HP Scitex FB10000 Site Preparation Guide Rev. 2 - Page 50

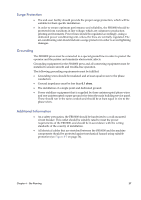

Heat Dissipation, Temperature and Humidity, Table 4-14

|

View all HP Scitex FB10000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 50 highlights

For example, if the substrates were shipped in 5°C conditions and the site is 25°C, allow 48 hours for the substrates to acclimatize to the site. The pallet should be unwrapped for printing only after the substrates have acclimatized. Substrates on the pallet that are not used for printing should be rewrapped immediately after the job is completed. Rewrapping the substrates helps preserve them in good condition for future jobs. Printed substrates should be kept under the same conditions defined for the print production area (see Temperature and Humidity on page 40) until the substrates are packaged for shipping. Caution Exposure to extreme heat or strong sunlight may result in permanent media damage. Heat Dissipation Sufficient air-conditioning is required to provide heat dissipation for the FB10000 system. Table 4-14 lists the sources of heat that should be considered when planning the climate control system. Table 4-14 Heat Dissipation of Various Components Component BTUs FB10000 press (including LEC, REC, BSU, and bridge) 10,000 BTUs UV cabinet 6,800 BTUs Unified cooler 87,350 BTUs Vacuum unit 20,000 BTUs UV extraction fan 40,000 BTUs The heat dissipation totals can be reduced, as follows: • The vacuum unit may be located outside the print production area, which reduces the overall heat dissipation accordingly. • Make sure to keep the temperature in the vicinity of the unified cooler under 30°C (86°F). This may require moving the cooler away from other heat-emitting components, such as the UV extraction fan. In addition, the area on top of the cooler should be kept clear to enable proper heat dissipation. Temperatures above 30°C (86°F) around the cooler will prevent the cooling system from functioning properly. • The heat produced by the UV extraction fan is typically removed from the production area via the ventilation system connected to the fan. 42 HP Scitex FB10000 Site Preparation Guide, Rev. 2