from the 2 clamps [B]. 3. Remove the 2 screws [C] of the toner density sensor holder. 4. Pull out the harness from the toner density sensor side until the relay - Ricoh FW780 | Service Manual - Page 144

3.4 PTL REPLACEMENT [B] [A] 1. Remove the paper feed driven unit (follow the steps from 1 to 5 of the development unit removal). 2. Remove the PTL assembly [A] (4 screws, 3 connectors, and 4 clamps [B]). A163 5-10 SM - Ricoh FW780 | Service Manual - Page 145

DEVELOPMENT BIAS VOLTAGE ADJUSTMENT NOTE: This adjustment is required when the charge/bias/grid power pack is replaced. Preparation: 1. Turn off the main switch, and remove the rear cover mode and select No. --20. 2. Press the key to turn on the bias voltage. 3. Check the multimeter. If the - Ricoh FW780 | Service Manual - Page 146

± 10V 1. Access SP mode and select No. --21. 2. Press the key to turn on the bias voltage. 3. Check the multimeter. If the voltage is not that of the standard voltage, press the key and then change the voltage using and keys. 4. If the voltage is within the standard, press the key. A163 - Ricoh FW780 | Service Manual - Page 147

[B] and disconnect the harness connector [C]. 4. Remove the drum unit [D]. 5. Place the drum unit on the flat floor. NOTE: (1) When reinstalling the drum unit, hook the drum unit guides [E] on the pins [F] of the copier side plates. (2) Hold both ends of the drum unit to carry it. SM 5-13 A163 - Ricoh FW780 | Service Manual - Page 148

with the pick-off pawls when removing or reinstalling the drum. 4. Remove the drum [C] with the drum shaft. 5. Loosen the drum knob [D] by turning it counter clockwise as shown. 6. Remove the drum flange [E]. 7. Replace the drum with new one. NOTE: when reinstalling the gear [F], make sure that the - Ricoh FW780 | Service Manual - Page 149

may deform. 2. When installing or replacing the cleaning blade, release the pressure [E] several times manually, and then hold down the cleaning blade gently along its entire length to ensure that the cleaning blade contacts the drum. Even if the drum is installed already, this action [F] can be - Ricoh FW780 | Service Manual - Page 150

4.4 CHARGE CORONA UNIT REMOVAL [A] [A] [B] 1. Remove the drum unit. 2. Remove the ground springs [A]. 3. Remove the charge corona unit [B] (2 connectors). NOTE: When reinstalling the charge corona unit, make sure that the 2 connectors (C for the - Ricoh FW780 | Service Manual - Page 151

unit. 2. Remove the 4 grid wires [A] (4 springs). 3. Remove the endblock covers [B]. 4. Replace the corona wire [C] (1 spring). NOTE: (1) Make sure sand paper,... etc.) as this will damage the corona wire. (5) Do not use any solvent to clean the wire as this will cause uneven charge on the drum. (6) - Ricoh FW780 | Service Manual - Page 152

PAWL UNIT REMOVAL [A] [B] 1. Remove the drum unit and place it as shown. 2. Remove the pressure spring [A] and pick-off pawl unit [B] (2 screws and 1 connector). NOTE: When installing and/or removing the pick-off pawl unit, do not press too strongly. Otherwise, the drum unit may deform. A163 5-18 - Ricoh FW780 | Service Manual - Page 153

charge/bias/grid power pack is replaced. 1. Turn off the main switch and remove the rear cover. 2. Connect the ground terminal of the multimeter turn on the grid voltage. 7. Check the multimeter. If the voltage is not that of the standard voltage, press the key and then change the voltage using - Ricoh FW780 | Service Manual - Page 154

for a wide range of environments at the factory. b) Drum current adjustment is necessary whenever the power packs are replaced: adjustment may also be necessary to correct problems with paper separation, incomplete toner transfer, or image density. c) Make sure that the main switch is turned off - Ricoh FW780 | Service Manual - Page 155

4. Install the drum unit [B] on the machine. [B] CAUTION: Be careful not to turn on the main motor. If the main motor accidentally turns on, some parts around the drum may be damaged. SM 5-21 A163 - Ricoh FW780 | Service Manual - Page 156

. 1. Connect all the terminals of the current measurement drum to the machine ground. 2. Disconnect the charge corona terminal key to turn on the charge corona. 8. Check the multimeter. If the voltage is not that of the standard voltage, press the key and then change the voltage using and keys - Ricoh FW780 | Service Manual - Page 157

is within that of the standard voltage, press the key. 8. Select SP mode No. --13. 9. Press the key to turn on the transfer corona. 10. Check the multimeter. Press the voltage using and --150 ± 5 µA. key and then change the keys so that the transfer current is dc 11. If the voltage is - Ricoh FW780 | Service Manual - Page 158

that of the standard voltage, press the key. 8. Select SP mode No. --15 9. Press the key to turn on the separation corona. 10. Check the multimeter. Press the key and then change the current using and ± 10 µA. keys so that the ac separation current is ac 350 11. If the voltage is - Ricoh FW780 | Service Manual - Page 159

the standard voltage, press the key. 17. Select SP mode No. --17. 18. Press the key to turn on the separation corona. 19. Check the multimeter. Press the key and then change the current using and ± 2.5 µA. keys so that the dc separation current is dc --20 20. If the voltage is within - Ricoh FW780 | Service Manual - Page 160

