Brother International IntelliFax-3550 Service Manual - Page 38

Eraser lamp ON/OFF signal, ware malfunction.

|

View all Brother International IntelliFax-3550 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 38 highlights

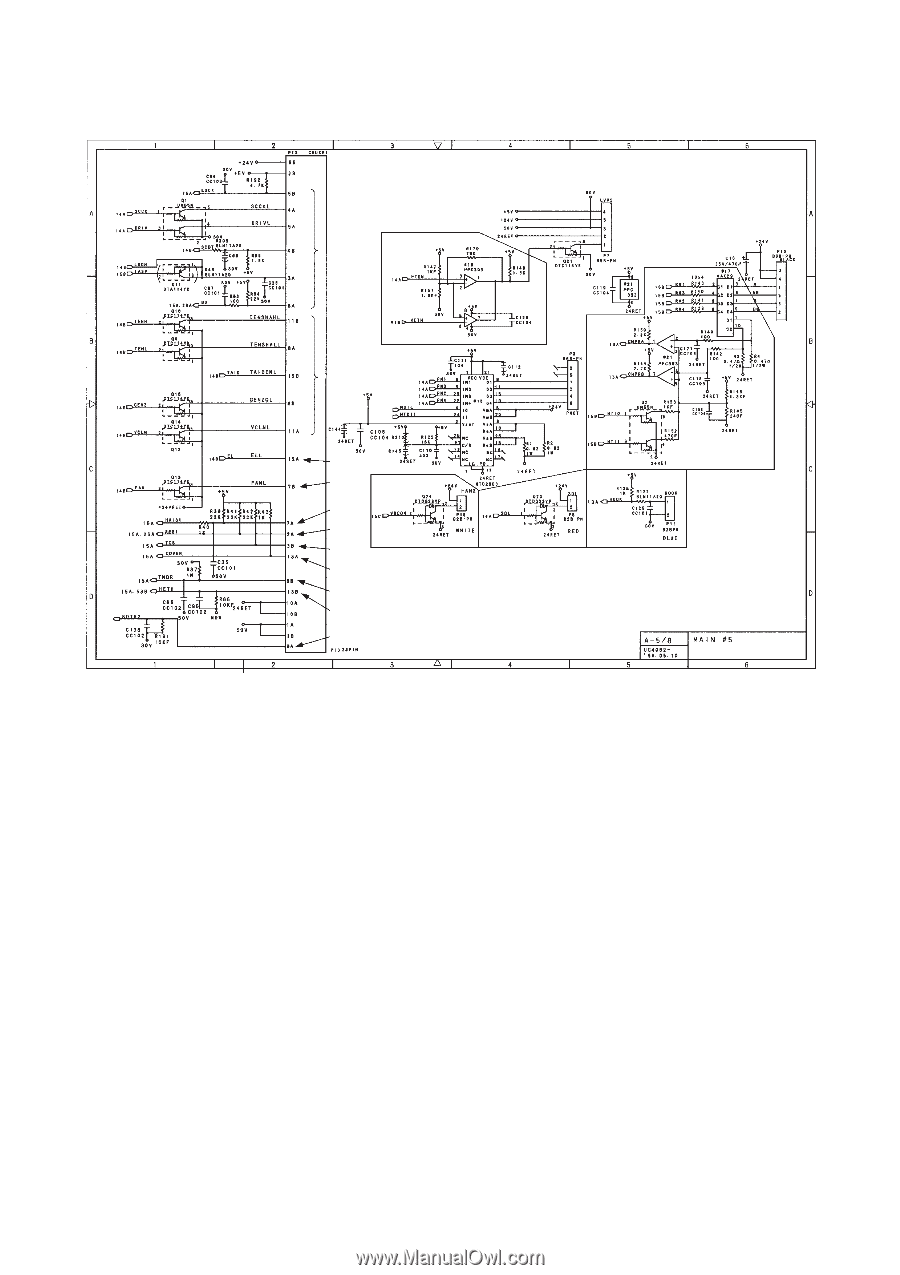

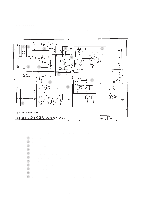

1 3 1-1 2 1-2 1-3 1-4 5 1-5 1-6 1-7 1-8 1-9 1-10 1-11 4 7 6 8 Main PCB Circuit Diagram 5/7 1 Connector for the relay PCB 1-1: Laser drive signals 1-2: High-voltage power supply control signals 1-3: Eraser lamp ON/OFF signal 1-4: Fan 1 control signal 1-5: Signal input from the paper ejection sensor 1-6: Signal input from the registration sensor 1-7: Signal input from the sheet feeder cover sensor 1-8: Signal input from the cover sensor 1-9: Signal input from the toner sensor 1-10: Signal input from the heater thermister 1-11: Signal input from the toner thermister 2 Heater control circuit which prevents the heater from overheating due to ASIC or software malfunction. (The ASIC controls the HTON signal with the hysteresis characteristics for stabilized heater control.) 3 Connector for the low-voltage power supply 4 Main motor driver which controls recording paper feeding and drum rotation. 5 Fan 2 driver circuit 6 Paper pull-in solenoid circuit 7 Scanner motor driver and its control circuitry 8 Signal input from the hook switch III - 19