HP Latex 3200 Users Guide - Page 185

Substrate, Color calibration, Calibrate, Show all

|

View all HP Latex 3200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 185 highlights

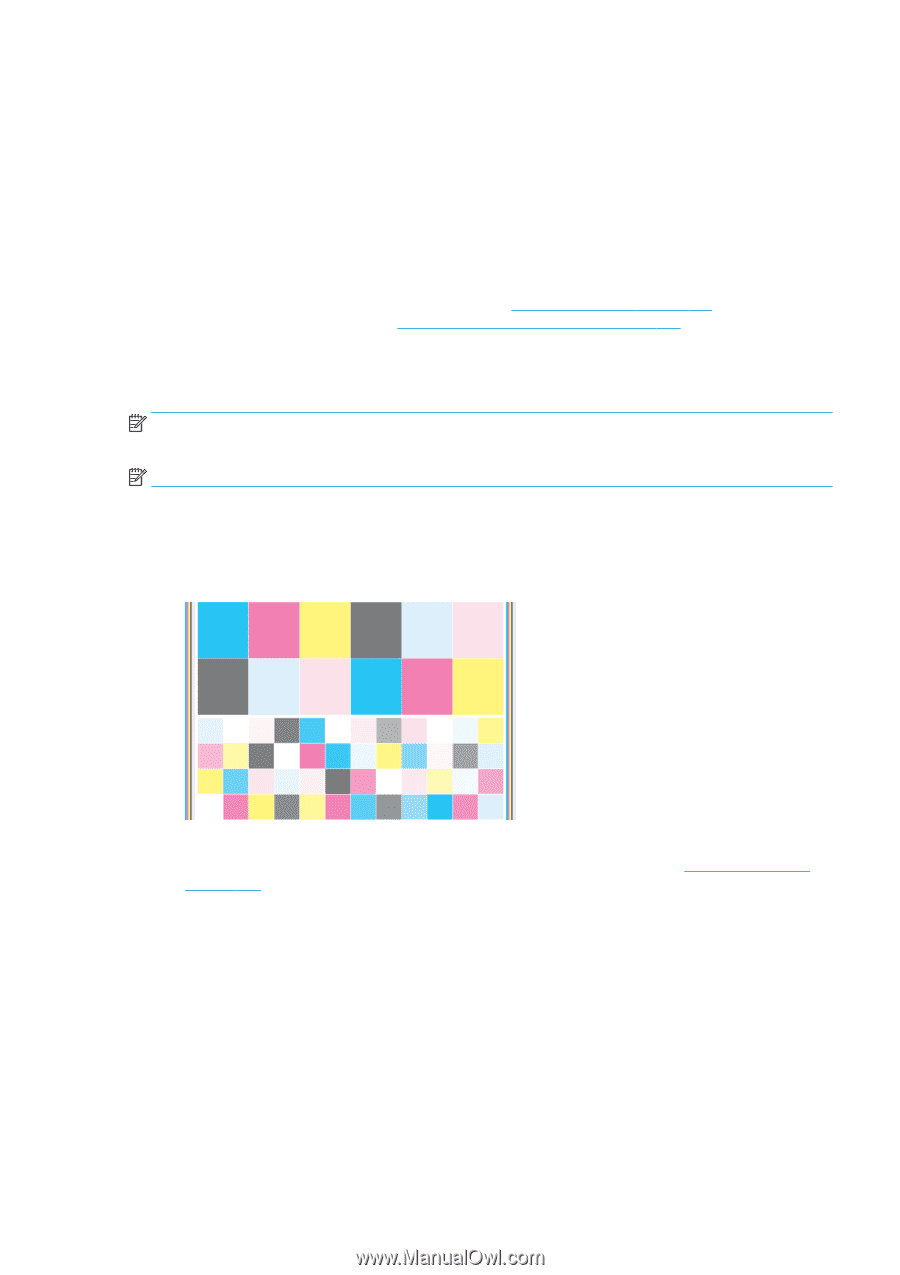

Color calibration sets the ink restriction and linearization, which varies with the drop weight of the printhead. This calibration has been designed to provide consistency as the printhead ages (drop-weight degradation) and from one printer to another. For example, to reach a maximum cyan density of 0.6, one printhead may require 3 drops while another one may require 3.5 drops (lower drop weight). There are no factory-reference color-calibration values in the printer or within the presets: the first calibration for each substrate sets the color reference for future calibrations. The future calibrations will therefore try to match the colors of the first calibration. In this way you maintain consistency as the printhead ages. Good nozzle health is important, and the printheads should also be as new as possible for best performance when you make the first calibration. It is also important to have the printheads well aligned (see Align the printheads on page 172), and to make sure the substrate is advancing correctly (see Substrate-advance compensation on page 181), otherwise the color pattern may appear blurry or with slightly different colors. To start color calibration from the Internal Print Server, select Substrate > Color calibration, then click the Calibrate button. NOTE: Only non-porous substrates wider than 61 cm (24 in) can be calibrated. Porous substrates cannot be calibrated. NOTE: Color calibration is not recommended when the carriage beam is in a higher position than normal. The calibration process is fully automatic and can be performed unattended after you have loaded substrate of the type you wish to calibrate. The process takes about 15 minutes and consists of the following steps: 1. The color calibration test chart is printed, which contains patches of different densities of each ink used in your printer. 2. The test chart is scanned and color-measured using the embedded spectrophotometer. If the scan cannot be completed successfully, a message is displayed by the Internal Print Server; see Color calibration fails on page 407. 3. From the measurements made by the spectrophotometer, the printer calculates the necessary correction tables to apply to your print jobs for consistent color printing on that substrate type-except in the case of the first calibration, which sets the reference for later ones. Calibration should be done in any of the following circumstances: ● Whenever a new substrate type is introduced that has not yet been calibrated: to set the reference. ● Whenever you notice excessive color differences between prints. Such color differences can be caused by aging and wear of the printheads, installing new printheads, changes in substrate characteristics between one roll and another, changing environmental conditions, and so on. You can check the color calibration status of your substrates with the Internal Print Server: select Substrate > Color calibration > Show all. ENWW Color calibration 179