1. Remove the copier rear cover. 2. Open the exit cover [A] and remove the shoulder screws [B] at both ends. 3. Disconnect the connector [C] and flex the hinge arms [D] of the exit cover slightly to the outside of the exit unit shafts and remove. 4. Turn the exit unit 1/4 of a turn to the front - Ricoh FW780 | Service Manual - Page 161

the safety switch bracket. 7. Remove the 2 screws [C]. 8. While pressing down the fusing pressure release bar [D], pull out the fusing unit. NOTE: While pressing down the fusing pressure release bar [D], set the fusing unit on the guides [E] and align the cuts [F] to the side plates [G] at both ends - Ricoh FW780 | Service Manual - Page 162

[G] [J] [K] [I] [G] [A] [H] [A] [J] [I] NOTE: Be careful not to damage the hot roller thermistor when removing and reinstalling the hot roller. 1. Remove the fusing unit. 2. Remove the pressure springs [A]. 3. Remove the fusing lamp brackets [B] and cushions [C] (1 screw each). 4. Remove the - Ricoh FW780 | Service Manual - Page 163

fusing entrance guide [D]. 3. Remove the pressure roller stripper unit [E] (4 screws). 4. Lift up the pressure roller (access the pressure roller from the cut [F] of the frame), slide out the pressure roller shaft [G] to the left, then remove the pressure roller [H]. 5. Replace the pressure roller - Ricoh FW780 | Service Manual - Page 164

of the fusing unit removal. 2. Remove the pressure roller thermistor [A] (1 screw). 5.5 PRESSURE ROLLER STRIPPER UNIT REPLACEMENT 1. Follow step 1 to 5 of the fusing unit removal. 2. Remove the pressure roller stripper unit [B] (4 screws). 5.6 HOT ROLLER STRIPPER UNIT REPLACEMENT 1. Follow step 1 to - Ricoh FW780 | Service Manual - Page 165

1. Remove the fusing unit. 2. Remove the 4 screws [A] of the fusing stay. 3. Disconnect the thermofuse connector [B] from the fusing lamp harness [C]. 4. Remove the hot roller thermistor [D] (1 screw and 1 spring, 7 clamps [E]). 5.8 FUSING THERMOFUSE REPLACEMENT 1. Follow step 1 to 3 of the hot - Ricoh FW780 | Service Manual - Page 166

switch. 2. Remove the copier rear cover. 3. Remove the pressure roller thermistor screw and hang the thermistor by the harness. 4. Actuate the fusing exit safety switch [A]. 5. Turn on the main switch, select the normal fusing temperature mode, and wait for longer than 10 minutes. 6. Using a digital - Ricoh FW780 | Service Manual - Page 167

S CORONA UNIT REMOVAL [A] [B] [C] [C] [D] 1. Open the paper path section [A] and take out the T & S corona unit [B] (2 connectors [C]). NOTE: 1) Make sure that the T & S corona unit is set correctly by pressing it down when reinstalling. 2) Remove the connector cover [D] (1screw) for connecting the - Ricoh FW780 | Service Manual - Page 168

wires with rough material (sand paper, etc.) as this will damage the corona wire. (4) Do not use any solvent to clean the wire as this will cause uneven charging of the drum. 6.2.1 Preparation 1. Remove the T & S corona unit. 2. Remove the paper guides [A] and endblock covers [B]. A163 5-34 SM - Ricoh FW780 | Service Manual - Page 169

6.2.2 Separation Corona Wire Replacement 1. Remove the separation corona wire [C]. 2. Hook the new separation corona wire on the terminal [D] of the right endblock. NOTE: Make sure that the wire junction [E] is positioned inside the right endblock. 3. Hook the other side of the separation corona - Ricoh FW780 | Service Manual - Page 170

mylars [A] on the rear feed table. 1. Open the fusing exit cover [B] and exit unit [C]. 2. Remove the copy tray [D]. 3. Remove the rear feed table assembly [E] (2 screws and 1 connector). 4. Unhook the blower duct [F] and remove. 5. Unhook the fan support - Ricoh FW780 | Service Manual - Page 171

7.2 ANTICONDENSATION HEATER INSTALLATION [C] [A] [B] [C] 1. Remove the rear cover of the machine (2 screws). 2. Remove the T&S corona unit. 3. Install the anticondensation heater [A] (3 screws). 4. Put the harness of the heater into the cutout [B] of the frame. 5. - Ricoh FW780 | Service Manual - Page 172

Grid power pack, or to correct certain problems with image density after checking all other possible causes. NOTE: Adjusting grid voltage will not affect toner supply amount, but will affect the amount of charge reaching the drum. Exposing the the drum to light will not disipate all residual voltage - Ricoh FW780 | Service Manual - Page 173

