HP 12C#ABA hp 12c_solutions handbook_English_E.pdf - Page 140

Miscellaneous, Learning Curve for Manufacturing Costs

|

UPC - 492410746430

View all HP 12C#ABA manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 140 highlights

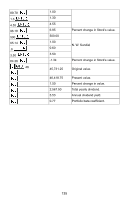

Miscellaneous Learning Curve for Manufacturing Costs Many production process costs vary with output according to the "learning curve" equation. The production team becomes more proficient in manufacturing a given item as more and more of them are fabricated and costs may be expected to decrease by a predictable amount. The learning factor, r, characterizes the learning curve. For instance, if r=.80 the curve is called an 80% learning curve. It is readily apparent that the learning, or experience curve, has many uses in setting production standards, forecasting costs, setting prices, etc. Note, however, that the learning factor may change, especially after large numbers have been produced. It the cost of the first unit of a run, C1, and the learning curve factor, r, are known, the following procedure can be used to calculate the cost of the nth item: 1. Key in the cost of the first item, C1 and press . 2. Key in the number of units produced, n, and press . 3. Key in the learning factor, r, and press 2 . 4. Then press to calculate the cost of the nth unit, Cn. Example 1: An electronic manufacturer begins a pilot run on a new instrument. From past experience he expects the process to have a learning factor, r, or 0.90. If the first unit costs $875 to produce, what is the expected cost of the 100th unit? Keystrokes Display 875 875.00 100 100.00 .9 2 -0.15 434.51 Cost of the 100th unit. If the cost of the first unit, C1, and the nth unit, Cn, are known the learning factor may be calculated. In addition, it is possible to calculate Cij, the average cost of the ith thru jth unit. These calculations may be rapidly done with the following HP-12C program: KEYSTROKES DISPLAY 139