HP Scitex FB10000 Site Preparation Guide Rev. 2 - Page 45

Surge Protection, Grounding, Additional Information

|

View all HP Scitex FB10000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 45 highlights

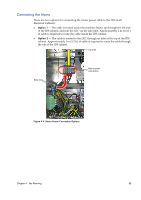

Surge Protection • The end-user facility should provide the proper surge protection, which will be suitable for their specific installation. • In order to ensure optimum performance and reliability, the FB10000 should be protected from variations in line voltage, which are common to production printing environments. Power lines should be regulated accordingly, using a dedicated power conditioning unit, unless the lines are centrally regulated. The air-conditioning unit should include a surge protector in order to avoid lightning damages. Grounding The FB10000 press must be connected to a special ground line in order to protect the operator and the printer and minimize electrostatic affects. Grounding equipment for the FB10000 press and all connecting equipment must be installed to ensure smooth and trouble-free operation. The following grounding requirements must be fulfilled: • Grounding wires should be insulated and at least equal in size to the phase conductors. • Ground impedance must be less than 0.1 ohms. • The installation of a single point and dedicated ground. • Power stabilizer equipment that is supplied by three uninterrupted phase wires and one uninterrupted copper ground wire from the main building service panel. These should run in the same conduit and should be at least equal in size to the phase wires. Additional Information • As a safety precaution, the FB10000 should be hardwired to a wall-mounted circuit breaker. This outlet should be suitably rated to meet the power requirements of the FB10000, and should be in accordance with the wiring standards of the country of installation. • All electrical cables that are stretched between the FB10000 and the machine components should be protected against mechanical hazard using suitable protection (see Figure 4-2 on page 26). Chapter 4 - Site Planning 37