How: 1. Every Call 2. When replacing the following part • Exposure lamp • Light sensor • Drum • RAM on the main board To maintain the manual image density level is selected. Change SP #-6 setting. Change the light sensor voltage. 1. Turn off the main switch. 2. Clean the following parts - Ricoh FW780 | Service Manual - Page 174

the image density in black solid areas is acceptable. 2. Dirty background, where the problem is not caused by excess toner and cannot be solved by adjusting the light sensor voltage. To improve the copy image. SP #-20 Change the development bias voltage for image density control by SP #-20. SP #-20 - Ricoh FW780 | Service Manual - Page 175

wants to change the overall image density of the copies. To change toner concentration inside development unit. SP #-22 Change the toner density setting by SP #-22 NOTE: The toner density can also be adjusted using SP #-30 (toner density sensor voltage setting). To return SP #-30 to the initial - Ricoh FW780 | Service Manual - Page 176

- Ricoh FW780 | Service Manual - Page 177

TROUBLESHOOTING - Ricoh FW780 | Service Manual - Page 178

- Ricoh FW780 | Service Manual - Page 179

TROUBLESHOOTING 1.1 LOW IMAGE DENSITY Is the used paper moist or extremely dry? No Yes Replace the paper. Is the toner sensor voltage within the no toner supply level (level 0) ? (Refer to Page 2-16.) Yes No Is there sufficient toner in the cartridge? Yes No Replace the toner cartridge - Ricoh FW780 | Service Manual - Page 180

even? Yes No Is the developer level in the development unit? Yes No Check and correct the machine level. Clean the charge corona wire, grid wire, and transfer corona wire. Check if they are correctlsyet on the slots of the end blocks. Clean the optics. If the problem is not fixed, replace the - Ricoh FW780 | Service Manual - Page 181

level 0 and 1? (Check using SP#--32 referring to Page 2-16.) No Yes Check the main board and toner supply clutch. Is the image density of solid areas high? No Yes Check the toner sensor. Make several blank copies. Is the background still dirty? Yes No Check the cleaning blade. Are the grid voltage - Ricoh FW780 | Service Manual - Page 182

Cleaning blade • Development unit • Drum NOTE: If the separation corona leakage is detected, the separation corona will be turned off. This condition will not be reset until the main switch is turned off and on. If the separation corona does not turn on, a black band appears 250 mm from the paper - Ricoh FW780 | Service Manual - Page 183

BLANK COPY Is the used paper moist? No Yes Replace the paper. Are the terminals of the charge corona unit and the T& S corona unit connected properly? Yes No Set the terminals properly. Is the charge corona wire or the T & S corona wire broken? No Yes Replace the broken part. Are the charge - Ricoh FW780 | Service Manual - Page 184

CREASING Is the used paper moist? No Yes Change the paper. Is the paper feed direction the same as the paper fiber direction? No Yes Change the paper transport direction, if possible.(NOTE 1.) Decrease the fusing temperature using SP mode #1 to #3.(NOTE 2.) NOTE: 1. If there is rib shape creasing - Ricoh FW780 | Service Manual - Page 185

B1, -B2, -A29 -A30) 2.2 SC Code E-2: Fusing Thermofuse Open -DefinitionThe temperature detected by the hot roller thermistor does not reach 100 C within 4 minutes and 30 seconds after the main switch is turned on. Fusing thermofuse Hot roller thermistor AC drive board (T202-2, RA201 - Ricoh FW780 | Service Manual - Page 186

than 0.11 KΩ. Hot roller thermistor Main board (CN106-A2, -A5, -B11, -B14, -B15) 2.5 SC Code E-5: Pressure Roller Thermistor Open -DefinitionThe resistance of the pressure roller thermistor is more than 0.53 MΩ. Pressure roller thermistor Main board (CN106-A2, -A4 - Ricoh FW780 | Service Manual - Page 187

Code E-6: Pressure Roller Thermistor Short -DefinitionThe resistance of the pressure roller thermistor is less than 0.55 KΩ. Pressure roller thermistor Main board (CN106-A2, -A5, -B11, -B14, -B15) 2.7 SC Code E-7: Fusing Overheat -DefinitionThe temperature detected by the hot roller - Ricoh FW780 | Service Manual - Page 188

12 minutes after main switch is turned on. Hot roller thermistor Fusing lamp Fusing thermofuse AC drive board (T202-2, RA201-T4) Main board (CN106-A2, -A5, -B11, -B14, -B15) AC harness 2.9 SC Code E-9: Toner Density Sensor Abnormal -DefinitionThe toner density sensor voltage is less - Ricoh FW780 | Service Manual - Page 189

main motor drive Main board (CN106-A12, -A13) 2.11 SC Code E-11: Toner Density Sensor adjustment Error -DefinitionThe toner density sensor voltage cannot be adjusted to its standard value (4.1 ±0.1 volts) during the new developer initialization. NOTE: If clearing the SC condition, the previous data - Ricoh FW780 | Service Manual - Page 190

