HP Scitex FB10000 Site Preparation Guide Rev. 2 - Page 29

Shipping and Delivery, Preparing the Site, Shipping Crates

|

View all HP Scitex FB10000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

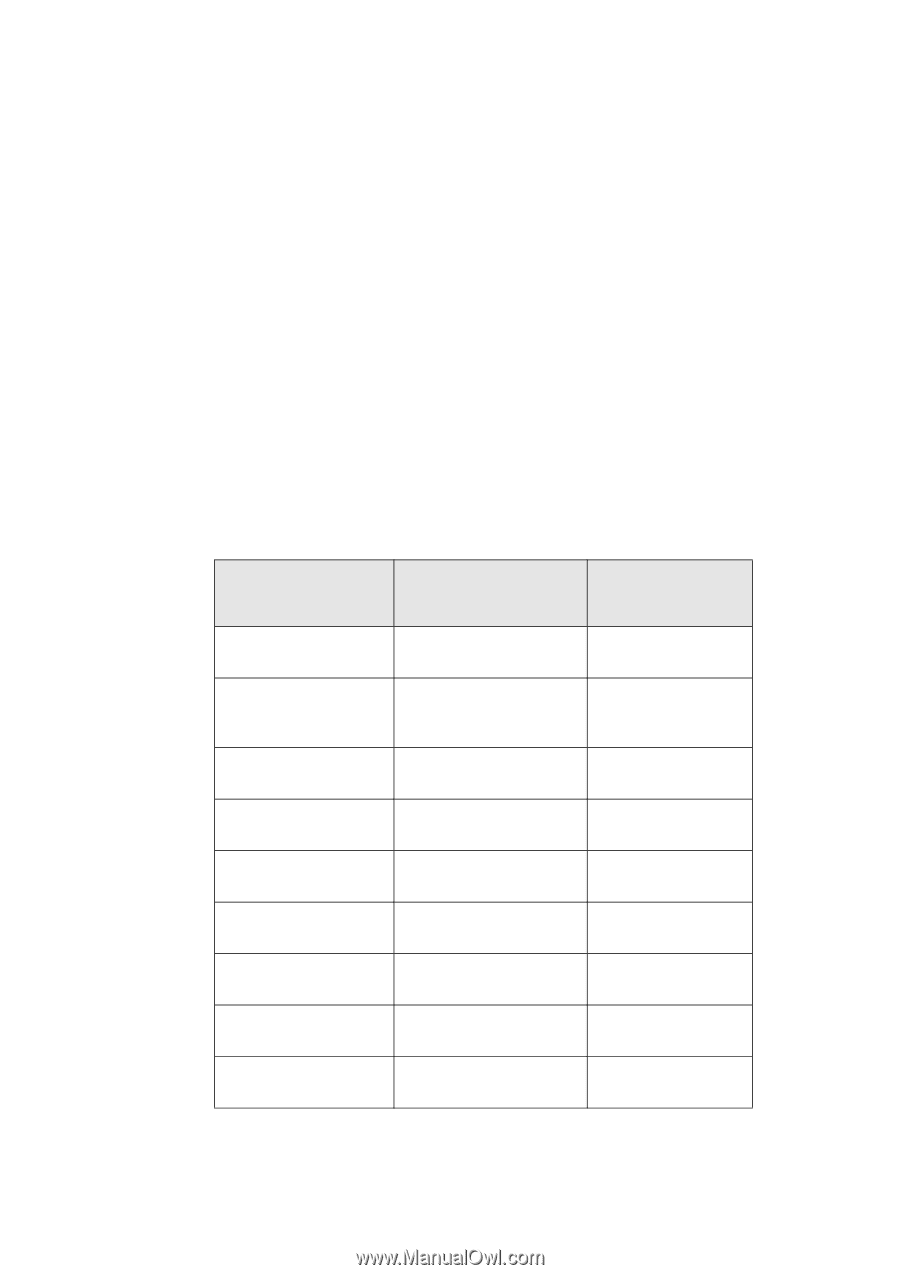

Shipping and Delivery The customer is responsible for providing professional carriers to assist in unloading the components of the FB10000 printing system and moving them to the site. The carriers should also assist HP Scitex personnel in unpacking the equipment. For details refer to Chapter 4, Machine Delivery and Rigging on page 59. Preparing the Site The customer is responsible for completing any construction work and painting prior to installation. In addition, the site should be properly cleaned prior to installation. The print production area in particular should be free from dirt and dust. Due to regulations the floor should be concrete. Tiles floors are not recommended. Wood and metal floors are not allowed. Shipping Crates Table 4-2 describes the shipping crates for the FB10000 system. Table 4-2 Dimensions and Weight of HP Scitex FB10000 Industrial Press Shipping Crates Crate Contents Dimensions (packed) LWH Weight of Crate (packed) Machine Loader, Unloader, Top Bridge Hood, and UV Covers Bridge Front and Rear Hoods, IDS Cabinet Unified Cooler, UV Extraction Fan UV Electrical Cabinet Vacuum Pump Media Loading Table Unloader Lift 1080 x 231 x 230 cm 425 x 91 x 91 in. 384 x 131 x 180 cm 151 x 52 x 71 in. 230 x 181 x 219 cm 91 x 71 x 86 in. 216 x 106 x 174 cm 85 x 42 x 69 in. 103 x 92 x 228 cm 41 x 36 x 90 in. 168 x 114 x 156 cm 66 x 45 x 61 in. 331 x 176 x 45 cm 130 x 69 x 18 in. 362 x 144 x 130 cm 143 x 57 x 51 in. 338 x 175 x 66 cm 133 x 69 x 26 in. 8260 kg 18210 lbs. 785 kg 1731 lbs. 1333 kg 2939 lbs. 547 kg 1206 lbs. 428 kg 944 lbs. 554 kg 1221 lbs. 540 kg 1191 lbs. 570 kg 1257 lbs. 1210 kg 2668 lbs. Chapter 4 - Site Planning 21