HP Scitex FB10000 Site Preparation Guide Rev. 2 - Page 18

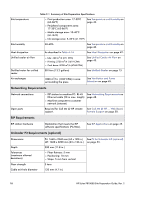

Networking Requirements, RIP Requirements, Unloader Pit Requirements optional

|

View all HP Scitex FB10000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

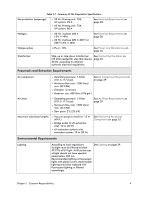

Table 2-1 Summary of Site Preparation Specifications Site temperature • Print production area: 17-30°C (63-86°F) • Peripheral components area: 17-30°C (63-86°F) • Media storage area: 10-40°C (50-104°F) • Ink storage area: 5-35°C (41-95°F) See Temperature and Humidity on page 40. Site humidity 50-60% See Temperature and Humidity on page 40. Heat dissipation As described in Table 4-14. See Heat Dissipation on page 42. Unified cooler air flow • Idle: 460 m3/h (271 CFM) • Printing: 2750 m3/h (1619 CFM) • Cool down: 8100 m3/h (4768 CFM) See Unified Cooler Air Flow on page 43. Distilled water for unified cooler 50 liters (13.2 gallons) See Unified Cooler on page 13. Air exchanges 1800 m3/hr. (1059 CFM) in area surrounding the press See Ventilation and Fume Extraction on page 45. Networking Requirements Network connections Open ports • RIP station to machine PC: RJ-45 Ethernet cable (20 m max. length) • Machine computer to customer network (internet) See Networking Requirements on page 48. Required for Call Me @ HP remote See Call Me @ HP - Web Based support. Remote Support on page 50. RIP Requirements RIP station hardware Workstation that meets the RIP software specifications (PC/Mac). See RIP Applications on page 49. Unloader Pit Requirements (optional) Dimensions Depth Tolerances (maximum allowed deviations) Floor strength Cable exit hole diameter Pit: 1640 x 3240 mm (65 x 128 in.) See Pit for Unloader Lift (optional) Lift: 1600 x 3200 mm (63 x 126 in.) on page 53. 300 mm (11.8 in.) • Floor flatness: 5 mm • Positioning: 10 mm • Slope: 5 mm from vertical 3 tons 120 mm (4.7 in.) 10 HP Scitex FB10000 Site Preparation Guide, Rev. 2