3.1 POWER SUPPLY UNIT Europe version Fuse No. FU1 FU2 FU3 FU4 Specification 250V 4A 250V 6.3A 250V 6.3A 250V 6.3A Symptom No power. No indication. Beeper sounds. E=10 is indicated. Not used. USA version Fuse No. Specification Symptom FU1 125V 8A No power. FU2 250V 5A No indication - Ricoh FW780 | Service Manual - Page 191

ROLL FEEDER - Ricoh FW780 | Service Manual - Page 192

- Ricoh FW780 | Service Manual - Page 193

1. SPECIFICATIONS Roll Paper Size: Cut Size: Cutting Time: Paper Transport Velocity: Repeat Quantity: Control: Power Source: Power Consumption: second 50 mm/s 1 to 99 Microprocessor +24 volts and +5 volts from the copier Maximum 110 W 1,080 mm x 475 mm x 295 mm 42.71" x 18.70" x 11.61" 29 - Ricoh FW780 | Service Manual - Page 194

2. MECHANICAL COMPONENT AND DRIVE LAYOUT 4 5 3 2 1 7 6 8 6 5 7 1. Paper Feed Motor 2. Idle Pulley 3. Timing Belt 4. Cutter Motor 5. Paper Feed Rollers 6. Paper Roll Spool 7. Paper Roll 8. Cutter Unit A163 7-2 SM - Ricoh FW780 | Service Manual - Page 195

Also detects the leading edge of the 42 paper to start the paper length pulse count. Detects humidity and turns on the RF antihumidity heaters 34 while copier CPU. Others Upper RF Removes humidity from the roll paper 41 Antihumidity Heater Lower RF Removes humidity from the roll paper - Ricoh FW780 | Service Manual - Page 196

A163 7-4 SM - Ricoh FW780 | Service Manual - Page 197

The paper feed rollers [A], which are turned by the paper feed motor, feed paper from the paper roll [B] through the cutter unit [C] to the paper leading edge sensor [D] according to the signal from the copier. When the paper feed motor starts, the copier CPU starts measuring the length of the paper - Ricoh FW780 | Service Manual - Page 198

leading edge of the paper reaches the exit rollers [A], the paper is directed to the copier registration roller [B]. The registration roller stops rotating after the registration sensor [C] detects the leading edge of the copy paper. The copy paper is fed to the registration roller and stops to wait - Ricoh FW780 | Service Manual - Page 199

gears [B] when the roll cutter unit is unlocked from the lower position and lifted up. At this time, the cutter unit is locked at the upper position by the lock lever [C], and the wheel [D] on the right side can be rotated manually to position the leading edge of the roll paper. SM 7-7 A163 - Ricoh FW780 | Service Manual - Page 200

The cutter unit uses a sliding rotary cutting blade [A] which is pulled past a fixed blade by a drive wire. The rotary cutting blade allows the cutter unit to cut paper in both directions. There are home position switches [B] at both ends of the cutter unit. The cutter motor turns off, stopping the - Ricoh FW780 | Service Manual - Page 201

5. SERVICE TABLES 5.1 TEST POINTS Function GND VA (24 V) VC (5 V) TP No. TP903 TP901 TP902 5.2 BLOWN FUSE CONDITION Component F901 (250V/1.0A) Unit RF Main board Symptom The AC line for the R/F antihumidity heaters is cut. The heaters are not turned on. SM 7-9 A163 - Ricoh FW780 | Service Manual - Page 202

6. INSTALLATION PROCEDURE Roll Feeder (A571) CAUTION: Unplug the copier power cord before starting the following procedure. Check the accessories and their quantities according to the following list: Harness Cover 2 pcs Angle Bracket 1 pc Spacer 1 pc Small Cap 1 pc Screws - M4x8 8 pcs Screws - Ricoh FW780 | Service Manual - Page 203

[B] [C] [C] [G] [H] [F] 1. Lower the feet [A] so that the table does not move while the roll feeder is being installed on the table and the copier. NOTE: Do not place the roll feeder unit [B] onto the floor roughly, to prevent the left and right covers from being damaged. 2. Remove the shipping - Ricoh FW780 | Service Manual - Page 204

[G] 5. Open the copier paper path section and remove the copier left lower cover [A] (2 screws), lower right front cover [B] (2 screws), lower right middle cover [C], toner collection bottle [D], and rear cover [E] (2 screws). 6. Remove the small caps [F] from the copier rear cover using cutting - Ricoh FW780 | Service Manual - Page 205

[A] [D] [B] [C] NOTE: Take care not to drop the manual feed table when removing the bracket [A]. 8. Remove the lower front cover [B] (2 screws), reinforcement plate [C] (1 screw), bracket [A] (4 screws) (which is changed by the harness), and the manual feed table [D]. [C] SM 7-13 A163 - Ricoh FW780 | Service Manual - Page 206

[A] [B] [D] [E] [F] 9. Mount the roll feeder unit on the copier (hook the mounting arms [A] on both sides into the mounting rail [B]). NOTE: Lift the unit by holding the plate [C] just under the size marks. 10. - Ricoh FW780 | Service Manual - Page 207

