HP Scitex FB10000 Site Preparation Guide Rev. 2 - Page 26

Provision for an Eye Wash Station, Provision for First Aid Treatment, at all times.

|

View all HP Scitex FB10000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

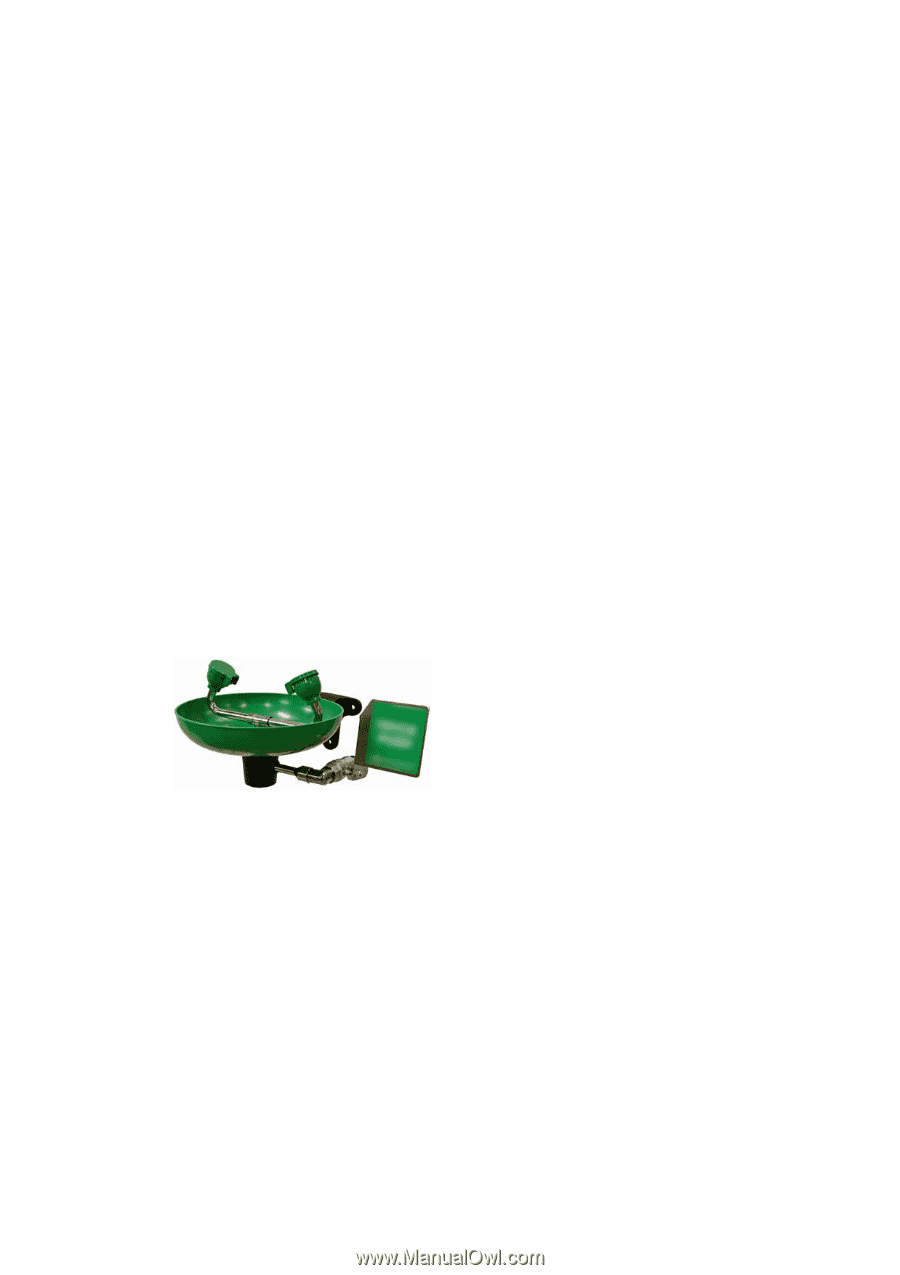

This container must be electrically grounded during transfer of liquids into or from the container. If solvent-soaked rags or absorbents are used to clean the area, dispose of them in a closed fireproof container labelled as hazardous waste. Contact local fire safety, occupational safety and hazardous waste disposal regulatory agencies for information about specific storage and disposal requirements for wastes associated with the printer. Waste containers should not be discharged in sewers and are banned from landfill sites. Provision for an Eye Wash Station When installing the HP Scitex FB10000 Industrial Press, it is important to provide an eye wash station and shower. If the system operator accidently splashes ink or solvent into the eyes, he/she must be able to flush his/her eyes immediately with copious amounts of clean water or sterile eye-wash solution, and maintain flushing for a minimum of 15 consecutive minutes. In case ink or solvent splashes onto the skin, the operator should flush it using a shower. The provision of these facilities may help to reduce the risk of irritation and possible damage to the eyes and/or skin. Eye wash facilities may be provided by plumbing a system into a specific area (reasonably close to the print production area), or installing a commercially available eye wash station. These facilities should be located at a distance of no more than 15 m (50 ft) from the print production area, and unobstructed access should be maintained at all times. The services of a plumber will be required for installation of the types of eye wash fountains shown below (see Figure 3-2). Alternatively, commercially available eye wash products (eye wash bottles containing sterile solution or sealed flushing systems) may be used. Figure 3-2 Eye Wash Station Provision for First Aid Treatment Provision of additional first aid equipment and suitable washing facilities should be in accordance with the local authority regulations and recommendations in the country of installation. 18 HP Scitex FB10000 Site Preparation Guide, Rev. 2