HP Scitex FB10000 Site Preparation Guide Rev. 2 - Page 47

Air Compressor Requirements, Environmental Requirements, Lighting

|

View all HP Scitex FB10000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 47 highlights

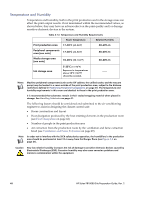

Air Compressor Requirements Table 4-11 Air Compressor Requirements Requirement Value Operating pressure 7-8 bar (101.5-117.6 psi) Flow rate Minimum of 1200 liters/min. (43 CFM) Air cleanliness The air should be filtered to 5 microns before reaching the FB10000 press. Reservoir size 400 liters (106 gal.) Air Dryer Requirements Table 4-12 Air Dryer Requirements Requirement Value Operating pressure 7-8 bar (101.5-117.6 psi) Flow rate Minimum of 1200 liters/min. (43 CFM) Dew point 2°C (35.6°F) Environmental Requirements Lighting Whenever the FB10000 press is in operation, the print production area should be well illuminated to provide the operator with optimal conditions for checking print production (color, alignment, etc.). Follow the guidelines described below to avoid ink curing when the printing bridge is raised to its vertical position: • Customer sites that are illuminated with bulbs containing mercury (for example, fluorescent and metal halide bulbs; fluorescent is recommended) should use appropriate filtering to prevent radiation peaks below 400 nm. Filtering typically consists of plastic covers over the lamp housing. • Avoid exposing the printing bridge to direct sunlight. Any windows in the vicinity of the FB10000 press should be filtered sufficiently to block 99.97% of the UV light that passes through them. Note If alterations need to be made to the customer site to conform with these guidelines, the customer in the meantime must wipe the print heads and perform light maintenance each hour while the bridge is raised. Chapter 4 - Site Planning 39