HP Latex 3200 Users Guide - Page 398

Bleed, halo, wicking, Low gloss, haze, appear

|

View all HP Latex 3200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 398 highlights

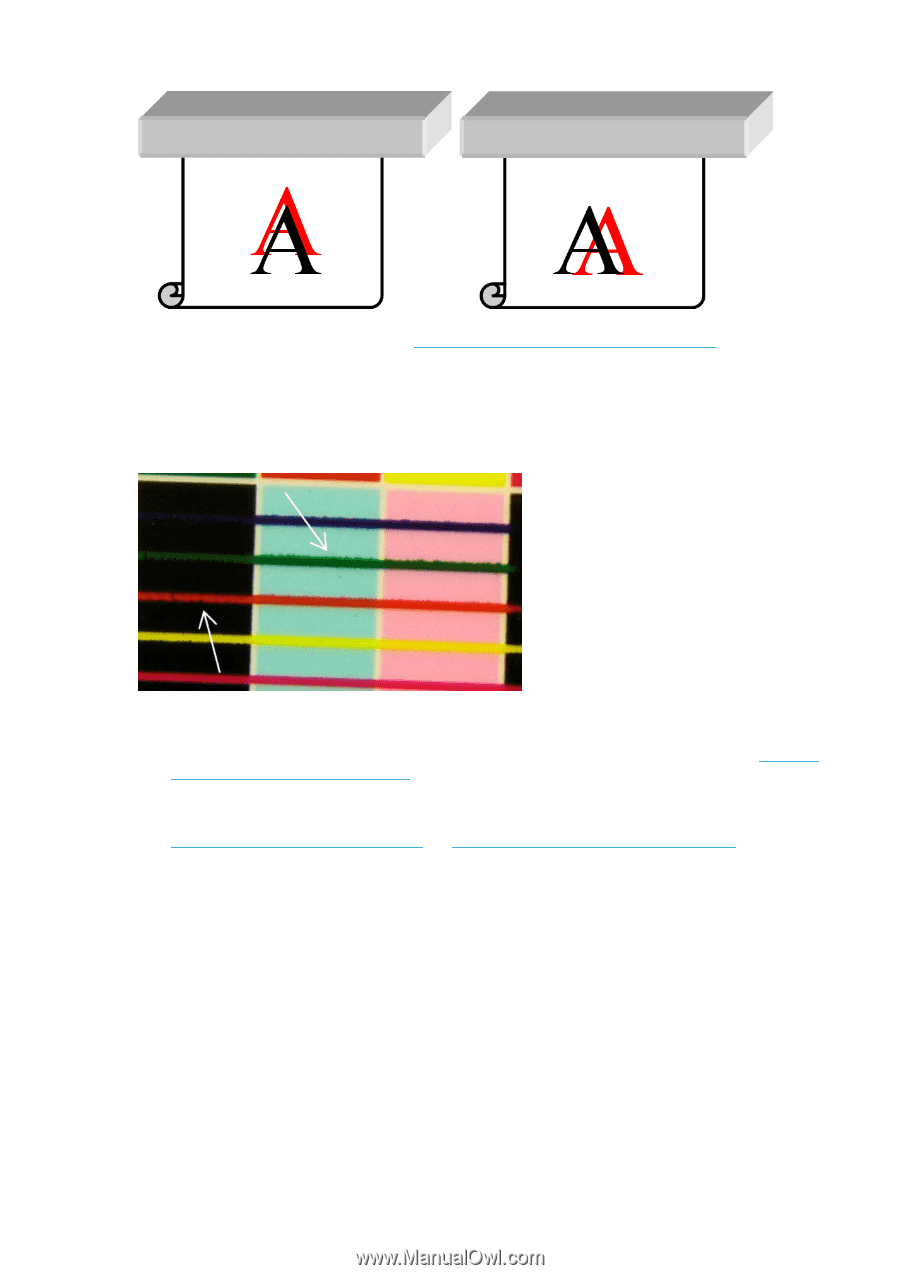

Color misalignment is most likely to be caused by printhead misalignment. To check printhead alignment, print the printhead alignment diagnostics plot (see Printhead alignment diagnostics plot on page 175). Bleed, halo, wicking Sometimes a small color migration may be observed at the border between different colors (bleed). It may also happen at the border between a color and blank substrate (no ink), reducing the sharpness of the shape. On some substrates, a gloss halo can be observed at the border between colors. There are three likely causes: ● Optimizer misalignment: There may be misalignment between the optimizer printhead and the other printheads. To check the printhead alignment, print the printhead alignment diagnostics plot (see Printhead alignment diagnostics plot on page 175). If necessary, perform a manual alignment, then reprint the printhead alignment diagnostics plot. If the problem is in the substrate axis direction, it may also be caused by incorrect substrate advance. See Substrate-advance test print on page 182 and Substrate-advance compensation on page 181. ● Optimizer level, which may be too low for this substrate and ink density. Other associated defects may also appear, such as coalescence or grain in the area fills due to low wetting of the ink on the substrate. You can correct this problem by increasing the optimizer percentage in the substrate preset. ● Drying power, which may be too low for this substrate and ink density. Other associated defects may also appear, such as coalescence or grain in the area fills due to low wetting of the ink on the substrate. You can correct this problem by increasing the drying power leading/trailing percentages in the substrate preset. Low gloss, haze On glossy substrates, the print may have lower gloss than expected, which is probably due to the optimizer level. To investigate and correct this problem, try increasing and decreasing the optimizer percentage in the substrate preset. 392 Chapter 11 Troubleshoot print-quality issues ENWW