[H] (1 screw with spring washer)}. 15. Connect the roll feeder heater harness connector [I] to the copier ac drive board connector. 16. Install the harness covers [J] (1 screw each). 17. Reinstall Manual Feed Table 18. Reattach all the covers and manual feed table excluding the roll feeder right - Ricoh FW780 | Service Manual - Page 208

. 45 46 47 18. Plug in the power supply cord and turn on the main switch. 19. Press the following keys on the than 3 seconds. The roll paper end and call service indicators will blink (SP mode). 21. Select 40 using the + and - keys. cover. 25. Check the roll feeder operation. A163 7-16 SM - Ricoh FW780 | Service Manual - Page 209

next to the original screw holes. 7.1.2 Left and Right Cover NOTE: Be careful not to drop and damage the lower front cover [B]. 1. Remove the left and right covers [C and D] (3 screws each). NOTE: When reattaching the left and/or right covers, unlock and lift the cutter unit for easier assembly. SM - Ricoh FW780 | Service Manual - Page 210

UNIT REMOVAL [C] [D] [A] [B] [A] 1. Remove the roll feeder left and right covers. 2. Remove the 4 screws [A] of the cutter unit. 3. Take out the cutter unit [B] (1 connector [C]). NOTE: When reinstalling the cutter unit, attach the cutter unit cover [D] with the cutter unit. A163 7-18 SM - Ricoh FW780 | Service Manual - Page 211

the cutter unit. 2. Unlock and lift the paper feed roller unit [A] using the release lever [B]. 3. Remove the release lock lever [B] (2 screws). 4. Remove the feed roller guide plate [C] (6 screws). 5. Replace the paper feed roller [D] (2 allen screws [E], 1 gear [F], 1 snap ring [G], 2 bushings - Ricoh FW780 | Service Manual - Page 212

MOTOR TIMING BELT TENSION ADJUSTMENT [A] [B] If the timing belt tension for the paper feed motor is not correct, the paper cut length varies for each copy paper. Readjust the timing belt tension for the paper feed if this occurs. 1. Remove the small cap [A] (2 screws). 2. Loosen the screw [B] and - Ricoh FW780 | Service Manual - Page 213

when the roll feeder is installed to correct cutting errors. The cut error correction data is determined in the factory without the copier installed. The cut length varies depending on the copier on which it is installed and/or paper type used. If required, adjust the cut length as follows: NOTE - Ricoh FW780 | Service Manual - Page 214

from the roll feeder unit. NOTE: 594 mm wide paper is easier to adjust than 841 mm wide paper. 3. Measure the lengths [C] and [D]. 4. Loosen the 2 screws [E] which determine the paper spool height. 5. If C > D, lower the right side of the paper spool. If C < D, do the opposite. 6. Make another copy - Ricoh FW780 | Service Manual - Page 215

A251/A252 Service Manual The A251/A252 machines are based on the A163 copier. Only the differences from the base copier are described in the following pages. Therefore, this documentation should be treated as an insert version of the base copier's service manual. It should always be utilized - Ricoh FW780 | Service Manual - Page 216

- Ricoh FW780 | Service Manual - Page 217

1-7 2. DETAILED SECTION DESCRIPTIONS 2-1 2.1 DRUM ...2-1 2.1.2 DRUM DRIVE...2-1 2.3 EXPOSURE 2-2 2.3.2 PAPER AND ORIGINAL FEED (A252 ONLY 2-2 2.4 DEVELOPMENT 2-4 2.4.2 TONER DENSITY CONTROL 2-4 2.8 FUSING AND PAPER EXIT 2-5 2.8.1 OVERVIEW (A252 COPIER 2-5 3. INSTALLATION 3-1 3.1 INSTALLATION - Ricoh FW780 | Service Manual - Page 218

WIRE REPLACEMENT 5-9 5.8 COPY QUALITY ADJUSTMENT 5-11 5.8.4 REGISTRATION ADJUSTMENT 5-11 6. TROUBLESHOOTING 6-1 6.2 SERVICE CALL CONDITIION 6-1 6.2.12 SC CODE E-14: ZERO CROSS SIGNAL DETECTION ABNORMAL 6-1 6.2.13 SC CODE E-15: MAIN SWITCH ABNORMAL (U.S.A. VERSION ONLY 6-1 6.3 BLOWN FUSE TABLE - Ricoh FW780 | Service Manual - Page 219

check has to be made with exterior covers off or open while the main switch is turned on, keep hands away from electrified or mechanically driven components. 5. The inside and the metal parts of the fusing unit become extremely hot while the copier is operating. Be careful to avoid touching - Ricoh FW780 | Service Manual - Page 220

Do not incinerate the toner cartridge or the used toner. Toner dust may ignite suddenly when exposed to open flame. 2. Dispose of used toner, developer, and organic photoconductors according to local regulations. (These are non-toxic supplies.) 3. Dispose of replaced parts in accordance with local - Ricoh FW780 | Service Manual - Page 221

POSITION 2 TAB POSITION 3 A251/A252 OVERALL MACHINE INFORMATION A251/A252 DETAILED SECTION DESCRIPTIONS A251/A252 INSTALLATION A251/A252 SERVICE TABLES A251/A252 REPLACEMENTS AND ADJUSTMENT A251/A252 TROUBLESHOOTING TAB POSITION 4 TAB POSITION 5 TAB POSITION 6 TAB POSITION 7 TAB POSITION 8 - Ricoh FW780 | Service Manual - Page 222

