Kyocera FS-1128MFP Service Manual - Page 132

(3) Dropouts., (4) Black dots., (5) Black horizontal streaks., Defective transfer bias output.

|

View all Kyocera FS-1128MFP manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 132 highlights

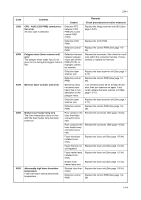

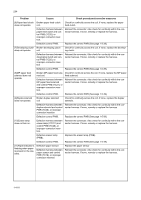

2JN (3) Dropouts. Print example Causes ABC 123 Defective developing roller (developing unit). Defective drum unit. Defective fuser unit (heat roller or press roller). Defective paper specifications. Defective transfer roller installation. Defective transfer bias output. Check procedures/corrective measures If the defects occur at regular intervals of 62.8 mm/2 1/2" (See page 2-4-3), the problem may be the damaged developing roller (in the developing unit). Replace the developing unit (See page 1-5-29). If the defects occur at regular intervals of 94 mm/3 11/16" (See page 2-4-3), the problem may be the damaged drum (in the drum unit). Replace the drum unit (See page 1-5-30). If the defects occur at regular intervals of 73.162 mm/2 7/8", or 78.5 mm/3 1/16" (See page 2-4-3), the problem may be the damaged heat roller or press roller (in the fuser unit). Replace fuser unit (See page 1-5-34). Paper with rugged surface or dump tends to cause dropouts. Replace paper with the one that satisfies the paper specifications. The transfer roller must be supported by the bushes at the both ends. Clean the bush to remove oil and debris. Replace the transfer roller if necessary (See page 1-5-32). Replace the high voltage PWB or control PWB (See page 1-545 or 1-5-39). (4) Black dots. Print example Causes ABC 123 Defective drum unit or developing unit. Check procedures/corrective measures If the defects occur at regular intervals of 94 mm/3 11/16" (See page 2-4-3), the problem may be the damaged drum (in the drum unit). Replace drum unit (See page 1-5-30). If the defects occur at random intervals, the toner may be leaking from the developing unit or drum unit. Replace the developing unit or drum unit (See page 1-5-29 or 1-5-30). (5) Black horizontal streaks. Print example Causes ABC 123 Defective drum unit's ground. Defective drum unit. Check procedures/corrective measures Check that the drum shaft and the grounding tab (machine) are in good contact. Apply the grounding tab a small amount of electroconductive grease as required. Replace the drum unit (See page 1-5-30). 1-4-14