Sharp AR M550N Installation Manual - Page 20

Carry out the print off center adjustment - service manual

|

View all Sharp AR M550N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 20 highlights

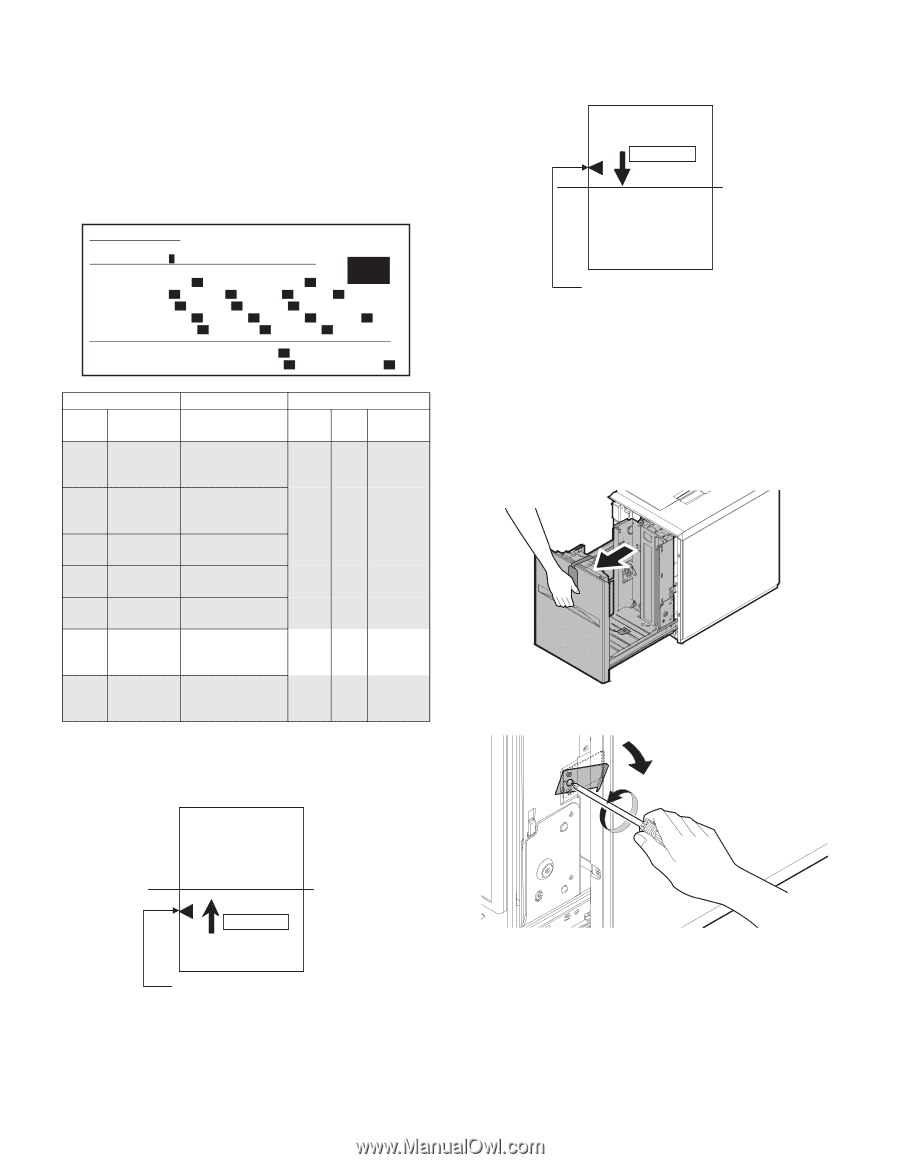

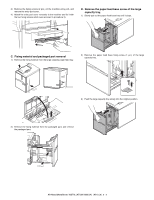

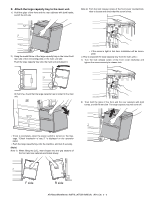

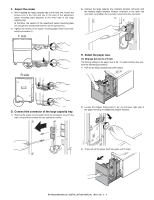

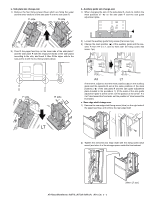

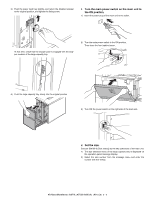

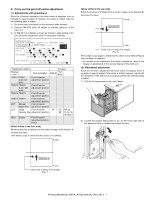

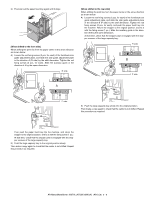

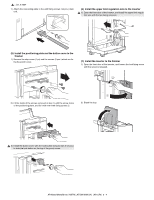

K. Carry out the print off center adjustment (1) Adjustments with simulations Since the off-center adjustment has been made at shipping, there is normally no need to adjust. If, however, the center is shifted, carry out the following steps to adjust. 1) Set a test chart (document) on the document table properly. 2) Execute SIM 50-5 (Print off center) by the key operation of the main unit. 3) In SIM 50-5, the display is shown as follows to allow setting of the print off center adjustment value for each paper feed tray. SIMULATION 50-5 LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START. 0.TRAY SELECT 1 1.PRINT START (ADJUSTMENT DATA) 2 LEAD EDGE: 2.RRCB 50 20.SIDE2 ADJ. 50 RESIST: 3.T1 50 4.T2 50 5.T3 50 6.T4 50 7.BPT 50 8.LCC 50 9.ADU 50 OFF CENTER: 10.T1 50 11.T2 50 12.T3 50 13.T4 50 14.BPT 50 15.LCC 50 16.ADU 50 (VOID SETTING) 17.LEAD_EDGE(DENA) 35 18.TRAIL_EDGE(DENB) 35 19. FRONT/REAR 35 Adjustment position Set value Display item Item description Default Set range TRAY1 TRAY1 (LCC left side) Print off center adjustment position TRAY2 TRAY2 Print off center (LCC right adjustment position side) TRAY3 TRAY3 Print off center adjustment position TRAY4 TRAY4 Print off center adjustment position BPT Manual Print off center paper feed adjustment position LCC Large Print off center 50 0 to Shift by capacity tray adjustment position 99 0.1mm for set value 1 ADU Duplex Print off center adjustment position (ADU) [When shifted to the front side] When the print line is shifted from the center of paper in the direction A: Increase the value. Then make a copy to check that the center is not shifted. R side [When shifted to the rear side] When the print line is shifted from the center of paper in the direction B: Decrease the value. R side Direction B F side Center line of image (first image) (Fig. 2) Then make a copy again to check that the center is not shifted. Repeat this procedure as required. ∗ For details of the adjustment and check procedures, refer to the chapter of adjustments in the Service Manual of the main unit. (2) Mechanical adjustment Since the off-center adjustment has been made at shipping, there is normally no need to adjust. If the center is shifted, however, adjust with the simulation. If the shift is not recovered, perform the following steps to adjust. 1) Pull out the large capacity tray until it stops. 2) Loosen the stopper fixing screw (1 pc.) on the lower right side of the paper feed tray to disable the stopper function. Direction A F side Center line of image (first image) (Fig. 1) AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 7