- Ricoh FW780 | Service Manual - Page 223

A252 and A174 WIDE FORMAT COPIERS. Configuration Copy Speed First Copy Warm-up Time Multiple Copy Paper Feed Syncronized Cut Mode Fusing Lamp Self Diagnostic Codes Mechanical Component Layout Drive Layout Drum Area Drum Drive Charge Charge Corona Circuit Auto. Charge Wire Cleaning Exposure Exposure - Ricoh FW780 | Service Manual - Page 224

- Ricoh FW780 | Service Manual - Page 225

OVERALL INFORMATION - Ricoh FW780 | Service Manual - Page 226

- Ricoh FW780 | Service Manual - Page 227

induction sensor Development bias control + exposure control Dual wire ac corona and pick-off pawls Cleaning blade Manual feed (roll feeder optional) Heat and pressure type, teflon (upper) and silicone rubber (lower) rollers Nichrome wire lamp (115 V: 1,100 W, 230 V: 1,100 W) 13 codes, displayed in - Ricoh FW780 | Service Manual - Page 228

guide (A569-06) Additional equipment Table (A714-05) - - Table (A836-00) Table (A836-00) - NOTE: 1) Roll cutting rail cannot be installed on the A252 copier. 2) Key counter cannot be installed on these copiers. Other Optional Equipment • Paper Spool • Drum anti-condensation heater Specifications - Ricoh FW780 | Service Manual - Page 229

Overall Information 1.2 PAPER PATH - A251 copier - A A B D E C PAPER PATH - A252 copier E F D B C A252V500.PCX A: Original Path (A251 copier) B: Paper from the manual feed C: Paper from the roller feed D: Paper exit E: Original Path from Rear Feeder F: Original Path (A252 copier): Switching - Ricoh FW780 | Service Manual - Page 230

4. Exit Rollers 5. Fusing Exit Rollers 6. Hot Roller 7. Pressure Roller 8. Gas Spring 9. OPC Drum 10. T/S Corona Unit 11. Main Drive Unit 12. Table 13. Paper Spool A251/A252 A252V502.PCX 14. Roll Feeder 15. Paper Registration Rollers 16. Development Unit 17. Toner Cartridge 18. Manual Feed Table - Ricoh FW780 | Service Manual - Page 231

Information 28 31 29 MECHANICAL COMPONENT 32 26 30 27 A252V505.WMF 26. Original Guide 27. Rear Copy Tray (Option Copy Tray) 28. Original Feed Motor 29. Original Entrance Roller 30. Original Rear Roller 31. Original Entrance Press Roller 32. Original Rear Press Roller SM 1-5 A251/A252 - Ricoh FW780 | Service Manual - Page 232

10 4 5 6 A252V503.WMF 9 8 7 17 - A252 copier only 19 18 A252V501.WMF 1. Original Feed Roller Pulley 2. Original Feed Roller One Way Pulley 3. Development Unit 4. Development Unit Relay Gear 5. Development Drive Chain 6. Paper Registration Roller Clutch 7. Drum Drive Relay Gear 8. Main Motor - Ricoh FW780 | Service Manual - Page 233

rollers. 30 Toner Supply Turns on to supply toner to the development unit. 31 Solenoids Pick-off Pawl Moves the pick-off pawls against the drum. 6 Switches Main Supplies power to the copier. 17 Original & Paper Feed Safety Cuts AC power when the original or paper feed unit is opened - Ricoh FW780 | Service Manual - Page 234

, charge grid, and development bias. 19 Transfer/Separation Provides high voltage power for the transfer corona and separation. 16 Thermistors Hot Roller Monitors the hot roller's surface temperature. 8 Pressure Roller Monitors the pressure roller's surface temperature. 11 Thermofuses - Ricoh FW780 | Service Manual - Page 235

DETAILED DESCRIPTIONS - Ricoh FW780 | Service Manual - Page 236

- Ricoh FW780 | Service Manual - Page 237

The drum and flanges turn together when the main motor is on. At this time, the drive is also transmitted to the original feed rollers [G] through the original feed drive pulley [H] and belt [I] (A251 copier). The original feed rollers [J] (original entrance and rear rollers) for the A252 copier are - Ricoh FW780 | Service Manual - Page 238

PAPER AND ORIGINAL FEED (A252 ONLY) [D] [B] [C] [G] [H] 26 mm [F] [I] [J] [K] 15 mm J: Original Rear Roller K: Original Rear Sensor [A] [E] A252D500.WMF A252D501.WMF In this machine (A252 copier quenching lamp, development bias, and PTL begin. Then, the exposure lamp turns on. To - Ricoh FW780 | Service Manual - Page 239

paper feed motor turn on again after the trailing edge of the original passes the original entrance sensor. The paper feed resumes and the copy paper is transported to the drum [I]. To measure the original length for synchro-cutting, the copier in the original entrance roller. During this procedure - Ricoh FW780 | Service Manual - Page 240

