Brother International IntelliFax-3550 Service Manual - Page 68

High-voltage Power Supply PCB and Fan 1, for any toner particles, paper dust or dirt

|

View all Brother International IntelliFax-3550 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 68 highlights

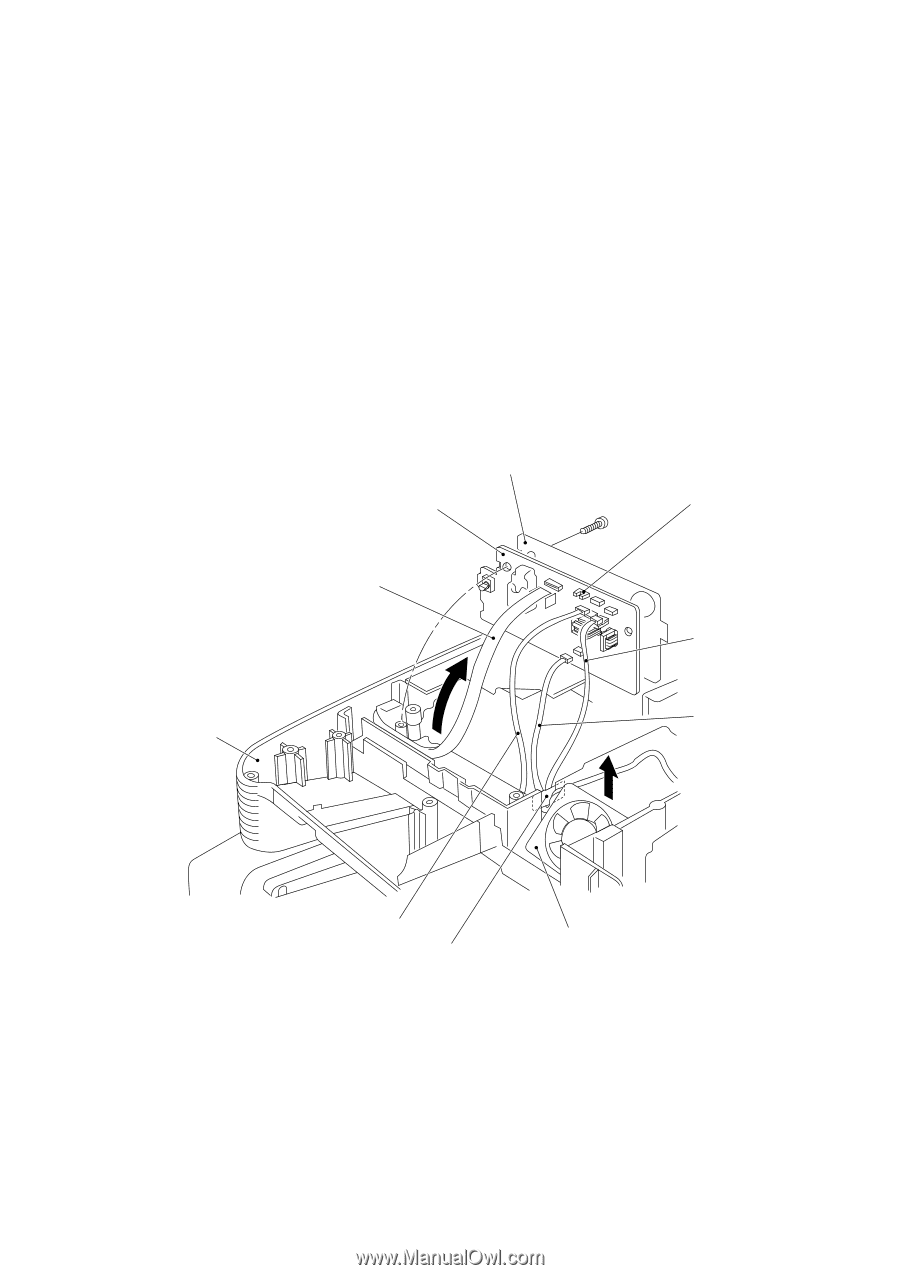

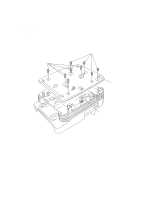

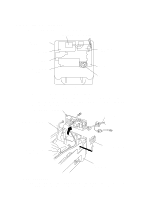

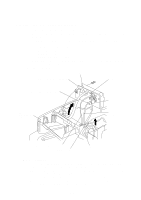

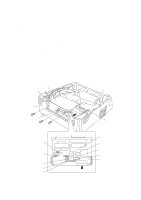

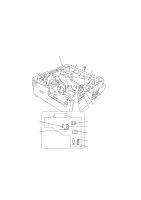

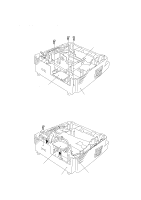

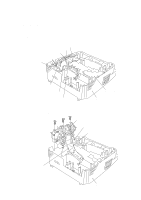

1.14 High-voltage Power Supply PCB and Fan 1 (1) Remove the screw and the insulation film. (2) While pressing down the high-voltage power supply PCB, slightly shift it to the front of the machine. (3) Slightly lift up the high-voltage power supply PCB and disconnect the following four things: • Relay-high-voltage flat cable (12-pin) • Eraser harness (4-pin) • Fan harness (3-pin) • Drum grounding harness (2-pin) NOTE: The fan harness and the drum grounding harness pass through the slot below the fan motor film. (4) Take out the fan 1. Insulation film High-voltage power supply PCB Paper ejection sensor Relay-high-voltage flat cable Fan harness Main cover (placed upside down) Drum grounding harness (Front) Eraser harness Fan motor film Fan 1 s Reassembling Notes • Before reinstalling the high-voltage power supply PCB, check the high-voltage contacts for any toner particles, paper dust or dirt, and clean them out. • When reassembling the above parts, make sure that the harnesses are routed on the main cover as illustrated in Section 1.23. • Once the fan motor film is removed, you are recommended to use a new film. • When setting the fan 1, be careful with the installation direction. The name plate should be face-up (when the equipment is placed upside down). IV - 18