HP Designjet L26100 HP Designjet L26500/L26100 Printer Series - User's Guide - Page 91

Glossary, High Density Polyethylene.

|

View all HP Designjet L26100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 91 highlights

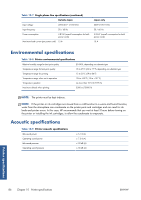

Glossary Airflow Air is blown through the printing zone to speed up the drying process. Back tension The backwards tension applied to the substrate by the input spindle, which must be constant across the width of the substrate. Too much or too little tension may cause substrate deformation and print quality defects. Bidirectional Bidirectional printing means that the printheads print while moving in both directions. This increases the speed of printing. Bleeding A print-quality defect that occurs when the ink spreads on the substrate across areas of different colors. Coalescence A print-quality defect that occurs when the ink spreads on the substrate within an area of the same color. Cockle A substrate condition in which it is not lying perfectly flat, but rises and falls slightly in shallow waves. Color accuracy The ability to print colors that match the original image as closely as possible, given the fact that all devices have a limited color gamut and might not be able to match certain colors precisely. Color consistency The ability to print the same colors in a particular print job, from print to print and from printer to printer. Curing The substrate is heated in the curing zone to coalesce the latex, creating a polymeric film which acts as a protective layer, while at the same time removing the remaining co-solvents from the print. Curing is vital to ensure the durability of the printed images. Too high or too low a curing temperature may cause print quality defects. Cutter A printer component that slides back and forth across the platen to cut the substrate. Drying The substrate is heated in the printing zone to dry the ink and fix the image to the substrate. Too high or too low a drying temperature may cause print quality defects. Edge holder A metal piece designed to prevent the edge of the substrate from rising while printing is in progress. Firmware Software that controls your printer's functionality and is stored semi-permanently in the printer (it can be updated). Gamut The range of colors and density values reproducible on an output device, such as a printer or monitor. HDPE High Density Polyethylene. ENWW Glossary 87