DEVELOPMENT 2.4 DEVELOPMENT 2.4.2 TONER DENSITY CONTROL Recovery from Toner End Condition After replacing the toner cartridge (opening and closing the original feed unit), the main motor rotates the development unit for 60 seconds. During this period, toner is supplied at 100% of the supply amount - Ricoh FW780 | Service Manual - Page 241

(A252 COPIER) The copy paper is delivered to the lower paper exit. The location of the fusing exit sensor is different from the A163 and A251 copier. Except for this difference, the A252 copier is identical to the with A251 and A163 copiers. Please refer to A163 copier service manual for details - Ricoh FW780 | Service Manual - Page 242

- Ricoh FW780 | Service Manual - Page 243

INSTALLATION - Ricoh FW780 | Service Manual - Page 244

- Ricoh FW780 | Service Manual - Page 245

80% RH 3. Ambient Illumination: 4. Ventilation: 5. Ambient Dust: Less than 1,500 lux (do not expose to direct sunlight). Minimum space 20 m3 Room air should turn over at least 30 m3/hr/person. Less than 0.15 mg/m3 (4 x 10-3 oz/yd3) 6. If the installation place is air-conditioned or heated, place - Ricoh FW780 | Service Manual - Page 246

) A252I505.WMF 3.1.3 MACHINE LEVEL 1. Front to back: Within 5 mm (0.2") of level 2. Right to left: Within 5 mm (0.2") of level Make sure that the machine is level using a carpenter's level. A251/A252 3-2 SM - Ricoh FW780 | Service Manual - Page 247

INSTALLATION REQUIREMENTS 3.1.4 POWER SOURCE 1. Input Voltage Level: 120 V, 60 Hz More than 15 A (for U.S.A. version) 220 ~ 240 V, 50/60 Hz More than 7 A (for European version) 2. Permissible Voltage Fluctuation: ±10% 3. Do not set anything on the power cord. NOTE: 1) Make sure the plug is - Ricoh FW780 | Service Manual - Page 248

INSTALLATION PROCEDURE 3.2.1 COPIER Accessory Check Check the accessories and their quantities according to the following list: - A252 copier - Original Guide 6 pcs Operating Instruction Holder 1 pc - A251 copier Guide Wire 2 pcs Copy Tray 1 pc Copy Guide 1 pc Operating Instruction Holder 1 pc - Ricoh FW780 | Service Manual - Page 249

[A] A252I500.WMF 1. Lower the feet [A] so that the table does not move while the copier is being installed on the table. 2. Place the copier [B] on the table [C] (Place the copier feet [D] into the table holes [E]). WARNING The copier is not attached to the table. Pushing the copier too hard may - Ricoh FW780 | Service Manual - Page 250

.WMF [C] [E] A252I510.WMF [D] [F] [E] A252I502.WMF 3. Open the paper path section [A]. 4. Remove the right upper cover [B] (2 screws). 5. Remove the drum protection sheet [C] and remove the screw [D] to apply cleaning blade pressure to the drum. 6. Open the fusing exit section. Remove the two - Ricoh FW780 | Service Manual - Page 251

manual feed table [C], and toner supply cover [D]. Remove a sheet [E] covering the developer entrance. Pour 1 kg of the developer [F] into the development unit evenly across its width as shown. NOTE: Close the paper path section while opening the toner supply cover. Otherwise, the toner supply cover - Ricoh FW780 | Service Manual - Page 252

.WMF NOTE: If the fusing temperature is lower than 60°C when the main switch is turned on, the main motor will rotate. In this case, it is not necessary to access the SP mode to load the total 2kg of developer (Steps 11 to 14). Turn off the main switch to stop the main - Ricoh FW780 | Service Manual - Page 253

. The roll paper end and call service indicators will blink (SP mode). 17. Select 36 using the + and - keys. Enter "1" by pressing the following keys. Function Select key [E] + key RF Select key [F] Five minutes later, the copier - Ricoh FW780 | Service Manual - Page 254

INSTALLATION PROCEDURE [A] [B] [C] A252I507.WMF 18. Install the toner cartridge [A] as shown. 19. Remove the sealing tape [B] from the cartridge and turn the knob [C] until it stops. A251/A252 3-10 SM - Ricoh FW780 | Service Manual - Page 255

A252I506.WMF Installation A252I509.WMF A252 copier only (step 20) 20. Install the original guides [A]. A251 copier only (step 21 and 22) 21. Attach the guide wires [B] to the copy tray [C]. 22. Install the copy tray [C] and copy guide [D]. 23. Reinstall all the covers. 24. Check the copy quality - Ricoh FW780 | Service Manual - Page 256

INSTALLATION PROCEDURE 3.2.2 TABLE (A836) Accessory Check Check the accessories and their quantities according to the following list: Top Plate 1 Left Side Plate 1 Right Side Plate 1 Middle Plate 1 Rear Cover 1 Screws with Spring Washer - M4 x 8 14 A251/A252 3-12 SM - Ricoh FW780 | Service Manual - Page 257

the top plate [C], left [D], and right side plate [E] (6 screws). 2. Turn the table up-side down in the direction of A. 3. Install the middle plate [F] and rear cover [G] (4 screws each). NOTE: If the optional copy tray is installed after copier installation, install the front copy tray stay [I] and - Ricoh FW780 | Service Manual - Page 258

