HP Designjet L26100 HP Designjet L26500/L26100 Printer Series - User's Guide - Page 69

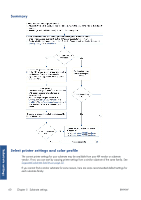

The various settings mentioned above are described below., Add a new substrate, Substrate, family

|

View all HP Designjet L26100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 69 highlights

Substrate family Warm-up drying temperat ure offset Warm-up curing temperat ure Warm-up curing temperat ure offset Cooldown drying temperat ure Cooldown drying temperat ure offset Cooldown curing temperat ure Cooldown curing temperat ure offset Minimum drying power Low-temp. 10 80 0 75 0 85 0 0 Mesh 10 85 0 80 0 85 0 0.7 The various settings mentioned above are described below. Setting Warm-up drying temperature Warm-up drying temperature offset Warm-up curing temperature Warm-up curing temperature offset Cool-down drying temperature Cool-down drying temperature offset Cool-down curing temperature Cool-down curing temperature offset Minimum drying power Description If too low If too high The base temperature that the substrate in the print zone must reach before printing starts. This setting is determined by the RIP. You cannot change it. This offset is added to the base warm-up drying temperature, and the total is displayed in the front panel while the printer is preparing to print. Bleeding or coalescence may appear in the first 200-300 mm of the print. A longer time to start printing is required. Vertical banding or ink smears may occur. The base temperature that the substrate in the curing zone must reach before printing starts. This setting is determined by the printer. You cannot change it. This offset is added to the base warm-up curing temperature, and the total is displayed in the front panel while the printer is preparing to print. The beginning of the print is not fully dry, or looks oily. Substrate degradation (blisters, adhesive detachment) at the beginning of the print. The base temperature at which the substrate can be under the drying module without being damaged. At the end of a job, the substrate is not stopped until this temperature is reached. This setting is determined by the printer. You cannot change it. This offset is added to the base cool-down drying temperature. A long time is needed to finish the print. The substrate at the beginning of the next print may be damaged, because it has stopped moving under too high a temperature. This case is uncommon. The base temperature at which the substrate can be under the curing module without being damaged. At the end of a job, the substrate is not stopped until this temperature is reached. This setting is determined by the printer. You cannot change it. This offset is added to the base cool-down curing temperature. A long time is needed to finish the print. The end of the print may be damaged if the cutter is disabled. The minimum power applied in the drying module while printing, so the substrate does not cool too much in lightly inked areas. A heavily inked area that comes after a lightly inked area will have bleeding or coalescence defects. The substrate is damaged in blank or lightly inked areas of the print, especially with a high number of passes. Substrate settings ENWW Add a new substrate 65