Copy Tray Support 1 Copy Tray Guide 2 Copy Tray Sheet 3 Nylon Clamp 1 Rear Copy Tray 3 Copy Tray Stopper 2 Screw 13 Rear Copy Tray Sheet - Short 2 Rear Copy Tray Sheet - Center 1 NOTE: The copy tray is an option for the A252 copier. When the copy tray is installed on the copier - Ricoh FW780 | Service Manual - Page 259

. If the copy tray is installed after the copier installation, remove the roll feeder and copier from the table, then loosen the screws of the table, then do step 1. 2. Install the copy tray guides [C] (1screw each). 3. Install the copy tray support [D] (2 truss screws). SM 3-15 A251/A252 - Ricoh FW780 | Service Manual - Page 260

holes [C] on the rear copy tray stay [D] as shown in the illustration. 5. Hook the rear copy trays [E] onto the rear copy tray stay [D]. 6. Secure the copier power supply cord [F] to prevent the cord from interfering with the paper path (1 nylon clamp [G] and 1 screw). A251/A252 3-16 SM - Ricoh FW780 | Service Manual - Page 261

[C] A836I506.WMF [A] [B] [A] [B] A836I508.WMF 7. Adhere the rear copy tray sheet - center (long) [A] and the two rear copy tray sheets - short [B] onto the exit cover as shown. 8. Adhere the copy tray stoppers [C] to the front side of the table middle plate [D]. SM 3-17 A251/A252 - Ricoh FW780 | Service Manual - Page 262

INSTALLATION PROCEDURE 3.2.4 ROLL FEEDER (A571) CAUTION Unplug the copier power cord before starting the following procedure. Accessory Check Check the accessories and their quantities according to the following list: Harness Cover 2 pcs Angle Bracket 1 pc Spacer 1 pc Small Cap 1 pc Screws - M4 - Ricoh FW780 | Service Manual - Page 263

A571I501.WMF [H] [B] [F] A571I502.WMF 1. Lower the feet [A] so that the table does not move while the roll feeder is being installed on the table and the copier. NOTE: Do not place the roll feeder unit [B] onto the floor roughly, to prevent the left and right covers from being damaged. 2. Remove - Ricoh FW780 | Service Manual - Page 264

.WMF 5. Open the copier paper path section and remove the copier left lower cover [A] (2 screws), lower right front cover [B] (2 screws), lower right middle cover [C], toner collection bottle [D], and rear cover [E] (2 screws). 6. Remove the small caps [F] from the copier rear cover using cutting - Ricoh FW780 | Service Manual - Page 265

.WMF NOTE: Take care not to drop the manual feed table when removing the bracket [A]. 8. Remove the lower front cover [B] (2 screws), reinforcement plate [C] (1 screw), bracket [A] (4 screws) (which is changed by the harness), and the manual feed table [D]. Installation SM 3-21 A251/A252 - Ricoh FW780 | Service Manual - Page 266

INSTALLATION PROCEDURE [A] [B] [D] [E] [F] A571I507.WMF [C] A571I508.WMF 9. Mount the roll feeder unit on the copier (hook the mounting arms [A] on both sides into the mounting rail [B]). NOTE: Lift the unit by holding the plate [C] just under the size marks. 10. - Ricoh FW780 | Service Manual - Page 267

heater harness connector [I] to the copier ac drive board connector. 16. 220 ~ 240 V versions only Install the ground plates [L, M] (1 screw with spring washer and 1 washer each). 17. Install the harness covers [J] (1 screw each). 18. Reattach all the covers and manual feed table excluding the roll - Ricoh FW780 | Service Manual - Page 268

. 45 46 47 19. Plug in the power supply cord and turn on the main switch. 20. Press the following keys on the than 3 seconds. The roll paper end and call service indicators will blink (SP mode). 22. Select 40 using the + and - keys. cover. 26. Check the roll feeder operation. A251/A252 3-24 SM - Ricoh FW780 | Service Manual - Page 269

SERVICE TABLES - Ricoh FW780 | Service Manual - Page 270

- Ricoh FW780 | Service Manual - Page 271

except for the following are common with the A163 copier. Please refer to the A163 copier service manual. Service Program Mode Table Mode No. Function Data Paper Feed Out Refer to the A163 service manual for details. 0: 2 minutes Waiting Time The paper from the roll feeder is fed out only - Ricoh FW780 | Service Manual - Page 272

page 4-13 of this manual for details. 0, 1, 2, 3, 4, 7, 8, 9, 11, 12, 13, and 18 *33 Not Used Semi-synchro-cut Adjusts the cut length in the semi-synchro 48 Length Adjustment cut mode (A251 copier only). -10 (Shorter) ← 0 → 10 (Longer) 0.1 %/step Main Motor Speed (Jam code numbers have been - Ricoh FW780 | Service Manual - Page 273